Plastics used in electrical and electronic (E/E) applications are taking a new turn for the better. In this sector, high heat resistance, wall thickness reduction and flame retardance are amongst the considerations of manufacturers who are always on the lookout for new compounds. Polyamide has gained acceptance as the material is ideal for electrical insulation, even as it is resistant to corrosion and high temperature. As a result, many of today’s developments in polyamide properties are directed toward the production of customised compounds for specific electrical products manufacturers’ requirements.

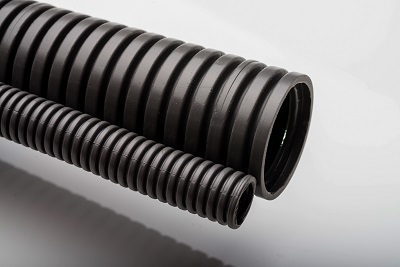

Take the case of the recently-launched polyamide 12 Vestamid® grade from Evonik Industries, which meets the requirements of hazard level 3 (HL3) of the standard EN 45545-2 : 2013 for railway vehicles, which has the most stringent requirements for fire protection. The new, black-coloured moulding compound for cables and cable conduits can be used in sensitive interiors and also in exterior areas.

The new norm EN 45545-2 : 2013 has been in existence in Europe since August 2013 and prescribes requirements for the fire performance of materials and components used in rail vehicles. It places substantially more stringent requirements on the smoke density and oxygen index, a combination which the plastics used up until now were not able to fulfil. Evonik therefore developed the Vestamid moulding compound based on polyamide 12, which meets the required values for both properties. The smoke toxicity also meets the requirements of the new norm.

The newly developed moulding compound has a high dynamic load capacity and high impact strength, even in cold weather, as is typical of Vestamid moulding compounds. Although it is coloured in black, the colouring does not adversely affect the excellent fire-protection properties. Aside from rail vehicles, the extrusion moulding compound can be used in all areas that require high levels of fire protection.

Vestamid from Evonik has a high dynamic load capacity and high impact strength.

High temperature resistant

DSM recently launched its next generation of Diablo high temperature resistant polyamides at the 2014 Fakuma trade show. The new grades are part of both DSM’s Stanyl® polyamide 46 and Akulon® 6/66 portfolios and are aimed at applications in automotive engine compartments where temperatures can reach as high as 260°C.

The automotive industry’s constant drive to create more fuel-efficient designs has resulted in reduced space and higher temperatures under the hood, due in part to the inclusion of such new features as improved pedestrian impact protection and the increasing use of turbochargers and superchargers. DSM’s next generation Diablo grades help manufacturers in this innovation challenge by providing unprecedented heat resistance, both long-term and short term.

The technology provides a significant improvement in long-term temperature resistance components such as air intake manifolds with integrated intercoolers, ducts, charge air cooler end caps, mixing tubes and resonators used in the latest car engines. The latest version of Stanyl Diablo polyamide 46 is able to withstand a continuous use temperature of 230°C, and the new Akulon Diablo withstands a 220°C continuous-use temperature. Both new grades have improved resistance to short-term high temperature peaks as measured by deflection temperature under load (HDT). The new Stanyl Diablo has an improved HDT of 267°C, whilst the new Akulon Diablo has an HDT of 245°C. The long-term heat ageing and the HDT of the new materials are evidence of their superior characteristics compared to competing materials currently on the market.

Air Max 90 Woven

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login