Material savings, reduced use of energy and higher quality are the central requirements in pipe extrusion. According to the most recent experience of Skoplast in Odolanow Kaczory (Poland) the 3LRK-extrusion head, made to the Lichter principle, opens up new dimensions especially in the area of multilayer pipe extrusion: obvious material savings, increased availability by process security and reduction of energy use, proportional to the savings on raw material. Altogether this means: substantially more pipes can be produced against equal costs.

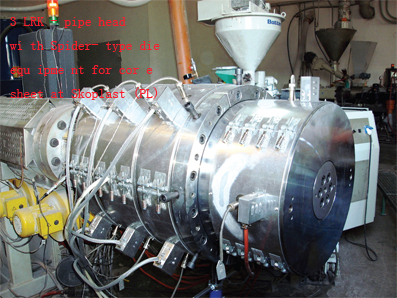

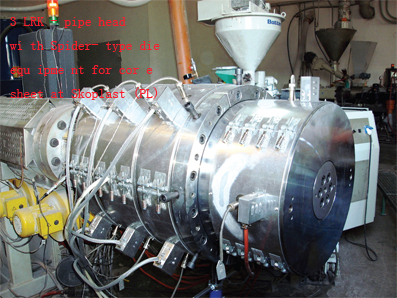

The efficiency increase in the multilayer pipe extrusion is achieved by the perfect match of modern high capacity extruders, the 3LRK-pipe head and downstream equipment that meets the needs. The main scope at Skoplast is the exchange of their present feed block technology that has been used since 2000, with that from Lichter Extrusionstechnik. Krzysztof Szkopek, one of the owners of Skoplast, replaced the pipe head in a co-extrusion system to improve the quality and the profit. For the future this investment means being prepared for the planned change to Pb-free stabilisators. The Lichter head (3LRK-pipe head) is available in three sizes: 3LRK-1 (50-100 mm); 3LRK-2 (100-200 mm); and 3LRK-3 (200-400 mm). For diameters above 400 mm the 3LRK-3 can be used with an extension module. The 3LRK in general is suitable for the production spectrum of smooth multilayer pipes in PVC, PVC-U, PE and PP. Thereby the core layer can be of recyclates, foamed recyclates, new material and foamed new material. The well considered principle of construction enables the operation without extra effort with two co-extruders, without extra effort, if separate colours and/or raw material-types are used. "According to our experience, the use of this Lichter head pays out for all new and replacement investments. Old extrusion lines become more efficient and with new production lines the end result will be improved", says Krzysztof Szkopek. At the same time the total investment for a line with 3LRK-pipe head against a conventional pipe extrusion line with feed blocks is very competitive. Krzysztof Szkopek has been motivated for this investment of the till then far higher use of raw material and the clear improvement of quality: "We find a return on investment of widely within six months realistic." Szkopek chooses the process technical support: support with commissioning and quality insurance is an integral part of the spectrum that Lichter extrusion technique offer Skoplast. The multilayer pipe head 3LRK therefore secures competitiveness of the pipe producer. Optimal melting diffusion To guarantee an optimal melting diffusion the 3LRK-pipe head according to the Lichter principle has been based on a spike die. For PVC and PVC-U this is the almost ideal principle of construction, because the melt flow is delivered by the extruder into a circular shaped flow channel by the extruder. For the core layer, it is transformed by the mandrel directly into a coaxial spine flow. The melt of the outer layer passes through especially geometric formed channels into a relief zone that reduces material deformation and flows eventually to the exit nozzle. Additionally, the 3LRK features a large inner diameter for the material stream. This construction results in a clearly more constant flow of the melt, thin and constant outer layer and dispersing of rheologic and viscosity differences in the layers.

Reduction in density For a model calculation of a SN4-multiple layer pipe (160 mm diameter) Lichter gives an output capacity of 450 kg/h as basic fact. With a total density of 1, 16 g/cm3 an output quantity of 4.476 m/day is achieved with conventional pipe heads (feed blocks). The 3LRK-pipehead allows for a total density of 0, 83 g/cm3 due to its construction and special process measurements - the pipe is base

Air Jordan VII 7 Retro The efficiency increase in the multilayer pipe extrusion is achieved by the perfect match of modern high capacity extruders, the 3LRK-pipe head and downstream equipment that meets the needs. The main scope at Skoplast is the exchange of their present feed block technology that has been used since 2000, with that from Lichter Extrusionstechnik. Krzysztof Szkopek, one of the owners of Skoplast, replaced the pipe head in a co-extrusion system to improve the quality and the profit. For the future this investment means being prepared for the planned change to Pb-free stabilisators. The Lichter head (3LRK-pipe head) is available in three sizes: 3LRK-1 (50-100 mm); 3LRK-2 (100-200 mm); and 3LRK-3 (200-400 mm). For diameters above 400 mm the 3LRK-3 can be used with an extension module. The 3LRK in general is suitable for the production spectrum of smooth multilayer pipes in PVC, PVC-U, PE and PP. Thereby the core layer can be of recyclates, foamed recyclates, new material and foamed new material. The well considered principle of construction enables the operation without extra effort with two co-extruders, without extra effort, if separate colours and/or raw material-types are used. "According to our experience, the use of this Lichter head pays out for all new and replacement investments. Old extrusion lines become more efficient and with new production lines the end result will be improved", says Krzysztof Szkopek. At the same time the total investment for a line with 3LRK-pipe head against a conventional pipe extrusion line with feed blocks is very competitive. Krzysztof Szkopek has been motivated for this investment of the till then far higher use of raw material and the clear improvement of quality: "We find a return on investment of widely within six months realistic." Szkopek chooses the process technical support: support with commissioning and quality insurance is an integral part of the spectrum that Lichter extrusion technique offer Skoplast. The multilayer pipe head 3LRK therefore secures competitiveness of the pipe producer. Optimal melting diffusion To guarantee an optimal melting diffusion the 3LRK-pipe head according to the Lichter principle has been based on a spike die. For PVC and PVC-U this is the almost ideal principle of construction, because the melt flow is delivered by the extruder into a circular shaped flow channel by the extruder. For the core layer, it is transformed by the mandrel directly into a coaxial spine flow. The melt of the outer layer passes through especially geometric formed channels into a relief zone that reduces material deformation and flows eventually to the exit nozzle. Additionally, the 3LRK features a large inner diameter for the material stream. This construction results in a clearly more constant flow of the melt, thin and constant outer layer and dispersing of rheologic and viscosity differences in the layers.

The efficiency increase in the multilayer pipe extrusion is achieved by the perfect match of modern high capacity extruders, the 3LRK-pipe head and downstream equipment that meets the needs. The main scope at Skoplast is the exchange of their present feed block technology that has been used since 2000, with that from Lichter Extrusionstechnik. Krzysztof Szkopek, one of the owners of Skoplast, replaced the pipe head in a co-extrusion system to improve the quality and the profit. For the future this investment means being prepared for the planned change to Pb-free stabilisators. The Lichter head (3LRK-pipe head) is available in three sizes: 3LRK-1 (50-100 mm); 3LRK-2 (100-200 mm); and 3LRK-3 (200-400 mm). For diameters above 400 mm the 3LRK-3 can be used with an extension module. The 3LRK in general is suitable for the production spectrum of smooth multilayer pipes in PVC, PVC-U, PE and PP. Thereby the core layer can be of recyclates, foamed recyclates, new material and foamed new material. The well considered principle of construction enables the operation without extra effort with two co-extruders, without extra effort, if separate colours and/or raw material-types are used. "According to our experience, the use of this Lichter head pays out for all new and replacement investments. Old extrusion lines become more efficient and with new production lines the end result will be improved", says Krzysztof Szkopek. At the same time the total investment for a line with 3LRK-pipe head against a conventional pipe extrusion line with feed blocks is very competitive. Krzysztof Szkopek has been motivated for this investment of the till then far higher use of raw material and the clear improvement of quality: "We find a return on investment of widely within six months realistic." Szkopek chooses the process technical support: support with commissioning and quality insurance is an integral part of the spectrum that Lichter extrusion technique offer Skoplast. The multilayer pipe head 3LRK therefore secures competitiveness of the pipe producer. Optimal melting diffusion To guarantee an optimal melting diffusion the 3LRK-pipe head according to the Lichter principle has been based on a spike die. For PVC and PVC-U this is the almost ideal principle of construction, because the melt flow is delivered by the extruder into a circular shaped flow channel by the extruder. For the core layer, it is transformed by the mandrel directly into a coaxial spine flow. The melt of the outer layer passes through especially geometric formed channels into a relief zone that reduces material deformation and flows eventually to the exit nozzle. Additionally, the 3LRK features a large inner diameter for the material stream. This construction results in a clearly more constant flow of the melt, thin and constant outer layer and dispersing of rheologic and viscosity differences in the layers.  Reduction in density For a model calculation of a SN4-multiple layer pipe (160 mm diameter) Lichter gives an output capacity of 450 kg/h as basic fact. With a total density of 1, 16 g/cm3 an output quantity of 4.476 m/day is achieved with conventional pipe heads (feed blocks). The 3LRK-pipehead allows for a total density of 0, 83 g/cm3 due to its construction and special process measurements - the pipe is baseAir Jordan VII 7 Retro

Reduction in density For a model calculation of a SN4-multiple layer pipe (160 mm diameter) Lichter gives an output capacity of 450 kg/h as basic fact. With a total density of 1, 16 g/cm3 an output quantity of 4.476 m/day is achieved with conventional pipe heads (feed blocks). The 3LRK-pipehead allows for a total density of 0, 83 g/cm3 due to its construction and special process measurements - the pipe is baseAir Jordan VII 7 Retro

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login