CONVECTION drying is gaining momentum as the technology of choice for fragile products such as potatoes. Its ability to remove surface moisture and maintain product consistency makes it an ideal method for industrial potato drying, commonly applied in French fries, dehydro-frozen potatoes and dehydrated products.

Convection drying technology uses hot air for heat and mass transfer. It applies an alternating airflow direction, which results in faster surface moisture dissipation without the risk of degrading product consistency and quality.

In preparing potatoes for French fries, conveyor drying is employed prior to frying to raise solid content. This method enhances fryer efficiency whilst lowering oil consumption. Drying also concentrates flavours and completes the gelatinisation process started in the blancher. The higher humidity of the recirculated air increases the potato’s core temperature without over-drying the surface. These combined help in achieving an appealing texture for French fries.

Dehydrated potatoes, which are typically used in dry soup mixes and reconstituted dry potato entrees, undergo drying to reduce water activity and inhibit bacteria and mould growth toward extending shelf life. Dehydration also minimises enzyme activity, which breaks down product cellular structure.

French fries, anyone?

Gentle drying at lower temperatures is ideal for drying potatoes for French fries to prevent product sticking and case hardening. A multi-stage conveyor dryer is suitable for this purpose as it allows individual control of process air temperature, humidity, airflow rate and retention time for each stage. For overall weight loss, the common moisture removal targets range from 5% to 20%.

The process, however, is not without its challenges. One has to maintain equal up/down airflow symmetry and zone-to-zone temperature and humidity control to ensure optimum drying efficiency without risking surface texture quality targets. Drying efficiency and high humidity must be sustained whilst still achieving weight loss. The correct transfer point must be selected for each stage to minimise product sticking. The proper metallurgy needs to be selected to correspond to potentially corrosive pre-treatment. Finally, energy efficiency has to be optimised and operating costs reduced.

Dehydro-frozen potatoes and dehydrated products

Dehydro-frozen products, which are used in convenience foods, fresh soups and frozen entrées, are blanched upstream like French fries. But unlike them, the emphasis is on weight loss and flavour concentration, not surface texture so there is less need for precise humidity control and equilibration after drying.

Convection drying, which uses alternating airflow direction, removes surface moisture and maintains product consistency

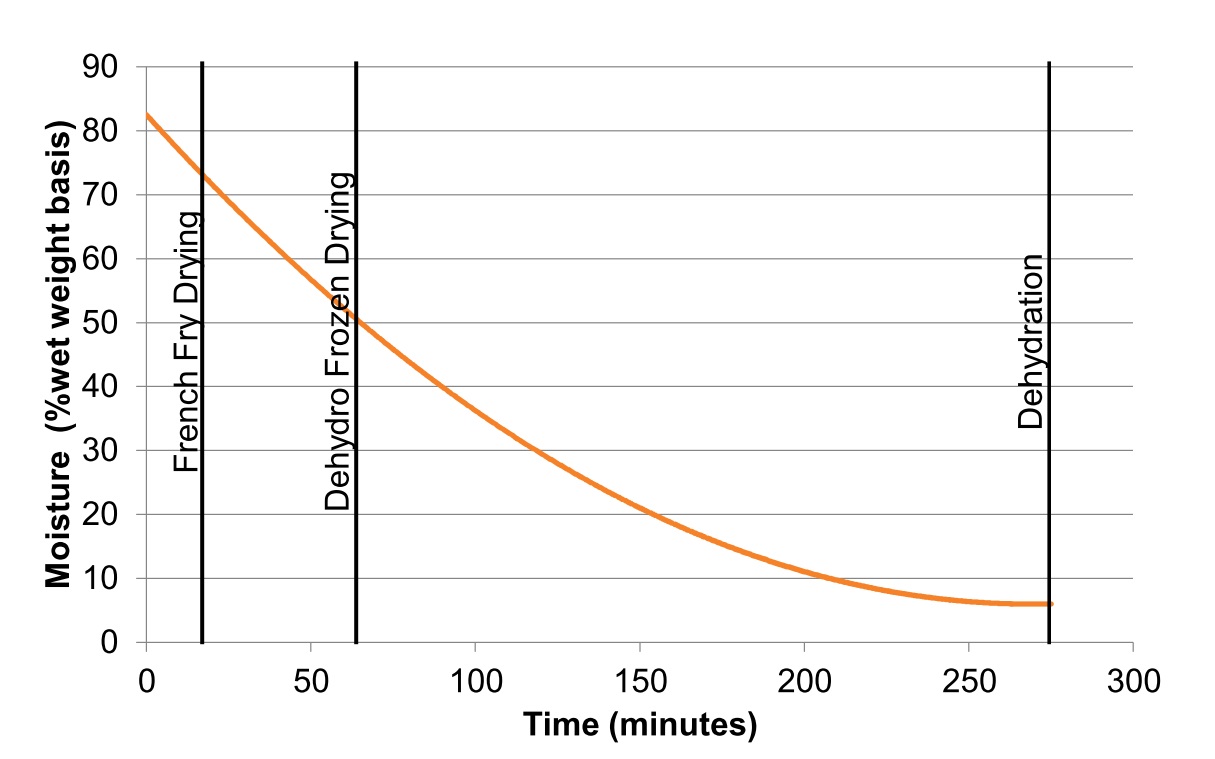

As with French fries, a multi-stage dryer is recommended to achieve moderate through-bed air velocity for high drying efficiency, with the common moisture removal target at about 50%. This allows products to be reoriented at different stages and dried uniformly.

After drying, dehydro-frozen products are cooled and frozen. Low temperature is ideal to maintain product colour and quality, and prevent product sticking.

In dehydrating potato slices, dices and shreds, one has to achieve proper product texture during the upstream blanching process to avoid feeding problems in the dryer. Correct dewatering of flume water is important to prevent sticking. The products must also be loaded evenly, and accurate adjustments in the transfer sections made to avoid degradation. The operating conditions should match the product to prevent discolouration.

Because potatoes carry a surface moisture load from blanching and water flume transport, efficient dewatering is important for a good dryer feed stream. Slower drying is preferred to achieve best quality at lower temperatures and prevent product sticking and discolouration. Moderate through-bed air velocity is needed for high drying efficiency.

A multi-stage dryer achieves as much as 70% to 85% material infeed evaporation during the first stage of a typical load. This keeps product temperature low through evaporative cooling and minimises product sticking.

Product shrinkage results in deeper piling and longer dwell times, whilst slow dehydration maintains colour and taste. To ensure product and evaporation rate are uniform, multiple turnovers are done.

Continuous product feeds yield a common entry and exit moisture of 80% to 82%, which can be dried to 6% moisture content.

Co-product drying for hash-browns

Potato bits and pieces are processed into hash-browns or hash-brown patties using a co-product drying line. The resulting 8% to 12% weight loss increases the solids-to-water ratio and minimises the amount of water entering the downstream fryer.

Cooling involves an integral cooling zone or a convection cooling conveyor. This phase exposes free starch, which aids cohesion and holds newly formed co-products.

Saving energy in the process

Energy efficiency remains a core target. Many conveyor dryers, which consume large amounts of production line energy, operate 30% below potential efficiency. Besides educating processors about energy usage, Bühler Aeroglide helps operators evaluate processes and mechanical functions to improve energy efficiency.

Looking to the future, besides achieving optimum results, companies will ensure the most hygienic cleaning possible and keep downtime to a minimum in response to new and more stringent food safety regulations worldwide. Innovations will revolve around enabling a dryer to handle a variety of products through advanced automation and process control. Food processing validation is likewise expected to gain support. Bühler Aeroglide has introduced a revolutionary hygienic dryer for a variety of food applications, including potato processing.

*Ron Walunas is Applications Engineer at Bühler AeroglideNike Kevin Durant

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login