Inspirtations through art

Philip Norman isn’t really an Engineer by profession. He is a Literary Enthusiast, Published Author, an artist and an inventor. But he has traversed a new terrain, extending the boundaries of advanced robotics.

Since the interactions between engineering and art have not always been naturally easy, the insertion of a third party into the design and production of modules that fit together and can be configured in a variety of ways. When looked at from an outsider’s point of view, the two teams may have more in common than they realise.

Philip shared colorful stories of his past and how he turned a design concept into a tangible, functioning product.

IMNA: Please describe Ross Robotics and what it does.

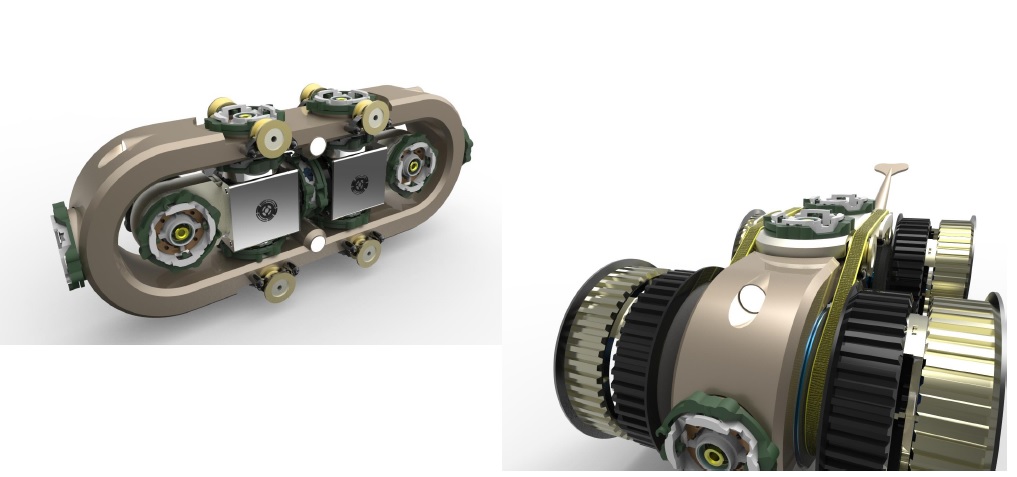

Philip Norman: Ross Robotics produces rugged, high-performance robots that are adapted to the task and to the operating conditions. Using an open architecture, the company standardises robot technology and the Robosynthesis Modular Platform creates a wide range of special-capability robots from a set of generic parts. The company harnesses manufacturing economies of scale to reduce cost without sacrificing engineering excellence.

IMNA: What inspired you to assemble reconfigurable robots, can you tell us about your journey- from art to advanced technology?

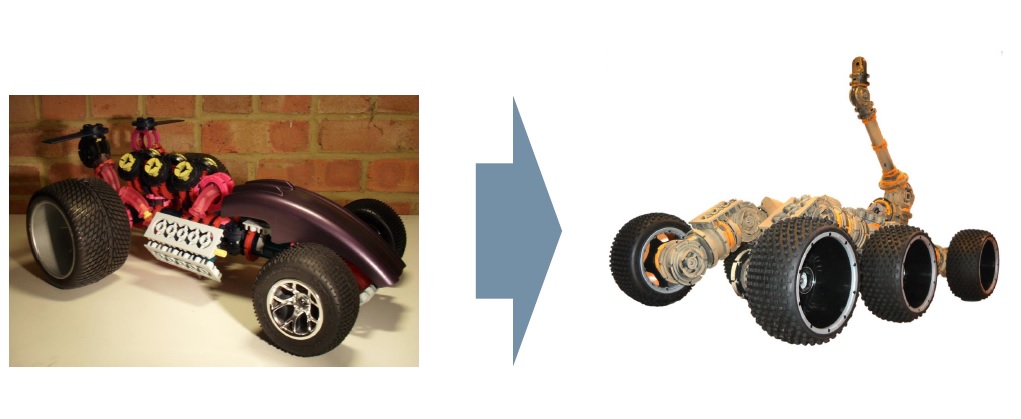

Philip Norman: I was inspired by art and nature. For instance a salmon swimming upstream, as robust as an armadillo. It can climb and creep like a gecko. It has the aptitude of a chimpanzee to utilise tools and the capacity of a cockroach to withstand extreme and hazardous environments. Solving puzzles was the first step. Then came an epiphany from a child’s toy robot. I was living in France and exploring the concept of a new construction toy. This is when the Robosynthesis Modular Platform was conceived. I mentioned this to an engineer friend who introduced me to Solid Edge® software.

IMNA: What has been the experience like when you first started using Solid Edge?

Philip Norman: What had begun as a rather dreamy intellectual idea became sharp and clear. It was a watershed moment when I realised I could simply sketch, then extrude to create a 3D shape. I went on to discover that I could put bits together and create an assembly or place parts in a library and take them out later. There was a sense of pure delight when I updated a part I’d built and it updated in the assembly as well. To top all of this, I could break up an assembly and go back to where I was. There are clearly lots of little ‘Eureka!’ moments as a user becomes quicker and more confident.”

IMNA: So what led you to modular robotics?

Philip Norman: Education was the main theme for me for several years, providing school and technical college students with an opportunity to study mechatronics and prototyping through programs at IFMA, the advanced mechanical engineering institute in Clermont-Ferrand. A suggestion from a family member then led me to modular robotics. I realised that I needed to drive this to a tangible outcome, and I became really focused. However the main challenge was to create and build one part that could join components together and rotate.

IMNA: Tell us more about these reconfigurable robots.

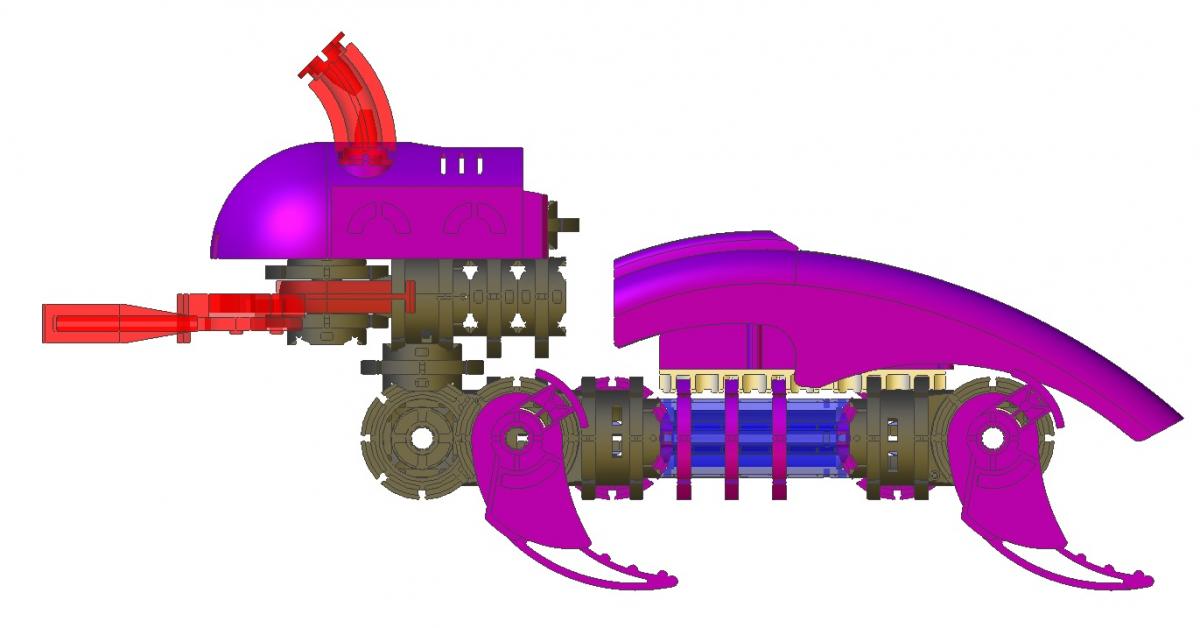

Philip Norman: I solved the answer of joining components together and rotate through the form of a universal connector that fixes in any direction. Having solved the problem of physical connectivity, I set out to create a means of data connectivity. A special jack plug designed to absorb vibration and withstand force carries electrical channels through its core and provides communication, data transfer and power charging capabilities. I was inspired by the webbed feet of ducks when I created the wheel system. This system enables a robot to manoeuvre up steps and over unstructured surfaces such as bramble bushes. Decision-making can sometimes bring creativity to a close and I wanted to continue in a state of uncertainty until I was absolutely sure. I found that I could chop and change very quickly before I actually decided.

Pursuing the animal theme, I designed the robots to have a low centre of gravity for stability and a tail that acts as a damper and prevents flipping. Parts are deliberately springy and flexible so that the robots are both agile and resilient. Components are manufactured by tooling a computer numerical control (CNC) machined master, then vacuum casting in a variety of plastics. We use plastics because rigid things break easily and production costs are lower. However, we coat these plastics in a fine layer of metal instead of using separate metal components. This metallization process, which we applied to the universal connector, enables us to make parts that are strong, cheap and light. Material science has been a whole new learning curve for me. I’ve picked up a lot of knowledge about different aspects such as how to design parts for strength and flexibility.

IMNA: Any words you can share to our readers? Your story is truly very inspiring.

Philip Norman: Be flexible and open in your journey. Be Confident that you can get the answer. Design Inspiration is all around you - in nature, art and life.

From a child's toy to a robot

Building the brand through visualisation

Introducing Robosynthesis

Click to view E-zine: International Metalworking News for Asia – Dec issue

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login