JIMCO A/S

Jimco A/S from Denmark will be presenting their FLO-D® and FLO-K® systems. The newly patented FLO-D® system enables automatic and chemical-free disinfection of surfaces and entire production areas in the food industry.

“The growing focus on food safety in the Middle East means our solutions are very relevant to many customers in the region, and we are very pleased to offer this product to our customers in the region,” says Jimmy K. Larsen.

FLO-K® is an air purification system which purifies the air from organic grease and oil and eliminates odour from processes. Both systems use a process called photolytic oxidation, whereby the contaminated air or surface is subjected to a combination of UV-C light and ozone. This results in the contaminants being oxidised or cold incinerated.

GERSTENBERG SERVICES

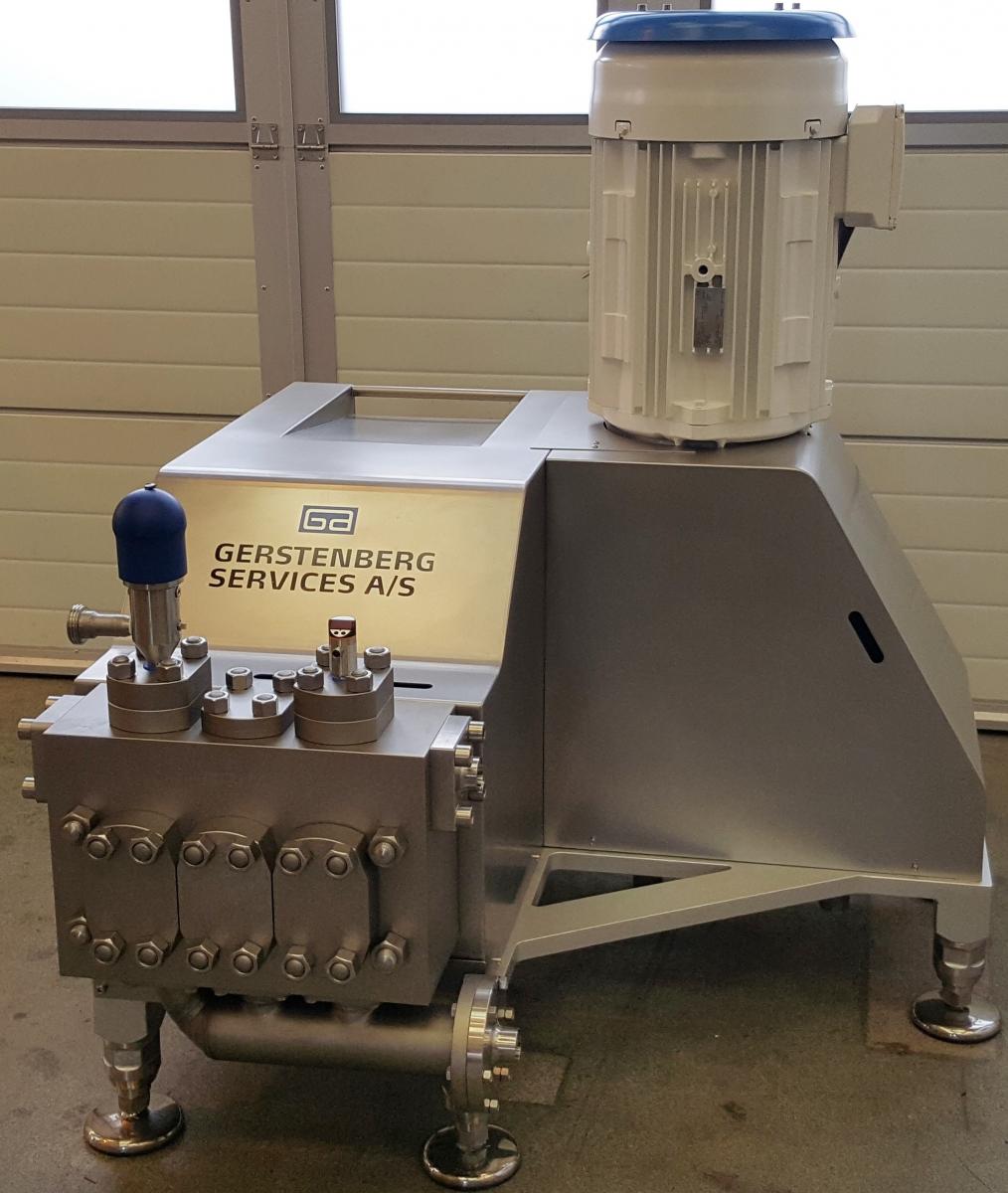

Hygiene and serviceability have been central to the design of Danish manufacturer Gerstenberg Services' new Polaron pump.

"The new pump is designed to allow for the vital parts to be serviced and changed easily with a limited amount of dismantling required. This means less down time in relation to services as well as a reduction in the number of hours required to maintain the pump," says Managing Director Jesper Andersen.

The design also ensures that the pump can be cleaned and sterilised easily using CIP.

Hygiene and serviceability are guiding principles in the design of Gerstenberg Services’ new Polaron pump

Furthermore, it addresses the increased market demands for food safety and hygienic design and complies with the 3-A Sanitary Standards, with all product-contacting parts made in AISI 316 or better.

The pump is intended to work with the Gerstenberg Polaron SSHE or to replace older high pressure pumps in existing production lines. The pump is designed for a working pressure of up to 120 bar depending on product and capacity.

JEROS

JEROS is experiencing first-hand the region’s growing demand for equipment that saves time in production while ensuring high food safety standards are met.

“As the industry grows, so does the demand for systems that enable a more efficient and secure production. This is driven not least by large food manufacturers who are establishing themselves in the region, putting food safety very high on the agenda,” says Evita Rosdahl, CEO of JEROS.

Effective cleaning to a high standard

The Danish manufacturer of washers has seen an increased interest in its products in the region. Among recent orders is a washing system for National Food Industries LLC in Dubai. Here, JEROS’ washers ensure that weighers and scales are cleaned effectively, limiting the wash time and speeding up production changes.

“The Middle East has high food safety standards, meaning that equipment has to be washed frequently. A multi weighing scale, for example, has several scale pans that needs to be washed separately. These scale pans are expensive, and it takes a lot of time if employees have to wash them manually,” Evita Rosdahl explains.

JEROS’ products save food manufacturers time while ensuring each piece of equipment is cleaned thoroughly. The employees use trolleys so that they do not have to fill the washers by hand

HSA SYSTEMS

A newly developed ink and ink delivery system from HSA Systems of Denmark provides food manufacturers with a new way to ensure the durability and precision of printed food marking while keeping costs low.

Food manufacturers can now obtain a permanent result with Thermal Inkjet (TIJ) printers on non-porous materials like plastics, films and foils. Previously, more expensive Continuous Inkjet (CIJ) technology had to be employed.

“The ever-increasing demands for traceability of food products means food manufacturers need an efficient and reliable system that qualifies for camera verification, is water- and lightfast, which doesn’t smear and which dries quickly on the surface. Previously, this has only been possible on non-porous materials by using CIJ printers,” says Partner & Manager Jesper Hyldager.

HSA Systems’ solutions, including the new solvent ink, help improve traceability in the food industry

Lower cost and improved durability

The new ink delivery system and ink address the issue, saving food manufacturers investments and maintenance costs.

“The new HSAJET® K4032 Black Solvent Ink creates a durable high contrast and clear print kept perfectly intact throughout the lifetime of the product,” says Jesper Hyldager.

HSA Systems’ printers can print product information directly on the food packaging or on the outer packaging. Using the company’s software and printers, the food manufacturer can easily create and print variable data, including 1D and 2D codes, best before dates and lot numbers.

HSA Systems offers ink for practically all types of material, including cardboard, coated cartons, plastics, blister foils, metal lids, foils and wraps – materials that are all used in the food industry.

The Pavilion of Denmark will be located in Za’abeel Hall, stand Z2 – D14. Other Danish companies participating at this event are:

· A/S Dybvad Stålindustri

· Detectronic A/S

· LINCO Food Systems A/S

Nike Mercurial Superfly

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login