The Frigel Group has brought many innovative developments to its process cooling solutions for the plastics industry. Its entire product lines now include a full digital control technology plus many upgrades in almost all of its product categories. In an interview with International Plastics News for Asia, Mr. Emanuele Barbagli, Chief Operating Officer (COO) of Frigel Asia Pacific Co., Ltd., provides an update on Frigel’s recent product developments and how these benefit plastics processors in these challenging times.

What are the recent product developments introduced by Frigel?

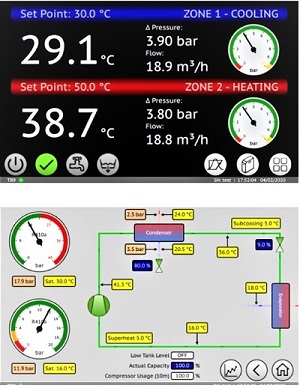

Mr. Barbagli: Frigel has introduced many innovative solutions to our portfolio for plastic processors to achieve intelligent process cooling and save on production costs. Some of these are new products while others are upgrade of existing models. At the K 2019 exhibition, Frigel showed off an upgrade of the Ecodry Adiabatic Fluid Cooler, Frigel’s most proven adiabatic cooling technology in the market today with its 95% water savings. Another product is Microgel™ TCUs with Booster Pumps and Integrated Portable Chiller where Frigel offers in traditional ranges for Injection Moulding (RCM/D Series) – single and dual zone, for moulding throughputs from 10 to 900 kg/hr (20 to 2000 lb/hr) and Microgel for Packaging (RCP Series) – from 100 to 2000 kg/hr (220 to 4400 lb/hr), now both with 100% new digital technology and touch screen control.

Mr. Emanuele Barbagli, COO, Frigel Asia Pacific Co., Ltd.

There’s also the new line of Mould Temperature Control Units for every possible application – four completely new lines of Thermogel, the TBD Series which offers a robust and cost effective solution for general moulding applications; TDK Series and TPK Series pressurized water TCUs for high temperature applications, developed and designed in partnership with Matsui. The new Thermogel Heat&Cool THC Series process synchronized alternating heating and cooling units are designed specifically for high quality surface finishing of moulded part, while the Turbogel range TGM/D Series is a unique TCU featuring powerful booster pumps and high performance cooling capacity and intended for cycle time reduction in high throughput moulding applications.

We also have two new lines of chillers. The IndustrialChiller – Air Cooled MRM Series – includes a full range of heavy-duty modular chillers from 90 to 580 kW (25.6 to 165 tonnes). Another is the ModularChiller – Water Cooled 3FX Series which are unique chillers combining high performance cooling capacity with unbeatable efficiency in self-contained packages with extremely small footprints. Frigel also offers two completely new products, CapCooler–CAP Series, post-moulding closure cooling units for ultra-fast moulding cycles, and the MoldDryer–MDE Series, air dehumidifiers for mould enclosures to avoid sweating in low cooling water temperature applications.

Can you please explain how MiND works and how would this impact the operations of your customers?

Mr. Barbagli: MiND is an extraordinary product and the benefits are many. Since we introduced this innovative tool to our customers, we have seen a big impact in their productions as they are now able to measure the efficiency and operational consumption of their systems.

Thanks to the data gathered by MiND, our customers can easily identify inefficiencies in their cooling process and make the adjustments or adaptions for maximising performance and minimising consumption. This is possible via a web-based interface designed for customers that gives them the possibility to access to MiND and see their Frigel equipment and non-Frigel equipment where communication is possible, any time from any computer in the building or remotely. We all know that familiarity with your own process and how it performs day by day is nowadays key to successful operation. Indeed, we have seen customers in Asia that could make big change in their outcome after MiND was implemented as they finally had a better understanding of what is going on in their factories.

Our customers have also seen a significant reduction in the unplanned downtime in production as MiND offers both the possibility to monitor the systems and access to settings of the Frigel machines. By monitoring the behaviour of the systems we have seen that both the customers and Frigel personnel can identify in advance and correct anomalies or changes in the process that could lead to failures. While accessing the historical data and the settings of Frigel machines in real time, we are now able to resolve problems and tune the systems remotely in almost no time.

Especially in these challenging days when traveling is not allowed and social distancing is mandatory, MiND serves as the key element to continue supporting our customers on new installations and troubleshooting like we were there with them, and in making sure that their production can start or continue smoothly as always.

In the wake of the coronavirus outbreak, how did Frigel ensure that there is no break in the supply chain, especially in providing needed parts and services to your customers around Asia?

Mr. Barbagli: Here in Frigel Asia Pacific, we actually have been able to deal with this challenge without too much efforts. Two factors made this possible. First is that at Frigel Asia Pacific, we manufacture the majority of the products that we sell in Asia, and so we usually manage quite a big inventory of materials that this time worked as a buffer. Secondly, after we saw that the virus severely hit Italy, we knew that it would have spread throughout Europe and we decided that we needed to have a contingency plan to ensure that we continue production for the next 8 to 12 weeks even in case some of our main suppliers would have been forced to close due to the lockdown in their countries.

Bearing in mind the worst case scenario, we worked to increase our stock in advance where crucial and possible and where this was not viable, we started looking for alternative supplier in other countries not yet hit by the virus. This worked quite well even if at the end, fortunately, most of our suppliers stayed open or had a very short shutdown that somehow didn’t affect our production. But if it did, we would have had some alternatives ready that would be useful in the future.

Speaking of people and support to our customers, I am quite satisfied with what we could accomplish so far considering that we are not allowed to travel overseas. In countries with no lockdown, we have been able to provide full support with the presence of our local people otherwise we could do everything from remote, thanks to the new products developed in the past years like MiND and others. In Thailand, Frigel has continued assisting our customers as usual when needed and of course where complete safety of our people is guaranteed.

What measures did Frigel implement to ensure the safety of its operations and staff during the pandemic in Asia?

Mr. Barbagli: As the safety of people always comes first at Frigel, we had no doubt that introducing immediately stricter measures would have been the winning solution, in doing so, we ensured the health of our staff as they work in the plant and guaranteed the continuity of our production and remote support to our customers.

I have to say that the first wave of this virus did not really have an impact on our plant but as soon as the outbreak hit Italy and we saw that the virus was already spreading throughout Europe, we immediately understood that it was just a matter of time before it would have reached Thailand and Southeast Asia, and this time with a much bigger impact! So our first step was to create a team in Frigel Asia Pacific for centralised communication that meets regularly, monitors closely the situation as it continues to evolve, informs employees of the new directives and rules, and supports our staff on a daily basis during this tough period.

As said, we decided to implement immediately severe measures very similar to our headquarters in Italy even if at that time here in Thailand, the infection was not yet as widespread. These measures include a reduction of visits to our plant, daily measure of the body temperature of all the people, intensified the sanitization of the work place, provided all essential products like gel sanitizer and face masks to the staff, and organised all the activities in the building for maintaining the minimum recommended distance among the people. To do the latter, we decided to let some departments work remotely from home. We did this in advance because there was still too much unknown about this virus and also because we knew that people would have needed some time to get familiar with these new rules and behaviours. As for our people that were overseas working on projects, we managed to get them back home safely before lockdowns in those countries, like in the Philippines.

We see now that the measures undertaken were successful as the outbreak had no impact at all on our productivity, both in terms of manufacturing and effectiveness of support to our customers.

Frigel Asia Pacific Co., Ltd.

Tel: +66 38577799

E-mail: sales.fap@frigel.com

Website: www.frigel.com

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login