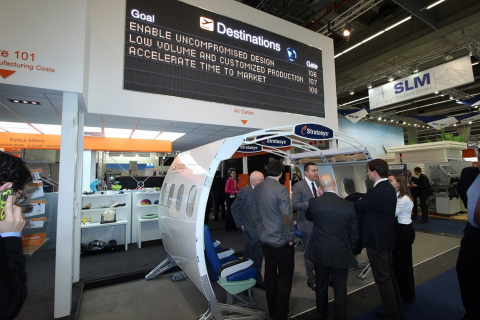

STRATASYS Ltd (Nasdaq:SSYS) demonstrates its additive manufacturing ecosystem at the EuroMold 2014, held November 25 to 28 in Frankfurt, Germany.

The company’s 11 new high-performance 3D printers and materials are designed to provide designers, engineers, and manufacturers with greater flexibility to 3D print prototypes, parts, and final products.

The firm launched its unique triple-jetting technology, which marks a new era in color multimaterial 3D printing, with the debut of the popular Objet500 Connex3 earlier this year. Based on the triple-jetting technology cross-platform, six new PolyJet-based 3D printers enable designers and workgroups to produce prototypes, tools, injection molds, and end-use parts with vivid color and outstanding product realism cost-effectively. The Objet260 Connex1, 2 and 3 series boasts a compact and office-friendly platform. The Objet350 Connex1, 2 and 3 series packs the same features but with bigger build sizes.

The new Objet30 Prime from the PolyJet desktop range provides new levels of material versatility and product realism, quiet operation, and an office-friendly footprint. It offers 12 material options, including rubber-like, rigid, high-temperature, and biocompatible materials.

The new Objet Eden260VS combines ultrafine 16-micron resolution and soluble support technology, ideal for creating delicately detailed models with complex geometries and very thin walls. It promises a lower cost per part for rigid material 3D printing.

Adopting the company’s popular FDM-based technology, the new Fortus 3D Production Systems delivers up to 20 percent quicker build times for complex geometries. It includes the Fortus 380mc and Fortus 450mc. The first is suitable for high-performance prototyping and production tooling in a variety of thermoplastics. The Fortus 450mc features a larger build envelope and the most advanced FDM thermoplastics for midsized functional prototypes, production aids, and end-use parts.

Stratasys has also announced the ULTEM 1010 resin. It features superior heat, chemical resistance, and tensile strength, and biocompatibility.

Air Jordan 30.5 Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login