Theegarten-Pactec is bucking market trends by concentrating its expertise on high-performance machines

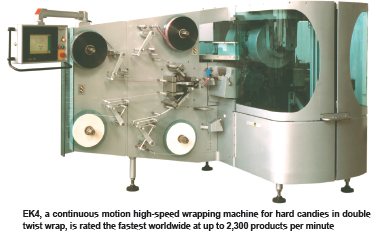

Theegarten-Pactec is bucking market trends by concentrating its expertise on high-performance machinesCONFECTIONERY equipment specialist Theegarten- Pactec GmbH & Co. KG remains unaffected by the economic crisis. A comfortable inflow of new orders in 2009 indicates that the tendency amongst some confectionery producers to postpone new investment projects has not negatively impacted its books. Markus Rustler, co-CEO of the firm, explains why the company's success matrix for small pieced confectionery items lead to another rise in new orders for the first quarter of the current financial year. Mr Rustler, what is it that drives you? My motivation is the ambition to build on something that three generations before me have created over the last 76 years. This means maintaining a sharp competitive edge over our competitors and continuously pushing forward with added value for our customers. How do you envisage your company's market position? We see our role as that of world market leader in our field - by quite a considerable margin. We are more or less the only ones constructing continuous motion high-performance machines for different fields of application. When packaging small pieced articles with double twist wrap such as candies, we achieve output levels of up to 2,300 products per minute. These machines are currently by far and away the fastest on the market. Do you of fer a relatively nar row product portfolio? This may be the initial impression people have, but in actual fact there is no competitor offering such a broad range. Our concept is to offer a product portfolio with something for every type of packaging in every segment. We have almost achieved this level of coverage, and where something is missing, we work to fill the gap. Our low speed range covers output levels of up to 500 products/minute, the medium speed range up to 1,000 products/ minute, and the high-speed range for everything over this. In these different speed ranges, products are categorised in three areas: hard and preformed, which includes boiled candies, cut and wrap, covering articles such as chewing gum or chewy candy, and chocolate. The chocolate sector has developed as a highly interesting market for us: Over the past five years chocolate articles have accounted for between 70 and 75 per cent of our turnover. How high is your export quota? This fluctuates year on year. In 2009 it was just above 90 per cent. This has to do with the location of multinationals such as Nestlé, Wrigley, Cadbury and so on who do not produce in Germany on a large scale. And also, confectionery is produced in practically every country the world over. Did this high export quota entail increase costs for your sales organisation? You may find this hard to believe, but our sales activities around the world are controlled by a team of just four (plus the back office) - which includes myself. This approach is as successful as it is efficient. Of course we also use sales partners in almost every country. We have our own China office in Shanghai, and our Indian partner represents us in India.

Which product do you think best testifies to your leading technological position at the moment? We presented our modular machine concept at the Interpack 2008: The machine models MCC and MCH, which are both based on the same platform. MCC stands for Medium Speed Continuous Motion Chocolate, whilst MCH is the boiled candy variant. This runs at speeds of up to 1,200 products per minute in the double twist wrap range. The same applies to the chocolate version. But both of these also have the capacity to allow other wrapping styles. These machines have been well received by the market, with large numbers already sold. Do you also supply complete lines? Yes, we have a team of around ten working in-house exclusively oNIKE

Which product do you think best testifies to your leading technological position at the moment? We presented our modular machine concept at the Interpack 2008: The machine models MCC and MCH, which are both based on the same platform. MCC stands for Medium Speed Continuous Motion Chocolate, whilst MCH is the boiled candy variant. This runs at speeds of up to 1,200 products per minute in the double twist wrap range. The same applies to the chocolate version. But both of these also have the capacity to allow other wrapping styles. These machines have been well received by the market, with large numbers already sold. Do you also supply complete lines? Yes, we have a team of around ten working in-house exclusively oNIKE

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login