Numerous trends in the oil and gas industry are shaping the direction of new cutting tool developments. For instance, parts are getting larger and materials more exotic. In addition, as the industry moves into deeper waters component precision, surface quality and process security are all ascending the priority list. With this in mind proven, high-performance tooling technologies are becoming ever more vital within the total machining solution.

A prime example of component evolution due to deeper exploration and drilling is the Christmas tree assembly, which helps monitor and control the production of a subsea well and can also manage fluids or gas injected into the well. Deep-water fields operate at depths down to 3000 m, so the Christmas tree must withstand water pressure up to 700 bar. In addition, the sour oils and gases retrieved require the use of non-corrosive, high-strength materials such as Inconel. Here, cutting tool selection becomes crucial as raw material costs mean rework or scrap is simply not viable.

Complex parts

Typical components found within Christmas tree assemblies include spool bodies, tubing hangers, valves and control unit collars. The latter, which measure around 10 m in length, are extremely demanding to machine. It is vital to maintain a high surface finish with good diametrical tolerance and high concentricity between the bores. However, CoroDrill 801 and CoroDrill 818 for deep hole machining operations are proven performers when it comes to control unit collars.

For instance, take a collar made from non-magnetic stainless steel (CMC 05.21). Cutting speeds of 70 m/min can be achieved along with feed rates of 0.20-0.24 mm/rev at 21 bar coolant pressure when solid drilling with CoroDrill 801. The result is high process security and productivity combined with excellent surface finish.

Identical cutting data can be applied when counterboring the same component using CoroDrill 818. As well as process security, the counterboring process offers superior hole straightness in tandem with wide diameter adjustability.

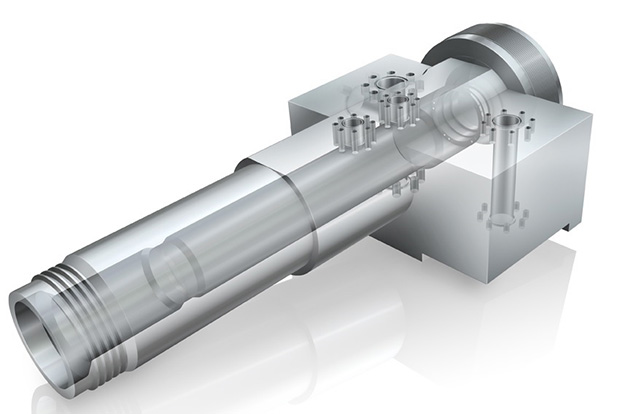

Spool body

Providing outlets to attach several different valve configurations, the main function of the spool body is to control flow from the well bore. These sizeable parts weigh around 7 tonnes and are often dual material; typically steel such as AISO/SAE 4140 with Inconel 625 internal cladding.

The main machining operations are external and internal turning. Starting with external turning of 4140 steel, a Sandvik Coromant CNMG insert in new GC4325 grade (mounted in a Coromant Capto® C8 holder) has been shown to deliver both reliability and predictable tool life, while at the same time maximising productivity. The new steel turning grade GC4325 provides unrivalled performance when it comes to process security and productivity, even at higher cutting speeds.

Rough internal boring operations on spool bodies are also challenging thanks to interrupted cuts on tough Inconel 625. Here, a combination of CNMG insert (grade GC2025), insert carrier such as DuoBore™ 821 or CoroBore® 820 XL, and Silent Tools® holder (8xD) help optimise the task by offering extended tool life. Long overhangs and productivity demands mean that increasing numbers of oil and gas machine shops are turning to Silent Tools for internal turning. By using these innovative dampened boring bars, vibration is eliminated and process security is assured without any detriment to high metal removal rates.

Tubing hanger

Attached to the topmost tubing joint in the wellhead, tubing hangers are designed to support the tubing string. The material is typically 4130 steel cladded with Inconel 625.

These parts comprise a number of features best produced using a milling cutter and helical interpolation as this is both productive and secure and avoids the interrupted cuts encountered in turning. For instance, the CoroMill® 210 high feed face and plunge mill with GC1040 inserts is a proven solution when mounted in a Capto C8 holder with Silent Tools C5 dampened adaptor.

Internal turning of tubing hangers clad with Inconel 625 again faces the familiar problems of long overhang, vibration and chip evacuation. However, Sandvik Coromant has demonstrated a number of successful solutions in this area. For example, CNMG inserts in grade GC1125 mounted in an SL exchangeable cutting head with Capto C8 interface and Silent Tools C8 dampened boring bar can perform both roughing and finishing operations. The same can be said of using CoroTurn® 570 with DNMG inserts in GC1125 grade. For the adaptor, a Silent Tools dampened boring bar (10xD) is deployed. Ultimately, these solutions offer vibration- and trouble-free machining to overcome the traditional problems of tool breakage and short tool life.

Threading operations in tubing hangers can be equally treacherous and there is a high risk of broken taps. For this reason, producing typical tubing hanger threads such as 1¼ inch 7UN-2B in 4130 steel is best facilitated by thread milling. A solution such as the CoroMill 327 thread mill with GC1025 grade inserts and Coromant Capto C8 offers a secure and productive process with no risk of tap breakage.

With regard to rough boring operations, these demand a combination of tooling to achieve the necessary productivity and precision required for Inconel-clad tubing hangers. Success has been demonstrated using a CCMT insert in grade GC1125 mounted in CoroTurn® 107. Supported by the use of dampened Duobore (and slide) and Coromant Capto, cutting data of 30 m/min speed, 0.15 mm/rev feed and 0.3 mm depth of cut is achievable.

Valves

Last but not least, Christmas tree assembly valves are used to regulate, direct or control the flow of fluids or gases by opening, closing or partially obstructing various passageways. They are made in many different sizes and materials, although most demand the machining of similar features, which include cavity bores, seat pockets and bolt holes. These also present similar challenges, such as interrupted cuts, chip evacuation/control, short/ irregular tool life and long overhangs.

Among the solutions in this area, the helical interpolation of cavity bores is recommended using the CoroMill 419 high-feed milling concept, while semi-boring with CoroBore 820 and fine boring with CoroBore 826 are also proven for valve machining applications. The Sandvik Coromant solution for valve seat pockets centres on back-facing using a Silent Tools boring bar and the CoroTurn SL modular system. For drilling bolt holes, CoroDrill 880 is highly productive.

Conclusion

The need for oil and gas is set to continue its pattern of growth over the coming decades, driven mainly by an increasing standard of living in some countries. At the same time, crude oil production from existing fields will drop over two-thirds by 2035, demanding more focus on new exploration. These facts indicate that there will be a strong need for machined oil and gas components for many years to come. Without doubt, machine shops will require the latest cutting tool technologies to win and retain lucrative contracts in this buoyant yet demanding industry.

Nike KD

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login