PHILIPPINE Spring Water Resources, Inc. (PSWRI) is one of the first bottlers in the world to be using the Krones Contiform AseptBloc. The company used this state-of-the-art technology for market-launching an aseptically cold-filled and preservative-free iced tea. In 2015, production of the iced tea in lightweight PET container began in a facility in Cebu. One year earlier, the company had already commissioned an ErgoBloc L for bottling water at its plant in Bulacan.

PSWRI entered the water market in 1991 for two reasons. Firstly, there was the personal experience of the founder and current President/Chief Executive Officer Danilo Y. Lua. Due to the quality of the drinking water on his home island of Cebu, with its high calcium content and its correspondingly high level of hardness, he had repeatedly suffered from kidney stones. Because of inadequate hygiene in the drinking water supply, his father had had to undergo frequent treatments for amoebic dysentery. Mr Lua then experimented privately with options for water-softening.

The second reason was a massive natural disaster: in 1990, the super-typhoon Ruping (internationally known as Typhoon Mike) devastated Cebu that for months on end the drinking water supply simply collapsed, and there was no electricity. Packaged water, too, started to disappear from the supermarket shelves; the bottlers’ warehouses were empty. Back then Mr Lua was a building contractor, and had previously visited the USA several times, noticing the remarkable rise in demand for packaged water.

Expansion begins

One year later, Mr Lua imported a reverse-osmosis system from the United States and designed his own small filling line for PVC containers, and for five-gallon polycarbonate water dispensers (approximately 19 liters). In 1994, he installed the firm’s first extrusion blow-moulder for PVC containers, and one year later he started to ship his purified drinking water called “Nature’s Spring” to Luzon. This marked the beginning of the firm’s expansion to its present-day status as market leader in the Philippines’ entire water market.

“Back then, PET containers were really out of the question for us because of the high price for the raw material,” Mr Lua says. “But then the price for PET resin tumbled from about $3,000 a ton to approximately $500 a ton, and that meant the material had become an attractive option for us as well.” In 1996, PSWRI was for the first time producing its own PET containers, with a blow-moulder from Japan. In the end, the company had more than 25 of these relatively low-speed blow-moulders in operation. Most of them have meanwhile been decommissioned and sold.

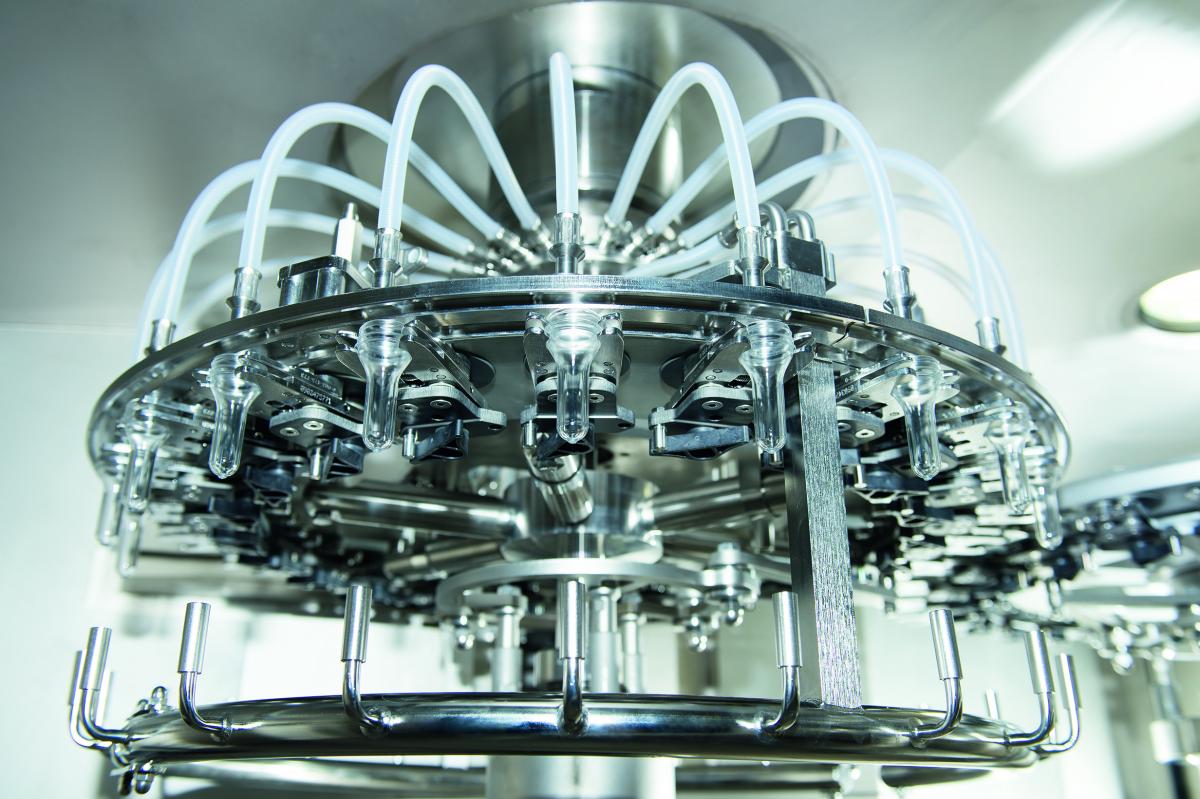

In the Contiform 3, first of all the preforms are decontaminated inside, outside and at the neck finish with gaseous H2O2

Over 30 bottling lines

The expansion thrust took a step forward in 2004, when PSWRI simultaneously inaugurated two new plants in Bulacan and in Cagayan de Oro, Mindanao. This meant that for the first time PSWRI had its own bottling plants in all three major islands, Luzon, Visayas and Mindanao. Today, the family firm operates four large-size facilities, each with five bottling lines, plus two smaller plants. These are complemented by five mini-plants, running one line each. Altogether, PSWRI is thus operating more than 30 lines.

ErgoBloc L – the start of a new era

The new Krones ErgoBloc L line that PSWRI commissioned at its facility in Bulacan in 2014 was the firm’s first bottling line with a high rating of 31,500 containers per hour – the start of a new era for PSWRI: “When Krones unveiled the ErgoBloc L, we were immediately enamored of the idea that we could now blow-mould, label and fill our bottles with just one machine instead of three,” Mr Lua says. What fascinated his son, the Chief Operating Officer (COO) Daniel Ryan L. Lua, most of all is “that with the ErgoBloc L we’re getting a significantly higher efficiency than with our other lines. The higher output enabled us to meet the demand for our products that rose so steeply in 2012 and 2013.”

A wide choice of waters

Competition among the water bottlers is fierce. For the five-gallon containers, in particular, there are thousands of small refill stations. Per-capita water consumption of the 104 million Filipinos is about 50 liters – still leaving up a plenty of potential for the future. PSWRI is offering a wide range of different still waters. Nature’s Spring Purified Water in the five-gallon containers is treated and quality-assured using activated-carbon filtration, softening, reverse osmosis, micro-filtration and ozonization, and packaged in seven different non-returnable PET containers, ranging from 350 milliliters to 10 liters in size. It’s the most popular single-serve water. The company also offers an alkaline drinking water with a pH value of 9.0, assured by means of electrolysis. As its premium drinking water brand, the company has launched products under the “Bai” brand in a 500-milliliter PET bottle.

Aseptic filling: the ideal solution

Since 2012, PSWRI has at its facility in Bulacan been bottling its Iced Tea brand. Iced tea is evolving into a competitor for carbonated soft drinks. It’s precisely this market that the family firm is targeting, but it wanted to upgrade the quality quite significantly by eliminating the preservatives. The ideal solution for this was obvious: aseptic filling. Mr Lua and his son saw the Contiform AseptBloc which was premiered by Krones at drinktec in 2013.

The Contiform AseptBloc offers full-coverage sterility of the production and filling processes for the PET containers. One of the paramount reasons for the savings in time, energy and sterilizing media is the fact that it is not the finished containers that are decontaminated, but the preforms earlier on. Thanks to the significantly smaller surface area involved, and the more even shape of the preforms, media consumption remains substantially lower than with other systems. The Contiform AseptBloc also uses only gaseous hydrogen peroxide, meaning it sterilises the preforms in dry mode, without using any water. This not only reduces water consumption, but also enhances microbiological safety. And the additional kit customarily used in wet-aseptic operations, like a hygiene center or a sterile-water UHT system, is not required here either. The Contiform AseptBloc is also economical in regard to preforms and closures. It uses the process control system (PCS) to continually compute the precise amounts required, thus avoiding sterilization of packaging material no longer needed.

Sterile production and filling

PSWR has installed the Contiform AseptBloc in a cleanroom with a footprint of 35 times 18 meters in a newly built hall. HEPA filters clean the incoming air and with a top-to-bottom laminar flow ensure a sterile environment. Handling in the Contiform AseptBloc begins with a Kosme preform feeder. The PreformCheck inspector uses a camera to monitor the neck finish, while a Prejet blows dust and dirt particles from the preforms; defective preforms are immediately rejected. The preforms then are passed to the blow-moulder by the Contifeed. In the Contiform 3, first of all the preforms are decontaminated inside, outside and at the neck finish with gaseous H2O2. Only then will they be passed to the oven and into the 14 sterile moulds of the Contiform 3.

The replacement moulds are housed in a small sterile room at the back

A small sterile room attached at the rear accommodates the replaceable moulds. From here, the preform moulds can be quickly and hygienically replaced when changing over to a different bottle format. The blow-moulded containers are passed via starwheels into a sterile transfer channel directly to the aseptic Modulfill Asept VFJ filler, whose 66 valves assure microbiological safety through non-contact filling. The fill quantity is determined using a flow meter. Automatic CIP cups support the establishment of perfect hygiene conditions.

From this sterile room the moulds can be quickly replaced when changing over to a different bottle, without compromising hygienic safety

Electronic inspection of fill level and label placement

Simultaneously, on the filler’s roof, the closures are swiftly decontaminated using gaseous H2O2 at high temperatures. Here, too, an inspector ensures that defective closures are automatically rejected. The bottles are capped directly after the filling process. Outside the Contiform AseptBloc, a downstream Checkmat FM-X then inspects the fill level by means of X-rays, and the closure position. The cleanroom also houses a VarioStore sterile tank, in which the product concerned is buffered in a sterile state. The product itself is created by a Contiflow mixer outside the cleanroom, then thermally UHT-treated and sterilised in a VarioAsept J. The VarioClean CIP system is installed here as well. On the opposite side of the cleanroom is the Contiroll HS labeller, in which, after having been dried in a Linadry, the filled bottles are dressed in wrap-around labels. Following another inspection routine featuring a Checkmat E for verifying the label placement, the finished bottles are passed to a discharge conveyor, from where they are (for the time being) manually packed and loaded. The company buys the requisite adhesives and lubricants from KIC Krones, thus ensuring that its machines function to optimum effect.

Ideally suited for lightweighting

Another important goal for PSWRI was to reduce the weight of its containers. The technology of the Contiform AseptBloc is ideally suited for lightweighting, because in contrast to sterilizing finished PET containers, decontamination of the preforms does not cause any PET bottle shrinkage. So the preforms can be designed for a lighter weight right from the start.

PSWRI modified the bottle’s shape and reduced its weight. The previous 220-ml iced tea bottle was a bit lower, but had a larger diameter, and tipped the scales at 9.5 grams. PSWRI has now matched the shape of the iced-tea bottle to the dimensions of the slimmer water bottle, and reduced the preform’s weight to an initial 8.5 grams. “Our target, which we aim to achieve with the Contiform AseptBloc, is a 220ml bottle weighing just seven grams,” explains Danilo Lua. That would be one of the world’s lightest PET containers. PSWRI favors the size, primarily due to the relatively low purchasing power of the local consumers. “People here don’t stock up with water; they buy it from day to day, or even several times a day, as they need it,” explains Daniel Ryan Lua. With the 500ml bottle, PSWRI has already achieved lightweighting down to 11.5 grams with the Contiform AseptBloc. The target is 10.5 grams. So far, the world’s lightest aseptically filled 500-ml PET bottle has a preform weight of 12.0 grams.

Aspiration to market leadership extended to the iced-tea segment

In 2015, the Contiform AseptBloc began bottling iced tea at up to 32,000 containers per hour, in two flavors initially, the first aseptically filled iced tea in the Philippines. The operators have been skilled and trained on-site in control and quality assurance for the Contiform AseptBloc by the Krones Academy, followed up by practical training.

สินค้าออกกำลังกายผู้หญิง คุณภาพ ราคาพิเศษ

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login