The wbk Institute for Production Technology at the Institute for Technology (KIT) in Karlsruhe, verified in a recent study the effects of tool mountings on high-performance machining. Different tool mountings had to prove their skill during milling of full and half slots on several machines. The results showed that the SCHUNK TENDO E compact high-performance hydraulic expansion toolholders allow an extension of the service live of up to 300% compared to other clamping systems. That means that up to two third of the tools can be saved.

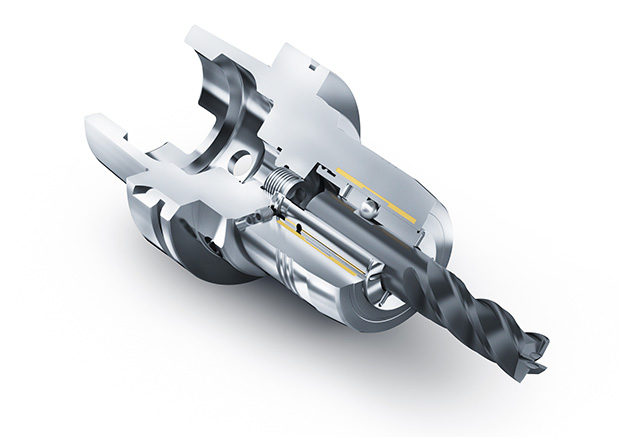

Schunk TENDO AVIATION combines the advantages of the SCHUNK TENDO hydraulic expansion technology and of a Weldon chuck. An integrated anti pull-out locking mechanism avoids slipping out of the tool and damages at the workpiece. Moreover, the cutting data can be partly increased.

Evaluating the test

This study has confirmed Schunk’s own test series by neutral experts for the first time in a comprehensive manner. In the company’s development centre and in customer applications they were repeatedly able to prove that TENDO E compact prevents the cutting edge from damage, that tool life extends, and that chatter marks at the workpiece surface are prevented. Moreover, the text proved that the spindle and the spindle bearing load is significantly lower. The complex interplay of run-out accuracy, rigidity, vibration damping, and of enormous clamping forces contribute to this positive effect. In this connection, the expansion sleeves, and the oil-filled expansion chambers of the TENDO E compact play an important role.

Clamping forces of hydraulic expansion toolholders

Actually, hydraulic expansion toolholders were particularly designed for high-precision drilling and finishing operation for a long period of time. This does not apply for TENDO E compact: clamped in dry conditions, the mounting convinces at Ø 20 mm with a torque of up to 900 Nm. In case of Ø 32 mm, the powerhouse transfers torques up to 2,000 Nm. This is 60% more than conventional hydraulic expansion toolholders achieve. At the same time, it disposes of a precise run-out accuracy of < 0.003 mm at an actual clamping length of 2.5 x D, and a balancing grade (HSK mountings) of G 2.5 at 25.000 rpm. It is suitable for finishing and roughing, and also for drilling, tapping, and reaming. Due to its fast tool change with an Allen key, it is also suitable for flexible machining of small and medium-sized series.

TENDO AVIATION

TENDO AVIATION was particularly designed for demanding precision applications which particularly occur in the aerospace industry, where toolholders with anti-pull-out locking mechanism are mandatory. It has a consistently high run-out accuracy, a balancing grade of G 2.5 at 25.000 rpm, and perfect vibration damping. If Weldon shanks are used, the integrated anti pull-out locking mechanism ensures an orientation of the tool, form-fit clamping, and prevents the tools from slipping out. Moreover, the potentials of tool and machine can be fully used. TENDO AVIATION allows maximum torque transmission at a consistently high precision and process reliability.

Air Max 90 NS GPX

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login