While every attempt is made to focus on Testing Control and Management, we know that testing does not stand alone. It is intimately dependent on the development activity and therefore draws heavily on common sorts of review practices found in software tools. Inspection is one of the most efficient software tools to improve quality and productivity. It is argued that software inspection can easily provide ten times gain in the process of integrated manufacturing, plus reducing verification task from a five-person job to a one-person job. Jeff Cope, owner of Extensible CAD Technologies LLC, works to solve the needs of small- and medium-sized manufacturers that work in industries where product quality is paramount. His products particularly, InspectionXpert, is well represented in the oil and gas industry. " Software inspection can easily provide ten times gain in the process of integrated manufacturing, plus reducing verification task from a five-person job to a one-person job." Producers of oil and gas in the Middle East are currently investing heavily to increase production rates and greater operational efficiency. Jeff explains to International Metalworking News- Middle East how the advancement of InspectionXpert deliver value for any given set of circumstances in the oil and gas industry. "Oil and gas companies face different challenges than companies in other industries," Cope says. "In automotive for instance, parts are being mass produced and after the initial first-article inspection, hundreds or thousands of parts may be manufactured before another First-Article Inspection is required. Other types of inspection, such as in-process inspection are done during this time but those inspections aren't nearly as comprehensive and therefore labour-intensive, as first-article inspection. With oil and gas, it is different," he describes. "We usually see our oil and gas customers creating small quantities or 'short runs' of each part but those parts tend to be very complex with hundreds of dimensions each. It is very important that the parts are made to specification too because human life and huge sums of money are at risk if the parts fail in the field. InspectionXpert has been very well received in the oil and gas industry thus far because it dramatically reduces the pain associated with these frequent inspections," he adds. When asked what ordeals the oil and gas market is throwing up at software solution providers, such Extensible CAD Technologies, Jeff says that the biggest trial is getting people to sit still for long enough to see InspectionXpert in action. "The oil and gas companies we speak to are usually so overwhelmed with these inspections that it is hard to get them to set aside time to see how to speed up and error-proof the process. I guess it is the old 'too busy chopping wood to sharpen the axe' conundrum."

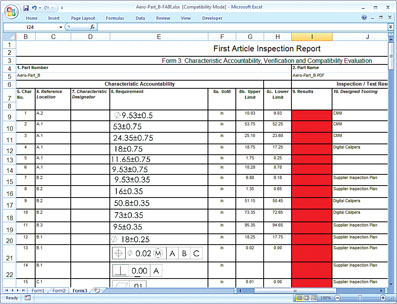

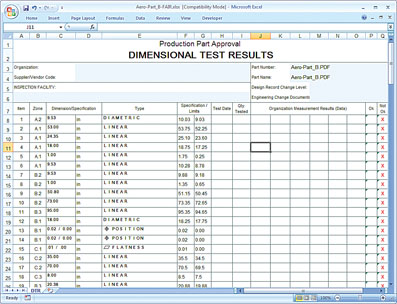

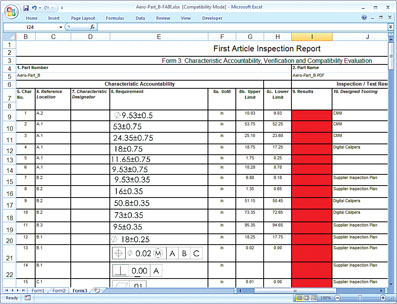

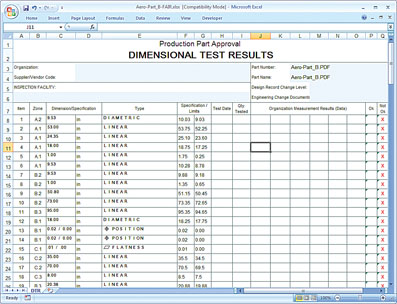

Ten times gain "To understand how a software inspection program can help companies achieve up to 90% time savings, I have to tell you a little bit about the process that InspectionXpert replaces. Most companies perform their inspections from a 2D drawing and type the inspection results into an Excel file. The drawing is typically printed up and then "ballooned" by taking a red pen and drawing little circles next to each dimension. Numbers are written into each balloon to uniquely identify each dimension and note to be inspected. These items to be inspected are called "inspection characteristics." After ballooning the drawing by hand, the inspector then types the identifiers, values, units and tolerances for each inspection characteristic into a spreadsheet or table of some sort. As the number of dimensions in drawing increases, so does the possibility of human error in transcribing these inspection characteristics. The sad thing is that all of the information that they

Nike Free Rn Flyknit

Ten times gain "To understand how a software inspection program can help companies achieve up to 90% time savings, I have to tell you a little bit about the process that InspectionXpert replaces. Most companies perform their inspections from a 2D drawing and type the inspection results into an Excel file. The drawing is typically printed up and then "ballooned" by taking a red pen and drawing little circles next to each dimension. Numbers are written into each balloon to uniquely identify each dimension and note to be inspected. These items to be inspected are called "inspection characteristics." After ballooning the drawing by hand, the inspector then types the identifiers, values, units and tolerances for each inspection characteristic into a spreadsheet or table of some sort. As the number of dimensions in drawing increases, so does the possibility of human error in transcribing these inspection characteristics. The sad thing is that all of the information that theyNike Free Rn Flyknit

Ten times gain "To understand how a software inspection program can help companies achieve up to 90% time savings, I have to tell you a little bit about the process that InspectionXpert replaces. Most companies perform their inspections from a 2D drawing and type the inspection results into an Excel file. The drawing is typically printed up and then "ballooned" by taking a red pen and drawing little circles next to each dimension. Numbers are written into each balloon to uniquely identify each dimension and note to be inspected. These items to be inspected are called "inspection characteristics." After ballooning the drawing by hand, the inspector then types the identifiers, values, units and tolerances for each inspection characteristic into a spreadsheet or table of some sort. As the number of dimensions in drawing increases, so does the possibility of human error in transcribing these inspection characteristics. The sad thing is that all of the information that theyNike Free Rn Flyknit

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login