Today we have an overall increased awareness for improved quality for all kinds of products. Even smallest defects need to be detected before they reach the final customer. Therefore, the manufacturing industry has to improve production processes and the overall logistics in terms of quality, safety and the control of cost. A wide range of different technologies is used nowadays in order to control and assure the quality in the production process. However, the future lies in new high sophisticated technologies, implemented in one system. A main example for quality insurance is the food industry. X-rays are commonly used on the assembly line to weed out food products that contain foreign objects or do not meet a company’s quality standards [1]. By X-raying, some of the nutrients may be lost. However, the final product benefits from a reduced risk of causing foodborne illness and boosts a longer shelf life.

Rising quality demands in the plastic industry

Plastics, and especially high sophisticated engineering plastics, require the highest quality standards. Due to the continuously increasing requirements within the industrial production, it is necessary to detect and sort out irregularities and impurities of decreasing size. Impurities of 50 µm may already cause damage to production systems or end products with high follow-up costs. An example from the cable industry: For the production of a high-voltage subsea cable, it is of crucial importance to use highly, or so called super clean, material. A contamination during the production can lead to a massive failure [2] of the cable once it is positioned under sea level and can cost millions. For the cable industry, it is important to distinguish between different types of contamination, such as metallic or organic contamination. Therefore, latest norms and standards, such as the Chinese standard IEC 62067 (for 150 – 500 kV) for high voltage cables, demand the exclusion of contamination from 75 µm in the processed material [3].

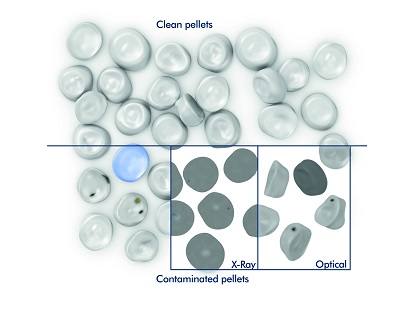

Today, there are various systems, technologies and machines available in order to inspect and sort materials. However, most of these machines are designed for the food industry. The majority of these systems are based on optical inspection technology to detect contamination on the pellet [4] [5] [6].These limitations of the optical system demand new ways and technologies to fully meet the requirements of the plastic industry. Contamination inside the pellets, especially coloured pellets, cannot be detected by optical systems. To assure 100% quality inspection, a combination of X-ray and optical technology is necessary.

The basic principle of x-ray technology is the different attenuation of raw material and impurities or faults respectively. The attenuation (µ) of the X-rays is mainly determined upon the nuclear charge of elements as well as of the thickness of the material to be inspected [7]. It is proportional to the atomic number raised to the 3rd power (µ~Z3).

Plastics consist mainly of carbon with a very low attenuation (Z=6). An iron contamination with comparatively strong attenuation (Z=26) can be detected clearly and sorted out. An additive, for example titanium dioxide, also affects the attenuation and agglomerates significantly contrast in the dispersion. This is possible because the titanium (Z=22) strongly contrasts with the plastics.

With a specific developed X-ray camera system, it is possible to detect contamination during the production process. Pictures of the plastic pellets are processed in real-time by mathematical algorithm. Differences in the attenuation are clearly identified, even for a size as small as 50 µm. By combining the analytical results of the mathematical algorithm with a certain threshold, the system clearly identifies impurities and contamination in plastic pellets (Picture 1) and sorts those out.

New optical inspection technology

Regarding the optical inspection, the lighting plays an essential role. The use of a novel light construction technique allows a particularly diffuse lighting of the material. Smallest contaminants and organic impurities are detected by modern camera technologies at industrial speed.

Powerful image-processing software is used to detect contamination with the optical system (Picture 2). Therefore, all contaminated pellets, which are above the threshold in the mathematical algorithm, are sorted out.

Further possibilities with X-ray

The plastic production processes are complex. Different materials are mixed together and there are many sources of contamination. X-ray technology does not only detect metallic impurities in plastic pellets but provides different information concerning the condition of the overall production process such as the identification of cross-contamination. This can be clearly visible due to different attenuations. A main advantage of X-ray technology is that it is colour independent. Tests show, that it is also possible to detect an organic contamination as a piece of tissue as well as a small metallic contamination. Even air holes inside the pellet, indicating a needed adaptation of the production parameters, are detected.

Experiments demonstrate the possible use of X-ray to detect agglomerations of substitutes in polyethylene pellets. X-ray is able to detect agglomerations of titanium oxide particles inside the plastic pellets that can lead to major problems while processing. It is also possible to determine the geometry in possible defects of plastic pellets – even in black polyethylene pellets.

However, there are limits of using X-ray technologies. While it is possible to distinguish a difference in the attenuation, it is more difficult to define the composition of metallic material. In order to be able to differentiate between metallic materials, further analyzing technologies would be necessary.

Conclusions

Quality standards in the plastic manufacturing industry are constantly increasing. Today even smallest contamination need to be eliminated during the production process. With X-ray and optical technology, it is possible to detect impurities of 50 µm on the surface as well as inside a plastic pellet. Combining these technologies into one system means a 100% inspection of the material flow (Picture 3).

The principle is transferable to different material types as for instance TPE. Impurities or irregularities from 50 µm are detected at common flow rates. In addition, the dispersion of additives, especially in the compounding process, is detectable. As a result, agglomerates and disturbances in the subsequent processes are avoided. Therefore, the quality can be improved significantly and a 100% inspection of all products is possible. Further developments need to be done in order to provide more information to the staff running the production and to eliminate the contamination source. Other developments will be done with regard to the size of detectable contamination. The target contamination detection size is 30 µm. IRNA

References

1. D-W Sun, Computer Vision Technology in the Food and Beverage Industries (2012)

2. Mr. Omar Monajjed, High Voltage Technical Manager, LIBAN CABLES - NEXANS, Lebanon, Effect of impurities on electric field distribution in HV XLPE insulation, Polymers in Cables 2014, Philadelphia, USA

3. J. Kjellqvist, K.P. Pang, S. Miao, Dow Europe GMBH, Horgen, Switzerland, Dow Chemical (China) Co. Ltd., Shanghai, China, Performance Requirements to Assure Reliable HV and EHV Cables, China International Conference on Electricity Distribution (CICED 2010) Nanjing (20-23 Sep. 2010)

4. Tomra demonstrates optical sorter, http://www.plasticsnews.com/article/20131030/NEWS/131039997/tomra-demonstrates-optical-sorter#, (10/2013)

5. Laura Tarrach, OCS GmbH, Pellet Scanning in “Free Fall”, Kunststoffe international (12/2010)

6. Satake, Pellet Sorter PCS600PFD, http://www.satake-usa.com/images/Pellet_Sorter_Brochure.pdf (2014)

7. Robert Fosbinder, Denise Orth, Lippincott Williams & Wilkins, Essentials of Radiologic Science (01.02.2011)

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login