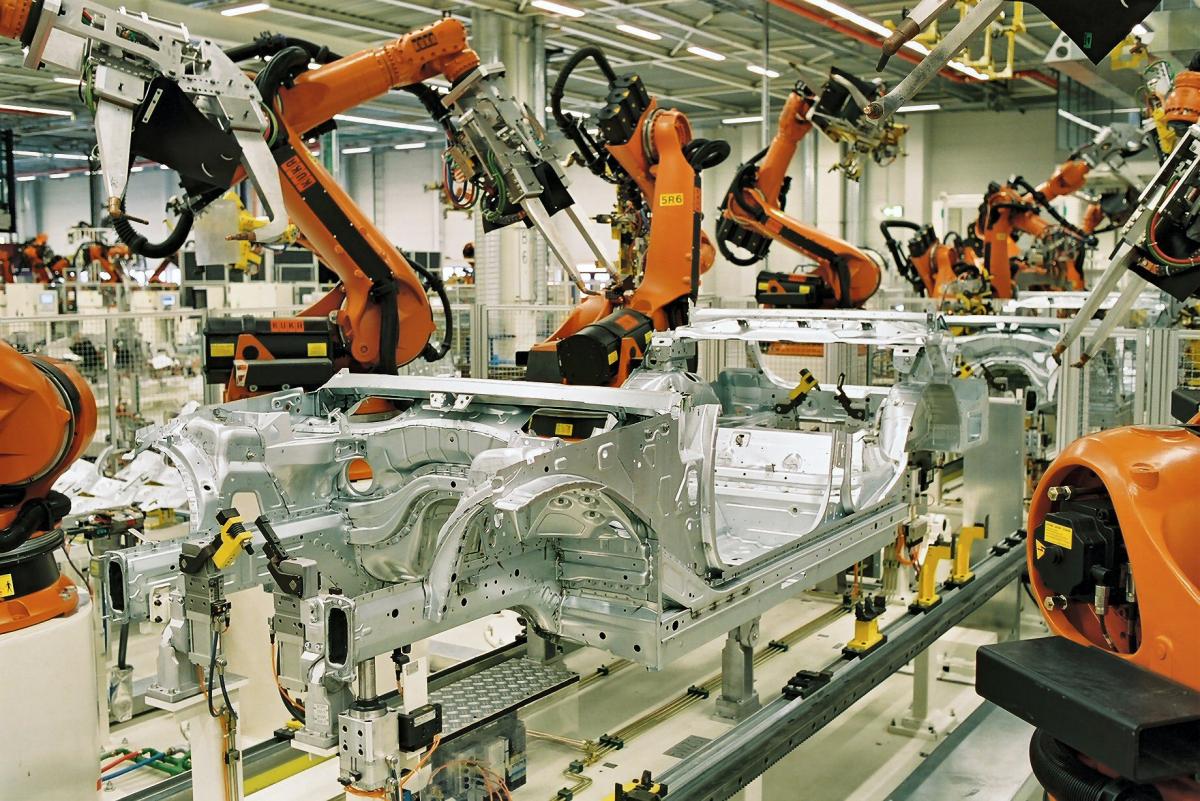

This transformation has been accompanied by mounting challenges in the form of increasing energy demands and the need to constantly reduce the total cost of ownership. End users are constantly looking to adopt solutions that will help them overcome these challenges and have zeroed in on robotics as the logical solution. Amongst all the emerging applications for robotics, welding is a rapidly developing process that is increasingly leveraging the potential that robotics can offer. In the welding sector, robots are likely to improve the quality of work by taking over dangerous or tedious jobs in harsh environments that are not possible or safe for humans to perform.

This trend has started to change with end users understanding the benefits of using advanced solutions in their process. Robotic welding has shown to yield better quality welds with high precision and consistency. Weld penetration has also become stronger, making the joint robust and long lasting. An advantage of robotics over manual is that robotic welding leverages the closed loop feedback system to identify and analyse the parameters involved in the process, thereby ensuring reduced error and prevention of failure. From the welding robotics manufacturer's perspective too there is a push, with vendors trying to increase awareness levels among end users on the benefits of implementing robotics by investing in automation fairs, tradeshows, and workshops.

From an end-user perspective, participants in the heavy machinery and construction market are plagued by the aging workforce and/or limited skilled resources and have started to invest in welding robotics as a means to remain competitive in the market. Moreover, the advent of new materials such as polymers, composites, and carbon fibres, which are increasingly used today to manufacturer components in heavy machinery, automotive, and aerospace industries, presents an opportunity for robots in handling, cutting, or welding of these materials. Robots that can sense changes in material and thickness as well as synchronise welding current with motion control are being developed to enable end users to effortlessly weld these new materials used in production.

Emerging trends such as smart manufacturing and Industrial Internet of Things (IIoT) are also driving the growth of the robotics market. IIoT envisages a future for the manufacturing sector, where information technology (IT) and operational technology (OT) are expected to integrate to form an enterprise ecosystem with product innovation and industry convergence at its core. With this convergence, IT is expected to take on a more central role in the manufacturing sector besides the traditional operational technology and also digitise everything on its part. Eventually, more advanced and complex communication technologies will be incorporated into the industrial sector that will process information at super speed that is beyond human comprehension. Robotics and automated solutions have been designed for the purpose of analysing and comprehending the data and transforming them into actionable outputs such as high precision welding, spray painting, and other similar processes.

While the implementation of robotics in the industrial sector has its pros and cons, it remains to be seen if these advanced solutions will break the traditional mind set and transform the industrial sector of tomorrow.

Source: Frost & Sullivan

Air Jordan XXX 30 Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login