The cure time as a main part of the total process of rubber injection moulding is a key factor with significant potential for optimisation. Within the framework of the research project “Cure Time Reduction” at the Montanuniversitaet Leoben, Austria, influencing factors for the injection and heating process were systematically investigated and optimisation strategies were derived. The understanding of flow and thermodynamic processes during the injection phase was considerably improved as part of the experimental investigations.

The FFG-Bridge “Cure Time Reduction“ project was funded by the Austrian Research Promotion Agency (FFG). Industrial project partners were as follows: Erwin Mach Gummitechnik GmbH, Hirm (elastomer processing), Maplan GmbH, Ternitz (elastomer injection moulding machines and engineering solutions) and Semperit technische Produkte GmbH, Wimpassing (elastomer processing).

Project leader Dr. Leonhard Perko created an empirically verified programme to calculate increases in temperature of rubber compounds during the injection moulding process. An additional model enables users to estimate potential cure time reduction even before process optimisation has been carried out. A software assisted cure time reduction ensuring complete cross-linking enables significantly shorter cycles, minimising energy requirements. Additionally, the potential for increasing bulk temperature by means of superposed shear and extensional heating in a conical die was practically recorded and predicted using the programme. Furthermore, compression heating in rubber compounds was scientifically investigated for the first time within the framework of this project.

Calculation model for superposed shear and extensional heating in conical dies

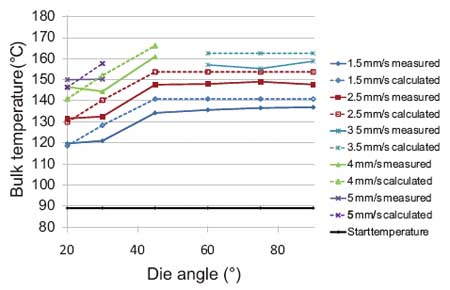

The basis for observations of shear and extensional heating in conical dies are the analytical models developed by Cogswell and Binding. For practical verification, the flow field in the inlet area of the die was investigated experimentally. The investigations showed that die angles of >45° resulted in “dead areas” with almost no material flow. The bulk temperature measurements downstream of each conical die were used to verify the calculation model. Figure 1 shows the measured temperature increase as a function of the die angle for differing injection speeds (continuous lines). The intermittent lines show values derived using the new Perko calculation model.

Figure 1: Melt temperature as a function of die angle: comparison of measured and calculated values (NBR test compound)

The maximum temperature increase achieved was 70℃. An interdependency of the bulk temperature and die angle was witnessed in a range of 20° to 45℃. A further increase in die angle had no additional effect.

Investigation of cure time reduction by means of conical dies

The combined shear and extensional heating in conical dies could be described by means of a new calculation model, as already mentioned. Using an experimental mould, injection moulding experiments were carried out under different process conditions. The parts produced were tested as follows: a) hardness, b) compression set and c) tensile test. Above all, the compression set in the middle of the injection moulded parts proved to be a good indicator for the critical cross-linking of parts.

The practical experiments showed that the injection work is the main influencing factor on the temperature increase of the rubber compound also having a major influence on the curing time. Further optimisation of the conical die geometries resulted in no additional technological improvements.

Cure time reduction by means of compression heating

In addition, the potential of compression heating in rubber compounds for the reduction of heating times was investigated. The measured values for the compression heating induced by pressure increase of 1,800 bars were 10℃. The systematic deployment of a compression phase in the cycle however did not lead to any noticeable improvements in part quality or cure time reduction. Conclusion: compression heating is not suitable for cure time reduction. The reasons are the relatively small temperature increase attained (approx. 10℃ at 1,800 bar pressure increase) and the fact that the vast majority of the generated heat is lost through the cooler walls of the injection unit.

Cure time calculator

Investigations of the calculated potential for cure time reduction depending on the thickness of the moulded part were carried out. The experiments showed that the heating time of moulded parts with a thickness of less than 4 mm could hardly be reduced at all. The potential grows with rising mould temperature TW and increasing part thickness. Project leader Dr. Leonard Perko: “The cure time calculator is a new programme that can be used for valid estimates of the possible cure time reduction. Manufacturers of elastomer parts can now systematically optimise their processes as well as mould and die concepts”. The cure time calculator has been made available to rubber processing companies by the project partners.

The practical experiments showed that the injection work is the main influencing factor on the temperature increase of the rubber compound also having a major influence on the curing time. Further optimisation of the conical die geometries resulted in no additional technological improvements.

Additional findings

In the empirical analysis, new findings in five areas of practical significance for processing elastomers were made:

◆Temperature correction of shear viscosity measurements in the capillary rheometer

As part of the project, a new method for correction of shear and extensional heating for measuring improved viscosity data was developed, validated and applied to the viscosity data used within the project.

◆New method to measure elongational viscosity

Elongational viscosity was investigated in order to understand elongation flow occurring in wherever the flow cross-section is changed in parts being injection moulded. The calculation model results in a higher transparency of the process involved.

◆Method to visualise inlet flow

The visualisation of inlet flows improved the accuracy of predicting temperature increases. These experimentally based findings are beneficial for the future design of dies and runners.

◆Programme for the prediction of cure time and the potential for cure time reduction

A calculation programme for the prediction of cure time (cure time calculator) for simple elastomer parts was developed. This enables predictions of the cross-linking density in individual parts as well as estimations of required curing time.

Results and outlook

In order to reach the objectives set, a calculation model was first developed based on current literature, which estimates the flow in conical nozzles and the associated superimposed shear and extensional heating. In parallel, measurements of the relevant material data were carried out with the purpose of achieving an improvement in methods for shear and elongational viscosity measurement in capillary rheometers.

The verification of the calculation of bulk temperature was carried out on a rubber injection moulding machine of the type Maplan MTF750/160 edition. Furthermore, the compression heating in rubber compounds was characterised. The measurements of compression heating correlated with calculation results using the Joule-Thompson equation. Based on these findings, an appropriate process for manufacturing moulded parts with compression heating was developed and tested in practice.

For elongational heating, a prototype mould was developed and used in practical tests on a Maplan rubber injection moulding machine. Here, many findings relevant for rubber processing were gathered regarding the injection process. However, the tests revealed that the cure time reduction is completely dependent on the injection work deployed. The die geometry is not a significant factor as long as it delivers the necessary flow resistance. For this reason, a complex optimisation of the geometry of conical dies was abandoned to save the resources for a significant improvement of the calculation model for the determination of bulk temperature (taking into account axial, radial and tangential components of velocity of the inlet flow).

Jordan ULTRA.FLY

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login