IN LINE with manufacturing capacity expansion efforts, Dealercast has recently installed a second Unison all-electric CNC tube bending machine at its Manchester plant.

The 50mm Unison machine is expected to boost the company's all-electric servomotor-controlled bending capability, which is cost-effective for small-batch production runs. The addition of the second machine also increases the tubular sizes that can be manipulated.

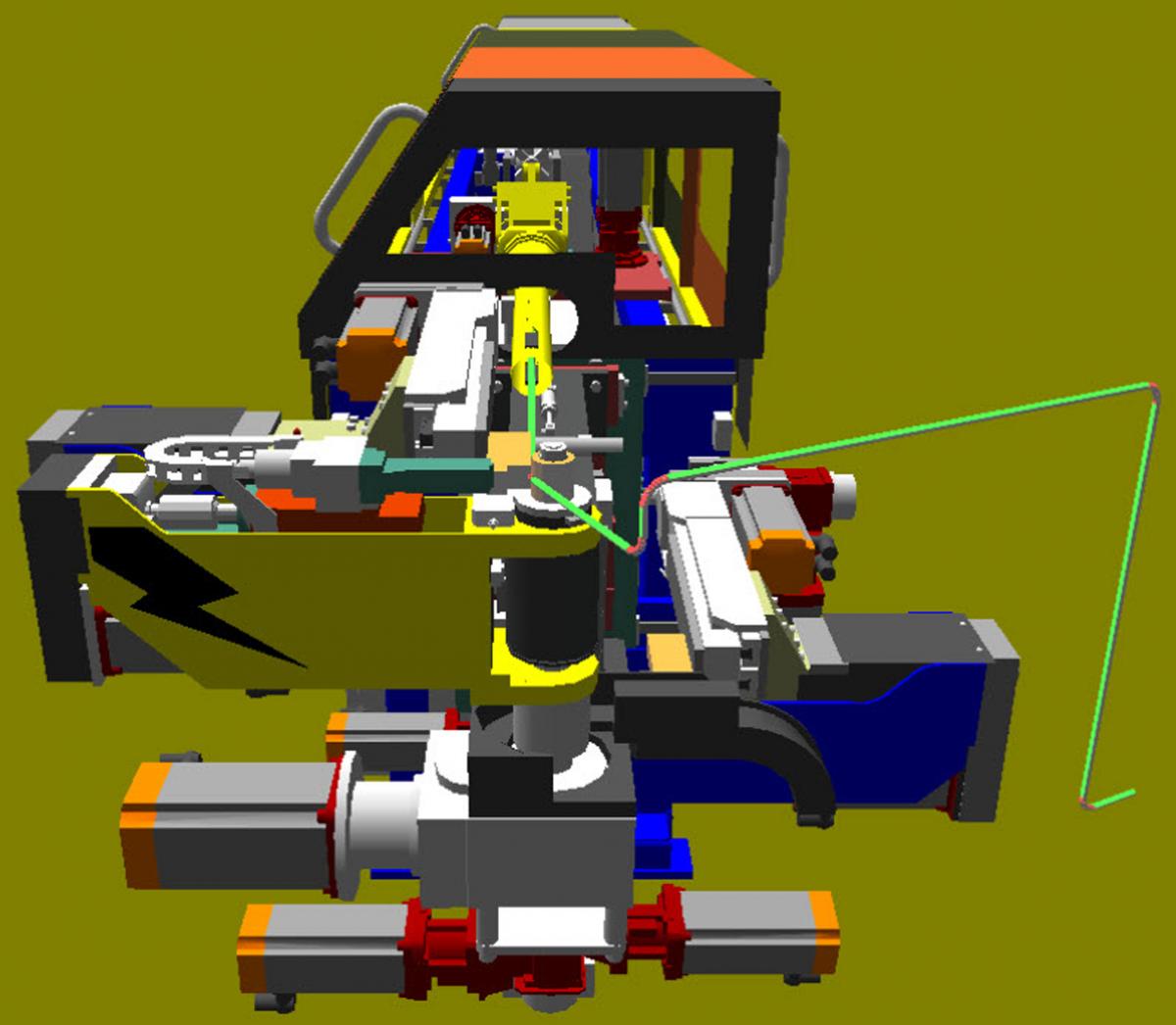

This Unison 50mm all-electric Breeze tube bender has enabled Dealercast to expand manufacturing capacity at its Manchester plant

Managing director Michael Lythgoe said the company sought a machine that would provide reliable long term performance and a reasonable return on investment without compromising high residual value.

Dealercast already uses a Unison 40mm Breeze all-electric machine for the bulk of its tube manipulation work. It also has older hydraulic tube benders and hydraulic roll-forming machines for producing tubes or sections with large diameter curves.

The company likewise ordered Unison’s Unibend Office software package in efforts to optimize workflow and create a more efficient manufacturing environment. The software can be used on a standard desktop PC in isolation from the bending machine. It will allow Dealercast to create bend programs for its existing 40mm tube bender and the new 50mm machine. It also works with Unison’s powerful Opt2Sim machine 3D simulation software, enabling Dealercast to fully test and optimize programs before downloading them to the bending machines, which translates to machine time savings.

Unison’s powerful Opt2Sim 3D machine simulation software allows programs to be tested and optimized before they are downloaded to a bending machine

“We are increasing our production capacity—and our manufacturing flexibility—to stay ahead of our clients' needs. Unison’s tube benders fit these requirements precisely,” Mr. Lythgoe said.

A leading UK manufacturer of grab poles for public transport vehicles, Dealercast operates an ISO 9001-compliant tube bending and fabrication shop for the manufacture of one-off prototypes to volume production of parts in large batch sizes. Its purpose-built factory can handle tube manipulation, fabrication, casting, and CNC machining. The company leverages expertise in the manufacture of tubular grab poles and handrails for architectural applications and public transport vehicles to serve clients in the bus, coach, and railway vehicle manufacturing sector.

Men's Sneaker Hub Online

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login