The Maag brands “maag pump systems”, “automatik pelletizing systems” and “maag filtration systems” are the main highlights at the company's booth located at hall 5 no. C105 at this year's edition of Arabplast. In addition, the PRIMO 200E dry-cut strand pelletizer with its cantilever bearings and an extra-large cutting width of 200 mm is on exhibit.

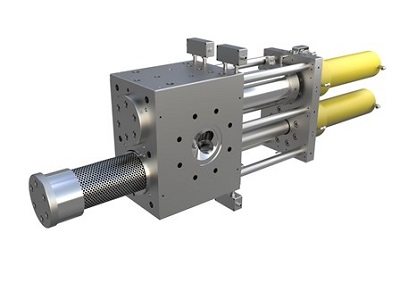

The complete system, targeted at more efficient polymer production in the mid-tier throughput range. consists of the extrex 90 extrusion pump, the CSC 116-RS arched screen changer and the brand-new SPHERO S underwater pelletizer system. The pellets produced with SPHERO S are of high quality. The whole system guarantees improved energy efficiency, great reliability and high productivity. Each of the individual system components are designed with compactness, space-saving and ease of operation in mind.

With the extrex GPD twin outlet gear pump, maag pump systems has created an absolute innovation: Two different nozzle blocks can be supplied with an individual and constant melt stream by one extruder. The specific output and die pressure is guaranteed by the design and variable. The operators of extrusion lines can bundle their production capacities and optimise the efficiency of their lines by feeding two separate nozzles with different throughput and pressure demands from a single extruder.

Also part of the system is the CSC 116-RS screen changer with arched cavities. The use of arched screens allows the screen surface area to be enlarged up to 4 times compared with conventional designs. CSC 116-RS also enables operators to keep their production rates at a consistently high level, while at the same time significantly reducing energy consumption and operating costs.

Another exhibit highlight is the PRIMO 200E from automatik pelletizing systems, which is particularly suited to the compounding of thermoplastics and the production of masterbatches up to a line throughput of 1.5 t/h. PRIMO 200E is a single-side mounted dry-cut strand pelletizer with an extra-large cutting width of 200mm. Its unique cutting geometry - with the shortest, unguided length between the feed rollers and cut - permits optimal straight cutting of both hard, abrasive and very soft, flexible plastic strands. The pellet dimensions can be changed very quickly thanks to an optional, automatic pellet length adjustment system. The PRIMO 200E is an absolutely reliable, very robust and sturdy dry-cut strand pelletizer.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login