Rubber compounds, or thermoplastic elastomers (TPEs) have significantly improved the quality of a wide range of products. TPEs, being a group of rubber-like materials, can be moulded into custom shapes and have been preferred for medical application.

ELASTO Sweden, part of the HEXPOL TPE group, presented the latest offering from their Mediprene portfolio of thermoplastic elastomers for medical device applications. The group has developed TPE compounds with both high levels of transparency as well as vibrant colours.

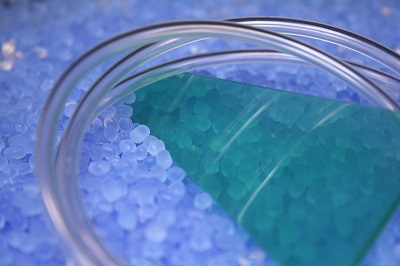

The Mediprene compounds offer crystal clear transparency with the added benefit of colour to give an attractive, enriched appearance. The ability to clearly see through a product to monitor the patient is an important feature for many medical devices such as face masks. Transparent TPEs can also be used in tubing and dental applications. In medical devices and pharmaceutical packaging colour is also often used functionally for product identification, to differentiate products with different uses or sizes.

The Mediprene compounds offer crystal clear transparency with the added benefit of colour to give an attractive, enriched appearance. The ability to clearly see through a product to monitor the patient is an important feature for many medical devices such as face masks. Transparent TPEs can also be used in tubing and dental applications. In medical devices and pharmaceutical packaging colour is also often used functionally for product identification, to differentiate products with different uses or sizes.

The vibrant colours achievable with coloured Mediprene TPE compounds allow brand owners to add value to their products and create visual appeal. A blue or green colour is often used in medical transparent or translucent products to disguise the yellowing phenomena that can be caused by for example gamma sterilization.

The Mediprene TPE compounds were developed in response to an increasing interest in transparent compounds from the medical market. The coloured transparent compounds are made from medical grade raw materials only. The colour masterbatch supplier has been selected with care, ensuring that not only the colorants and carriers are compliant with USP Class VI or corresponding parts of ISO 10993 but also that the masterbatches are manufactured under rigorous controls with regard to traceability, consistency and change control, thereby fitting the Mediprene concept at ELASTO Sweden’s ISO 13485 accredited facilities.

Consistency and reproducibility

A fully colour compounded TPE gives a perfectly dispersed, consistent colour with a correct and reproducible addition level. Mediprene coloured transparent compounds ensure colour reproducibility and deliver a compound ready for use, with no additional steps for the moulder or extrusion company. A series of Mediprene transparent TPE compounds has been developed with hardnesses ranging from 30 to 90 Shore A in 5 Shore A increments.

Niklas Ottosson, medical technical manager for ELASTO Sweden commented, “With the Mediprene TPE compounds the benefits of colour and crystal clear transparency are united, opening up further design and brand identification possibilities for the medical device market. Our customers also have the security of a fully compounded TPE, manufactured from medical grade raw materials only, matched to their requirements and ready for use.”

Kjell Fagerström, managing director at ELASTO Sweden added, “The development of coloured, transparent medical TPEs is part of our on-going commitment to supply leading quality TPE products and the highest levels of support. These compounds are possible due to the rigorous standards and controls of our compounding processes. This year we have further strengthened our local support abilities, with the creation of a new office in Belgium to serve our medical customers in Germany, Austria, Switzerland and Benelux. We have also recently announced our investment in a new twin-screw TPE production line at our facility in Åmål, Sweden.”

HEXPOL TPE brings together the ELASTO businesses in Sweden, UK and China and Müller Kunststoffe in Germany. The company has been at the forefront in the development and manufacture of custom formulated thermoplastic elastomers (TPE) and complimentary compounds. The comprehensive portfolio covering TPS, TPO, TPV, TPU, soft PVC, cork compounds and masterbatch is led by global brands Dryflex®, Mediprene®, Lifoflex®, EPSeal®, Lifolit®, Lifocork®, Lifobatch® and Lifoprene®.

NEW BALANCE

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login