KEY TECHNOLOGY will share its latest sorting platform to processors of fresh, frozen and dried produce at Fruit Logistica from 3-5 February 2016.

The company’s VERYX™ digital sorting platform carries the latest capabilities, including those that fruit and vegetable processors consider tough. According to the company, this suite of sorters works for fruits and vegetables, as well as processed potato products, nuts and the like.

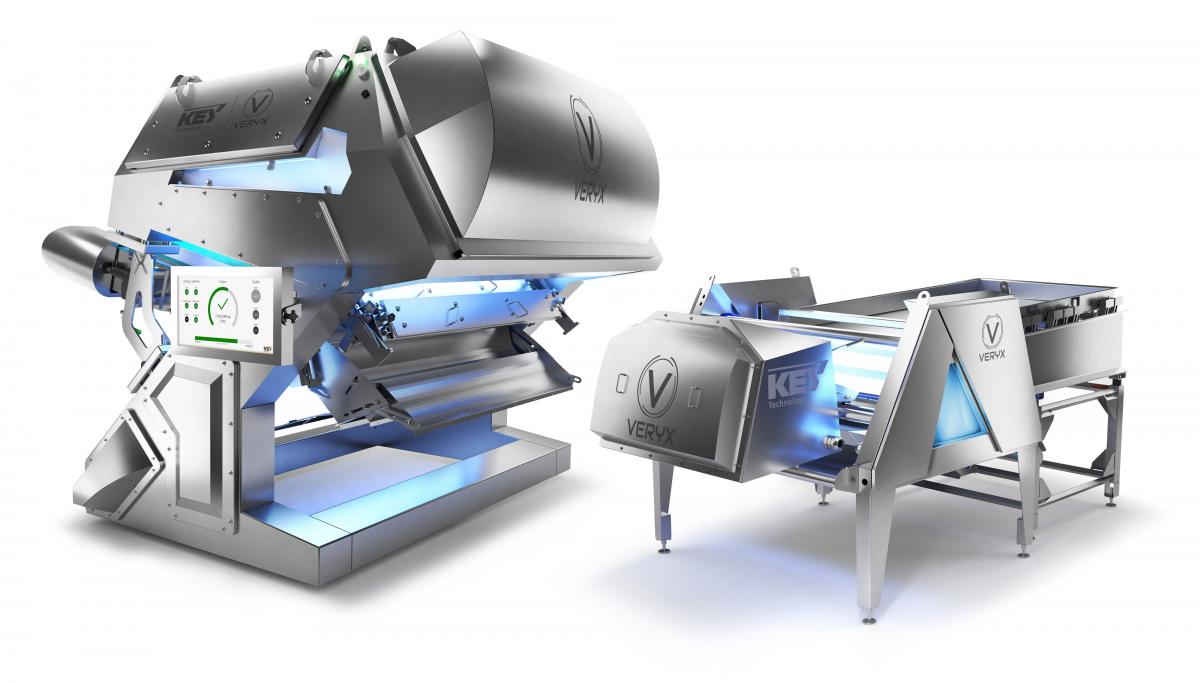

Consisting of belt-fed and chute-fed sorters, it employs a common user interface, boasts all-sided surface inspection multi-sensor Pixel Fusion™ and the highest resolution cameras and laser sensors available on a digital sorter. These features allow sharper detection of foreign material and product defects.

The company claims the VERYX™ is the world’s most intelligent platform, and with advanced auto-learn, self-adjusting capabilities and recipe-driven operation, operation is also a cinch.

“The platform will include widths ranging from 700mm to 2100mm for belt-fed and 700mm to 1400mm for chute-fed configurations and combines a highly innovative new mechanical architecture with intelligent decision making to maintain optimal performance through the entire production cycle. VERYX minimizes the need for operator interaction with the machine and establishes new standards of performance to offer exceptional customer value.” said Louis Vintro, Senior Vice President New Products & Business Development. “VERYX complements our existing family of digital sorting systems allowing us to choose the optimal sorting solution for our customers’ specific needs.”

The sorters are configured based on the product characteristics, application requirements and process objectives of each customer, and they can be used for small to large production capacities. The belt-fed sorters chute sorters are fed by the company’s own patented Chycane® chute system.

Managing blind spots

Blind spots can be dealt with by configuring the sorters with sensor arrangements. On belt-fed systems, the bottom cameras are positioned away from product splatter to ensure the lower sensor windows are not obstructed by buildup over time. Eliminating this previously common performance degradation factor keeps bottom cameras continually operating at peak performance and makes VERYX the first sorter to offer sustained 100 percent surface inspection throughout the production cycle.

Multi-sensor fusion at pixel level

No existing sorter has the multi-sensor fusion at the pixel level. This is an advanced feature that integrates the input from multiple cameras and lasers in relation to each image pixel. Fusing sensor data at a pixel level maximizes the signal contrast for enhanced differentiation between good and bad objects to more accurately identify and remove subtle product defects and challenging FM types.

Next-generation cameras and laser sensors offer twice the resolution capability of previous generation sorters to detect and remove the smallest defects and FM. With up to 4 channels of information from cameras and up to 8 channels of information from the laser scanner, combined with advanced LED lighting that operates at optimal frequencies in relation to each sensor, Key customizes every VERYX sorter to perfectly match the customer’s requirements, from basic to the most complex. The new product separation / ejection system is also tailored to each product application, with the distance between nozzles and the power of the valves varying for optimal management of the sort streams.

The modular design of the VERYX enables food processors to easily upgrade their sorter in the field with the addition of more or different cameras, lasers or BioPrint™ hyperspectral sensor technology, as customer requirements evolve over time.

Leveraging richer product information and Key’s powerful new data processing architecture and intelligent software, VERYX can make new and more robust sorting decisions while easing use. Smart features such as auto-learning, self-adjustment algorithms, predictive system diagnostics, smart alarms, FMAlert™ and Sort-to-Grade™ will enable VERYX to operate virtually unattended during normal production. Operator qualification requirements are reduced, making it much faster and easier for a new operator to become a proficient user of the equipment compared to other sorters.

VERYX has an intuitive user interface (UI) that can provide different views to users of various levels, depending on their needs. Recipe-driven operation ensures customers can count on consistent performance from their VERYX sorter day in, day out, including running the same product across multiple sorters in different lines or locations. The streamlined UI enables the sorter to run a different product or grade at the touch of a button.

The new platform also adopts the Key’s Information Analytics, a set of data acquisition and connectivity capabilities that allow users to gather a broad range of product and operational data from the sorter. The data can be made available for off-line analysis or connected to a customer’s SCADA or Manufacturing Execution System.

VERYX sorters leverage Key’s specialized material handling solutions to optimally convey and control each object through the sort process. This ensures ultimate accuracy in sorting out every piece of FM and defective product, avoiding the inadvertent removal of good product in the process.

In addition to being easy to use, the new platform is also easy to clean and maintain.

Visit the company at Hall 7.1B, Booth N° A-03.

Related reports:

Gravity-fed sorter for dates

Why Chappellet opted for the VitiSort

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login