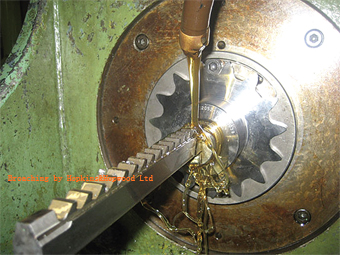

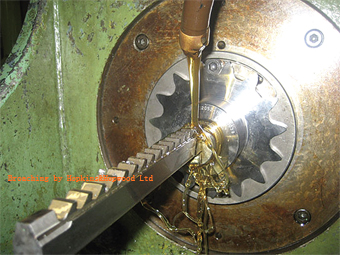

Broaching is the machining process of cutting a shape by moving a broach cutting tool, usually called a broach, over a material, such as metals or plastics. It is the simplest method of cutting internal forms known as splines on gears, sprockets, and hubs. The broach's rows of teeth, or chisels, progressively increase in size. Each tooth removes the excess material gradually and the desired shape is complete only after the final broach tooth has passed through the material. The shape found in an internal keyway in a pulley or gear is the most common shape produced by broaching, since polygons such as squares are also commonly and easily produced by a broach, especially when a round hole needs to be enlarged into a square or other non-circular shape. Sometimes, broaches are also used to cut external shapes, for example slots.

Interestingly, due to the effectiveness of their original concept and design, today's broaching machines and processes have remained mostly the same since the start of the industrial revolution. No job is too large or too small for a broach. Numerous materials both ferrous and nonferrous metals are suitable for broaching. Multiple-point cutting tools Broaching tools fall under the classification of multiple-point cutting tools as they have at least two cutting edges. Broaches can be custom made from blueprints, but stock broaches are often readily available in numerous lengths and sizes. Common broach shapes include square, round, oval, keyway, serration, D, spline, and pot broaches. Typically, broaches are made from top quality tool steel, for instance PM-M4. Besides the broach cutting tool itself, fixtures that support the broach are also needed in broaching operations. For example, in keyway broaching, a fixture called a broach horn supports the broach in a shared circular hole. All broaching operations require proper alignment of the broach and its supportive tooling. Improper alignment will result in cuts that are not perfectly straight. Misalignment can even cause broach breakage. Lubrication is often used in broaching in order to reduce friction, either by applying cutting oil to the material to be cut, or by lubricating the backs of the cutting broaches, depending on the types of broaches and the broaching materials being used. Financing for broaching machines Broaches have sharp chisel points, which allow them to expand smaller holes. The chisel specifications vary from one broach to another. Broaches act as a vital instrument in manufacturing gears, drive shafts or pulleys.

Hand made broaches are very useful, especially for people who work on small scale metal projects. But in large scale engineering work, people have to select suitable machines according to the needs of the projects. Thus, for large scale engineering job you have to opt for those broaching machines that are particularly designed to perform heavy duty work with great precision. These machines have several teeth like structures, which fruitfully make holes in the body of the metals. These types of machines have incredible efficiency added with great accurateness. That's why these machines are so constructive and useful in the metal industry. Having said its usefulness, there is one major problem with these machines in regards to heat. However, the best machines are built in such a way that they reduce the heat and work smoothly without any hindrances. This is the reason broaching machines are so valuable and effective. Vertical and horizontal are the two most basic types broaching machines. There are certain advantages and disadvantages of these two types of broaching machines which are as follows: The advantage with horizontal broaching machine is that it can access any part of the machine. There are integrated adjusting modes in the horizontal machines which obtain differ

Highsnobiety Sneakers Interestingly, due to the effectiveness of their original concept and design, today's broaching machines and processes have remained mostly the same since the start of the industrial revolution. No job is too large or too small for a broach. Numerous materials both ferrous and nonferrous metals are suitable for broaching. Multiple-point cutting tools Broaching tools fall under the classification of multiple-point cutting tools as they have at least two cutting edges. Broaches can be custom made from blueprints, but stock broaches are often readily available in numerous lengths and sizes. Common broach shapes include square, round, oval, keyway, serration, D, spline, and pot broaches. Typically, broaches are made from top quality tool steel, for instance PM-M4. Besides the broach cutting tool itself, fixtures that support the broach are also needed in broaching operations. For example, in keyway broaching, a fixture called a broach horn supports the broach in a shared circular hole. All broaching operations require proper alignment of the broach and its supportive tooling. Improper alignment will result in cuts that are not perfectly straight. Misalignment can even cause broach breakage. Lubrication is often used in broaching in order to reduce friction, either by applying cutting oil to the material to be cut, or by lubricating the backs of the cutting broaches, depending on the types of broaches and the broaching materials being used. Financing for broaching machines Broaches have sharp chisel points, which allow them to expand smaller holes. The chisel specifications vary from one broach to another. Broaches act as a vital instrument in manufacturing gears, drive shafts or pulleys.

Interestingly, due to the effectiveness of their original concept and design, today's broaching machines and processes have remained mostly the same since the start of the industrial revolution. No job is too large or too small for a broach. Numerous materials both ferrous and nonferrous metals are suitable for broaching. Multiple-point cutting tools Broaching tools fall under the classification of multiple-point cutting tools as they have at least two cutting edges. Broaches can be custom made from blueprints, but stock broaches are often readily available in numerous lengths and sizes. Common broach shapes include square, round, oval, keyway, serration, D, spline, and pot broaches. Typically, broaches are made from top quality tool steel, for instance PM-M4. Besides the broach cutting tool itself, fixtures that support the broach are also needed in broaching operations. For example, in keyway broaching, a fixture called a broach horn supports the broach in a shared circular hole. All broaching operations require proper alignment of the broach and its supportive tooling. Improper alignment will result in cuts that are not perfectly straight. Misalignment can even cause broach breakage. Lubrication is often used in broaching in order to reduce friction, either by applying cutting oil to the material to be cut, or by lubricating the backs of the cutting broaches, depending on the types of broaches and the broaching materials being used. Financing for broaching machines Broaches have sharp chisel points, which allow them to expand smaller holes. The chisel specifications vary from one broach to another. Broaches act as a vital instrument in manufacturing gears, drive shafts or pulleys.  Hand made broaches are very useful, especially for people who work on small scale metal projects. But in large scale engineering work, people have to select suitable machines according to the needs of the projects. Thus, for large scale engineering job you have to opt for those broaching machines that are particularly designed to perform heavy duty work with great precision. These machines have several teeth like structures, which fruitfully make holes in the body of the metals. These types of machines have incredible efficiency added with great accurateness. That's why these machines are so constructive and useful in the metal industry. Having said its usefulness, there is one major problem with these machines in regards to heat. However, the best machines are built in such a way that they reduce the heat and work smoothly without any hindrances. This is the reason broaching machines are so valuable and effective. Vertical and horizontal are the two most basic types broaching machines. There are certain advantages and disadvantages of these two types of broaching machines which are as follows: The advantage with horizontal broaching machine is that it can access any part of the machine. There are integrated adjusting modes in the horizontal machines which obtain differHighsnobiety Sneakers

Hand made broaches are very useful, especially for people who work on small scale metal projects. But in large scale engineering work, people have to select suitable machines according to the needs of the projects. Thus, for large scale engineering job you have to opt for those broaching machines that are particularly designed to perform heavy duty work with great precision. These machines have several teeth like structures, which fruitfully make holes in the body of the metals. These types of machines have incredible efficiency added with great accurateness. That's why these machines are so constructive and useful in the metal industry. Having said its usefulness, there is one major problem with these machines in regards to heat. However, the best machines are built in such a way that they reduce the heat and work smoothly without any hindrances. This is the reason broaching machines are so valuable and effective. Vertical and horizontal are the two most basic types broaching machines. There are certain advantages and disadvantages of these two types of broaching machines which are as follows: The advantage with horizontal broaching machine is that it can access any part of the machine. There are integrated adjusting modes in the horizontal machines which obtain differHighsnobiety Sneakers

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login