THE nsd tupH corrosion protection treatment introduced by NORD DRIVESYSTEMS is an economical method to significantly extend the lifespan of drive systems with an aluminum casing in applications with aggressive atmospheres, high humidity, or spray water.

Ambit Projects Ltd., a manufacturer of food industry machines, uses nsd tupH protected drives in washers. In King’s Lynn, Ambit designs and manufactures custom equipment for cleaning, processing, and packaging of various food and agricultural products. One of Europe’s leading fresh produce growers and suppliers is a regular Ambit Projects customer. They required a major upgrade and line expansion. The machine in question removes the root and flag of celery stalks and then washes, inspects, and packages them. Given the constantly wet environment and regular washdown with water and foaming agents, the old drives had suffered. Even a high-specification anti-corrosion coating was not enough to provide lasting protection. The paint had split and was threatening to peel. In order to keep debris away from the celery produce, the drives had been outfitted with trays and covers. The drives installed on the belt conveyor in immediate proximity to the washing process were in bad condition. High-pressure jets are used here to remove soil and stones from the produce. The equipment manufacturer was therefore on the lookout for alternative drive solutions that required no extra enclosures.

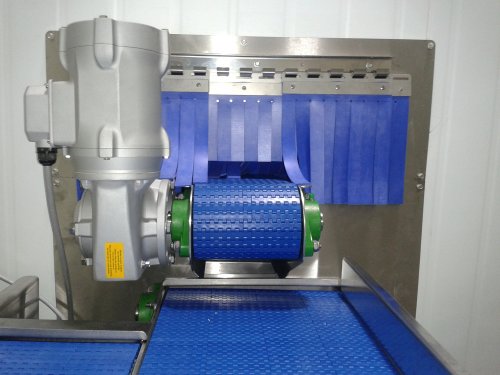

The nsd tupH surface treatment gives aluminum drives a smooth, permanently corrosion-resistant surface ideally suited to process industry applications

(Photo: Ambit Projects Ltd.)

Protection that goes under the skin

NORD Gear Ltd., the English member of the NORD DRIVESYSTEMS Group, told Ambit Projects about a materials engineering innovation – NORD had developed a technology called nsd tupH that fortifies aluminum surfaces by permanently altering the material through an electrochemical process. Instead of applying a protective layer, as is commonly done with anti-corrosion coatings, the aluminum material itself is thoroughly hardened. A great number of NORD drives treated in this way already have a proven track record going back several years. Before the technology was deployed, systems using nsd tupH were tested for resilience against blistering per ASTM D714, corrosion per ASTM D610-08, scribe per ASTM D1654-08 according to DIN EN ISO 2409, salt spray per ASTM B117-09 according to DIN EN ISO 9227, and chipping per ASTM D3170 (Gravelometer test). In many industrial environments, scratches or blows to the drives are to be expected. Under such conditions, even high-quality anti-corrosion coatings cannot reliably provide effective protection. Once the surface layer has been damaged, corrosion easily spreads to adjoining areas. Even rework will not undo the damage for good. nsd tupH is immune to this potential problem. Gravelometer testing showed absolutely no loss of adhesion or chipping. High process safety is therefore ensured. The treatment is approved for food applications according to FDA Title 21 CFR 175.300. It also makes the drives resistant to cleaning agents in the pH2 to pH12 range. Notably, nsd tupH is perfectly suitable for use in marine environments: the salt spray test produced no corrosion even after 2,000 hours. NORD supplies a range of geared motors and mechatronic drives with IP66/IP69K ingress protection. Cleaning with high-pressure steam jets is therefore not a problem. Due to their excellent thermal properties, the aluminum systems can be washed down without cooling down first from the regular operating temperature.

Freshly harvested celery is automatically cut, cleaned, and packaged in a continuous operation (Photo: Ambit Projects Ltd.)

Made for hygienically demanding applications

Ambit Projects replaced all conveyor drives and the drives in the retrofitted machine sections with new nsd tupH units. These are fitted with stainless steel DIN and standard parts and stainless steel output shafts.

Food-grade oil is used as gear lubricant. Paul Oakley, Sales Director at Ambit Projects says, “NORD nsd tupH drives have provided a real value for money solution in terms of extended protection and trouble-free reliability. This application demonstrates our commitment to working closely with our customers and suppliers with upgrades and capacity expansion initiatives that reflect the latest technology improvements – and we will certainly be using nsd tupH protection in other machines we develop.” The new drives in the celery processing line are based on smooth-surface motors and SMI worm gearboxes. NORD has optimized these components as well as other gearbox types for hygienically demanding applications. Smooth surfaces all around without any dead spaces ensure that dirt cannot easily accumulate and that rinsing liquids run off easily.

Smart solution to drive applications in aggressive atmospheres: nsd tupH can be applied to all components with an aluminum die-cast housing (Photo: NORD DRIVESYSTEMS)

Smart full-scale solutions

The use of aluminum drive systems featuring nsd tupH protection against corrosion and mechanical damage reduces maintenance costs and significantly extends the product life. These drives are perfectly suitable for hygienically sensitive applications in the food industry and many other demanding process applications. nsd tupH is available for all aluminum-enclosed drive components from NORD – four gearbox families, smooth-surface motors, and distributed drive electronics. Drawing on an exceptionally comprehensive modular pinion range, NORD is able to custom-configure each gearbox to precisely match application requirements. Users can choose hollow or solid shafts as well as foot or flange mounting. NORD also offers motor starters and frequency inverters with high protection ratings and with nsd tupH. These allow for distributed installations with minimal wiring effort and provide an economic way to ensure protection and efficiency. Typical applications include conveyors, pumps, mixers, and agitators in harsh environments. The units feature all required communication and sensor interfaces and are capable of internally storing routines. NORD provides plug-and-play solutions for all kinds of industrial application.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login