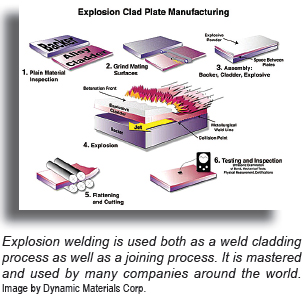

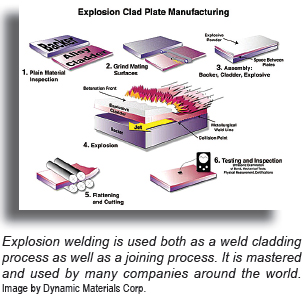

Explosion welding or bonding is a solid state welding process that is used for the metallurgical joining of dissimilar metals. The process uses the forces of controlled detonations to accelerate one metal plate into another creating an atomic bond. Explosion bonding can introduce thin, diffusion inhibiting interlayer, such as tantalum and titanium, which allow conventional weld-up installation. Also explosive welding is considered a cold-welding process which allows metals to be joined without losing their pre-bonded properties. One of the most common uses of explosion welding is for applying a relatively thin cladding or covering of some material providing special characteristics (like outstanding resistance to corrosion, or wear, or heat) onto a base metal, generally thicker, designed to provide a suitable support for engineering applications. The combination of an inexpensive support and an expensive, specialised cladding provides a cost effective solution for those cases where making the parts with monolithic (one piece) material would result in a prohibitively costly solution. Another use is for manufacturing of transition pieces of dissimilar materials, to permit the subsequent welding of additional components of those materials by common welding processes. Two surfaces to be joined by explosion welding are initially spaced at a small stand-off distance that typically varies from 0.5 to 4 times the thickness of the cladder sheet. The material to be clad must exhibit sufficient ductility and fracture toughness to stand the mechanical deformation needed to perform explosion welding without being shattered. Usual limits are minimum elongation of 15 % and notch toughness value of 30 J at process temperature. Explosion welding deforms the metals at very high rates (104 up to 105 per sec). The usual setup includes a massive plate or anvil supporting the base plate. The cladding material, called clad or flyer plate, covered with the chemical explosive, in uniformly distributed granular form or as a plastic sheet, is held parallel or at an angle to the base metal at the correct standoff distance, that is necessary to develop the speed needed at the impact.

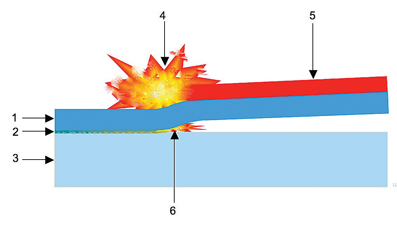

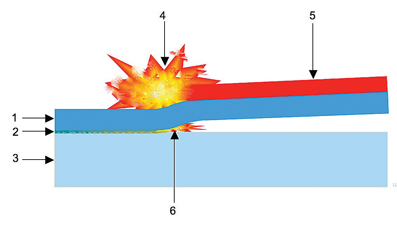

Explosion welding is produced as the cladding material is accelerated at high speed against the static base metal. The explosive material is ignited at a predetermined point on the plate surface using a high velocity explosive booster. The explosive force brings the two surfaces together progressively at the collision front. The detonation travels away from the initiation point and across the plate surface at the specified detonation speed. The gas expansion of the explosive detonation accelerates the cladding plate across the standoff gap, resulting in an angular collision at the specified collision velocity. Upon progressive detonation of the explosive, from the starting edge to the opposite one, the deformation force runs at high speed across the whole surface of the cladding material. This force causes the clad metal to form a moving bend that collides with the base metal at a rapidly sweeping line, made of all the collision points in every section of the plates. The resultant impact creates very high localised pressures at the collision points. The interfacial pressure at the collision front must exceed the yield strength of the materials, so that plastic deformation will occur. These pressure waves travel away from the collision point at the acoustic velocity of the metals. Since the collision line is moving forward at a lower, subsonic rate, pressures are created at the immediately approaching adjacent surfaces, forming a jet of metal just ahead of the collision front. The jet, included within the two component surfaces, is sufficient to spall a thin layer of metal from each surface and eject it away

Adidas Explosion welding or bonding is a solid state welding process that is used for the metallurgical joining of dissimilar metals. The process uses the forces of controlled detonations to accelerate one metal plate into another creating an atomic bond. Explosion bonding can introduce thin, diffusion inhibiting interlayer, such as tantalum and titanium, which allow conventional weld-up installation. Also explosive welding is considered a cold-welding process which allows metals to be joined without losing their pre-bonded properties. One of the most common uses of explosion welding is for applying a relatively thin cladding or covering of some material providing special characteristics (like outstanding resistance to corrosion, or wear, or heat) onto a base metal, generally thicker, designed to provide a suitable support for engineering applications. The combination of an inexpensive support and an expensive, specialised cladding provides a cost effective solution for those cases where making the parts with monolithic (one piece) material would result in a prohibitively costly solution. Another use is for manufacturing of transition pieces of dissimilar materials, to permit the subsequent welding of additional components of those materials by common welding processes. Two surfaces to be joined by explosion welding are initially spaced at a small stand-off distance that typically varies from 0.5 to 4 times the thickness of the cladder sheet. The material to be clad must exhibit sufficient ductility and fracture toughness to stand the mechanical deformation needed to perform explosion welding without being shattered. Usual limits are minimum elongation of 15 % and notch toughness value of 30 J at process temperature. Explosion welding deforms the metals at very high rates (104 up to 105 per sec). The usual setup includes a massive plate or anvil supporting the base plate. The cladding material, called clad or flyer plate, covered with the chemical explosive, in uniformly distributed granular form or as a plastic sheet, is held parallel or at an angle to the base metal at the correct standoff distance, that is necessary to develop the speed needed at the impact.

Explosion welding or bonding is a solid state welding process that is used for the metallurgical joining of dissimilar metals. The process uses the forces of controlled detonations to accelerate one metal plate into another creating an atomic bond. Explosion bonding can introduce thin, diffusion inhibiting interlayer, such as tantalum and titanium, which allow conventional weld-up installation. Also explosive welding is considered a cold-welding process which allows metals to be joined without losing their pre-bonded properties. One of the most common uses of explosion welding is for applying a relatively thin cladding or covering of some material providing special characteristics (like outstanding resistance to corrosion, or wear, or heat) onto a base metal, generally thicker, designed to provide a suitable support for engineering applications. The combination of an inexpensive support and an expensive, specialised cladding provides a cost effective solution for those cases where making the parts with monolithic (one piece) material would result in a prohibitively costly solution. Another use is for manufacturing of transition pieces of dissimilar materials, to permit the subsequent welding of additional components of those materials by common welding processes. Two surfaces to be joined by explosion welding are initially spaced at a small stand-off distance that typically varies from 0.5 to 4 times the thickness of the cladder sheet. The material to be clad must exhibit sufficient ductility and fracture toughness to stand the mechanical deformation needed to perform explosion welding without being shattered. Usual limits are minimum elongation of 15 % and notch toughness value of 30 J at process temperature. Explosion welding deforms the metals at very high rates (104 up to 105 per sec). The usual setup includes a massive plate or anvil supporting the base plate. The cladding material, called clad or flyer plate, covered with the chemical explosive, in uniformly distributed granular form or as a plastic sheet, is held parallel or at an angle to the base metal at the correct standoff distance, that is necessary to develop the speed needed at the impact.  Explosion welding is produced as the cladding material is accelerated at high speed against the static base metal. The explosive material is ignited at a predetermined point on the plate surface using a high velocity explosive booster. The explosive force brings the two surfaces together progressively at the collision front. The detonation travels away from the initiation point and across the plate surface at the specified detonation speed. The gas expansion of the explosive detonation accelerates the cladding plate across the standoff gap, resulting in an angular collision at the specified collision velocity. Upon progressive detonation of the explosive, from the starting edge to the opposite one, the deformation force runs at high speed across the whole surface of the cladding material. This force causes the clad metal to form a moving bend that collides with the base metal at a rapidly sweeping line, made of all the collision points in every section of the plates. The resultant impact creates very high localised pressures at the collision points. The interfacial pressure at the collision front must exceed the yield strength of the materials, so that plastic deformation will occur. These pressure waves travel away from the collision point at the acoustic velocity of the metals. Since the collision line is moving forward at a lower, subsonic rate, pressures are created at the immediately approaching adjacent surfaces, forming a jet of metal just ahead of the collision front. The jet, included within the two component surfaces, is sufficient to spall a thin layer of metal from each surface and eject it awayAdidas

Explosion welding is produced as the cladding material is accelerated at high speed against the static base metal. The explosive material is ignited at a predetermined point on the plate surface using a high velocity explosive booster. The explosive force brings the two surfaces together progressively at the collision front. The detonation travels away from the initiation point and across the plate surface at the specified detonation speed. The gas expansion of the explosive detonation accelerates the cladding plate across the standoff gap, resulting in an angular collision at the specified collision velocity. Upon progressive detonation of the explosive, from the starting edge to the opposite one, the deformation force runs at high speed across the whole surface of the cladding material. This force causes the clad metal to form a moving bend that collides with the base metal at a rapidly sweeping line, made of all the collision points in every section of the plates. The resultant impact creates very high localised pressures at the collision points. The interfacial pressure at the collision front must exceed the yield strength of the materials, so that plastic deformation will occur. These pressure waves travel away from the collision point at the acoustic velocity of the metals. Since the collision line is moving forward at a lower, subsonic rate, pressures are created at the immediately approaching adjacent surfaces, forming a jet of metal just ahead of the collision front. The jet, included within the two component surfaces, is sufficient to spall a thin layer of metal from each surface and eject it awayAdidas

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login