EREMA celebrated the global launch of its new innovation, the Intarema (R) RegrindPro (R) during the successful EREMA Discovery Day series, which was held last March 20 in Ansfelden, Austria. The event was attended by more than 200 existing and potential customers and other guests, who maximized the event to gather information about trends, challenges, opportunities, and efficient solutions in the area of post-consumer recycling.

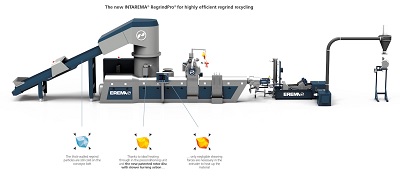

Designed for recycling of regrind materials, the Intarema RegrindPro features extremely gentle processing and highly efficient filtration. It yields maximum pellet quality for a maximum amount of recyclate in the new end product.

The product features a preconditioning unit that allows a slower turning of the patented rotor disc and a longer dwell time to warm thick-walled regrind particles through perfectly. This enables the material to melt in the extruder with minimum shearing forces while keeping the impurities in the melt large enough for filtering out. The Intarema also comes with a gentle universal screw for regrinding materials with varying viscosity such as HDPE and PP.

According to EREMA business development manager for Post Consumer Recycling Clemens Kitzberger, "The EREMA high-performance filter systems additionally ensure continuously high throughput with outstanding melt quality at the same time. With the recently enhanced EREMA Laserfilter, contaminants are removed even more quickly through the redesign of the scraper geometry and discharge system, resulting in even better filtration performance."

The trend for post-consumer recycling is fueling demand for the processing of regrind materials to produce high-quality recycled pellets, particularly in the thick-walled packaging, electronics (WEEE), and automotive sectors. One challenge in this is that thick-walled input materials such as HDPE, PP, ABS, and PS require a specific treatment process for handling mixed fractions with different compositions, high bulk density and moisture, and extremely varying contaminants comprising different impurities such as rubber, silicone, and soft contaminants such as wood and paper, plus foreign polymers like PET and PA.

Further, even as quality of the input material decreases, the requirements for existing applications and demand for exactly specified raw materials from recyclate are rising. The increase in the volume of heavily contaminated post-consumer materials requires new markets and innovative end products with a high percentage of recyclates. These present challenges in recycling solutions.

Kitzberger noted the need for highly efficient recycling technologies as packaging materials become thinner and the relative portion of impurities continues to increase, plus the high residual moisture and degrees of contamination of the input material.

"EREMA has been adapting its technologies continuously to the requirements of the wide variety of recycling applications for more than 30 years. And, as we have also noted a rapidly growing demand for efficient solutions for the processing of thick-walled plastic materials at the current time, we have designed our latest product, the RegrindPro system, to meet the exact requirements in this field of application. Moreover, the product Corema (R) enables the production of exactly specified and application-oriented raw materials based on recyclate. Corema brings together the benefits of recycling and compounding and interest in this technology is growing all the time. This is also the reason why we will be offering our customers access to a workbench for the production of larger test quantities as of autumn 2015."

Expert talks and demonstrations during the Discovery Day 2015 highlighted the Intarema and Corema systems.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login