The 28th Fakuma international trade fair for plastics processing is eagerly awaited by all industry players, because this world’s leading trade fair for the injection moulding sector promises new impetus in numerous areas. The trade fair highlight is regarded as a technology barometer for the fields of extrusion technology, thermoforming and 3D printing. Once again this year, the exhibition focuses on the challenges of digitalisation, process automation, energy efficiency and circular economy. Another important objective of Fakuma involves the presentation of plastics processing in the intelligently networked factory of tomorrow.

An important focus of Fakuma 2023 is on how the highly complex subject of plastics can be incorporated into climate protection and circular economy. As the future of the industry lies on how it can move towards this model, the exhibitors are keen on showing how they respond to the challenges of circular economy and sustainability with tremendous innovative drive and dynamics.

Fakuma takes place on October 17-21, 2023 at Messe Friedrichshafen with around 1,500 exhibitors showcasing their range of products and services. Despite its European setting, roughly 40% of the exhibitors come from outside Germany.

Here's an overview of the innovations at this year’s Fakuma.

ARBURG: Efficient injection compression moulding

Arburg presents an electric Allrounder 720 A "Ultimate" as a highlight to demonstrate how high-quality injection moulding technology can be an alternative to thermoforming. The exhibit uses injection compression moulding to produce thin-walled IML cups that can be easily recycled after use. The directly driven high-performance machine with a clamping force of 2,900 kN is equipped with a size 1300 injection unit that is specifically optimised for high performance. Thanks to high-precision servo motors from Arburg's sister company AMKmotion, very high injection volume flows and injection speeds of up to 400 millimetres per second can be achieved.

The exhibit uses a 4-cavity mould from Brink to produce thin-walled IML round cups from polypropylene (PP) using the injection compression moulding process. The flowpath/wall thickness ratio is 380:1. For process monitoring, the mould is equipped with six high-resolution inductive position measuring and embossing sensors. Four moulded parts, each weighing 10.8 grams and with a wall thickness of only 0.37 millimetres, are produced in a cycle time of 3.95 seconds. The plastic has a biomass footprint and ISCC-certified. Also integrated into the production cell is a side-entry robot from Brink that inserts the labels, removes the finished cups and stacks them on a conveyor belt.

In this particularly resource-saving application for the packaging industry, special emphasis was placed on energy efficiency and on a part design that saves materials. Thanks to the all-electric packaging machine in combination with injection compression moulding, the energy footprint is improved by 20% with a significant reduction in part weight from 13 to 10.8 grams. Meanwhile, the flowpath/wall thickness ratio is 380:1. Normally, this would require a very high level of injection pressure – at the expense of energy requirements and mould wear. This is why injection compression moulding is used for this application. Compared to classic injection moulding, this process requires significantly less injection pressure and it is possible to work with mould temperatures of 20 instead of 12 degrees Celsius. The special "Next Cycle IML" label can be completely separated from the PP of the cup during recycling, so that the product can be recycled by type after use. In contrast to thermoforming, no pre-produced foils are used and no stamping waste is produced.

Asahi Kasei: Diversified material solution for EV batteries

Japanese technology company Asahi Kasei showcases diversified material solutions for safe and compact EV batteries, improved connectivity and lightweighting, as well as circular economy at Fakuma. This year, Asahi Kasei puts a special focus on its broad range of materials for lightweight, compact, and safe electric vehicle battery solutions. The company is currently developing a new continuous glass fibre reinforced thermoplastic, LENCEN™, and presents it for the first time at the exhibition. This composite material is formed by stacking layers of continuous glass fibre textiles with polyamide 66 (PA66) films. Due to its tensile strength, high heat resistance, and impact properties similar to metal, this material improves collision safety and weight reduction of EV batteries.

In addition, the company showcases a carbon fibre reinforced thermoplastic unidirectional tape (CFRTP-UD tape) that utilises both recycled continuous carbon fibre and the company’s LEONA™ polyamide resin. Boasting a higher strength than metal, this CFRTP-UD tape can be applied to automobile frames and bodies, further enabling the recycling of end-of-vehicle-life parts into different, new automobile parts. Asahi Kasei also presents cooling pipes for EV battery packs made of the modified polyphenylene ether (m-PPE) XYRON™, as well as 2170 cell trays based on the m-PPE particle foam SunForce™. One highlight of its exhibit is the bio-based and biodegradable cellulose nano fibre (CNF). This material is made from cotton linter and features a high heat resistance and network-forming ability. CNF-reinforced polyamide shows a thixotropic behaviour, making it highly suitable for 3D printing applications in terms of easy printing, dimensional accuracy, smooth appearance, and mechanical performance. Furthermore, CNF has superior material recyclability compared to glass fibres. In addition, the company present its comprehensive solutions for establishing a sustainable life cycle for PA66 utilising bio-based feedstock and a new technology for chemical recycling. Together with Japanese partner company Microwave Chemical, the company is working on a new technology for chemical recycling of PA66. The process utilises microwaves to depolymerize automotive airbags and other PA66 parts and directly obtain the monomers hexamethylenediamine (HMD) and adipic acid (ADA), which is expected to be accomplished at high yield with low energy consumption. The monomers obtained can then be used to manufacture new PA66.

Frigel: Latest developments in cooling and mould temperature control solutions

Frigel Group joins Fakuma to present its latest process cooling solutions, designed especially for the following plastics fields: automotive, packaging, medical, chemical, pharmaceutical, household, etc. At Fakuma, Frigel officially launches to the market the Microgel SYNCRO, the new machine-side unit that revolutionises the temperature control method for injection moulding. Microgel Syncro technology provides for a drastic reduction in cycle time (up to 40%), while maintaining the surface quality, dimensional characteristics and mechanical performance of the finished product. The reduction of the total cycle time is obtained thanks to the reduction of the cooling time only: this result, achieved through the digital synchronization with the moulding machine, has the great advantage of not requiring modifications of the other moulding parameters, with the unit communicating with the press but remaining completely autonomous and easily implemented by the operators.

The Microgel SYNCRO product line features more than 10 models, with cooling capacities from 16 kW to 56 kW and heating capacities from 12 kW to 24 kW. The big difference compared to the traditional method consists in the fact that the Syncro control unit supplies cold water to the mould only during the cooling phase, drastically reducing its duration. The advantages for the customer are easily understood: increased productivity and profitability of the dedicated production cell, against an investment with an average payback time of less than 6 months.

Frigel has also expanded its Adiabatic product family line, introducing the Ecodry MDK range, designed for flexible configuration of modular adiabatic solutions for small to large plastic factories. MDK takes advantage of some of the technological advances already introduced in the LDK range (new efficient PADs, new generation of EC fans, modular design, wide and deep configuration). MDK is characterised by a high efficiency humidification system (COOLPAD™) and by a new generation of EC fans which, combined with a more effective dry cooler, obtain a new level of compactness in a powerful new adiabatic cooler product line. The new Ecodry MDK is designed to integrate easily into existing Ecodry 3DK systems, of which Frigel has an existing installation base of thousands of units, in addition to responding to the new needs of industries, including energy efficiency, sustainability and saving of raw resources such as water.

The 3PR 4.0 product platform is a dedicated Frigel solution that provides complete control of Frigel central cooling systems. 3PR 4.0 control meets the needs of processors to supervise and manage the whole cooling system from a single control point. All the connected central system components are controlled via a unique control panel that has been designed specifically for Frigel systems. 3PR 4.0 is available in two versions, Lite and Premium, depending on the size of the system and the equipment to control. Full native connectivity to MiND™ and its new HMI (Human Machine Interface) offer a flawless user experience and compatibility with Industry 4.0 architectures, providing easy visualization and process diagrams of the connected equipment, dashboards for main parameters, performance graphs and alarm management and history.

MAAG: Innovative solutions for a circular economy

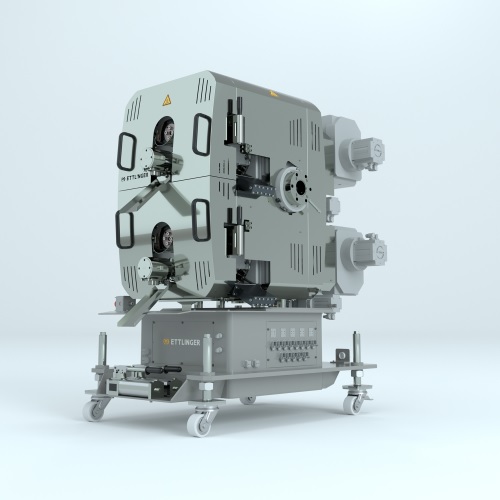

MAAG Group is a broadly diversified global solutions provider of Pump & Filtration Systems, Pelletizing & Pulverizing Systems, Recycling Systems and digital solutions. At Fakuma, MAAG presents its AMN die plates for highest quality requirements for throughputs up to 100 t/h. Specifically designed to produce high MI or complex polymers, the CIS system increases the water flow locally to facilitate cutting, improve pellet quality and reduce cavitation phenomena. Easily plugged on existing installations, the additional water flow is then efficiently distributed thanks to the knife holder equipped with a cone and saber knives, facilitating pellet cooling and ejection. Another product is MAAG ETTLINGERs ECO 500, a high performance melt filter for the filtration of heavily contaminated polymer feedstock. For chemical recycling, this technology is outstanding for filtering low viscosity polymers. The filter is self-cleaning with a rotating, perforated drum, through which there is a continuous flow of melt from the outside to the inside. A scraper removes the contaminants that are held back on the surface and feeds them to the discharge system. This enables the filter to be used fully automatically and without any disruptions over long periods without having to replace the screen. The advantages: Reliable melt filtration, ultra-low melt losses constant pressure curve, fast spreading of the contamination and short residence time of the melt in the filter.

The underwater pelletizing system PEARLO® 350 EAC is shown. The system especially designed for high throughputs of like 18.000 kg/h of Virgin Polymer production. The unique cutting blade design and optimum water and material flow conditions within the cutting chamber provide not only ideal and homogeneous cooling effects but also outstanding pellet quality. Another innovative design feature of the PEARLO is the cutting blade advance system, which permits axial movement of the cutter shaft resulting in a precise blade advance as well as a regrinding of the blades during production. This allows higher equipment availability, elongated production runs and thus saves costs. MAAGs strand pelletizing system EBG is designed for highly filled, hydroscopic and water-sensitive compounds. EBG scores with a high degree of automation, gentle material processing and excellent product quality. From the die head to the granulator, the pelletizing system forms a unit that, despite its compact design, has features of a large compounding system.

MAAG Group extrex® gear pumps offer an optimised interaction of the components. Specially developed gear teeth with low compression allow very high pressures to be achieved with low shear rates. The result is a further increase in achievable product quality, volumetric efficiency, as well as production consistency and safety.

SIKORA: Testing and quality control of hose, tubes and pipes

SIKORA presents trendsetting solutions for quality control in the hose, tube and pipe as well as plastics industry. The trade show appearance is in line with the motto "Ideas, Passion, Future", which SIKORA has developed for its 50th anniversary. How to reliably sort plastic material is demonstrated by the modularly developed PURITY SCANNER ADVANCED. In addition to optical 25 µm high-resolution cameras, which detect black specks and discolourations, an X-ray camera ensures the detection of metallic contamination. By using a third camera in the SIKORA system, a significantly higher detection rate is achieved, so that more contaminations are detected. The interaction of reliable detection and intelligent sorting ensures highest material quality. At the same time, production processes are optimised, which contributes to a cost-efficient and sustainable production. At the SIKORA booth, visitors are able to inspect and analyse small quantities of crystalline and amorphous pellets, flakes or test plates for contamination with the inspection and analysis system PURITY CONCEPT V. The system is suitable for reproducible laboratory applications and detects black and colored contamination from a size of 50 µm as well as discolourations.

In the area of extrusion, SIKORA presents the CENTERWAVE 6000/250 for the measurement of tubes in the diameter range from 32 to 250 mm during production based on millimeter wave technology. All dimensions of the tube, such as the diameter and the wall thickness, are determined and visualised in real time over 360 degrees of the pipe circumference. The measurement data obtained enables automatic control of the minimum wall thickness, taking into account the standard deviation of the extrusion line. This allows potential savings to be exploited to the maximum. In the line, the system enables gapless, reliable quality control as well as automatic control. Another highlight is SIKORA’s X-ray technologies for quality control that enables manufacturers a reliable inline quality control of stranded products. How to reliably measure different layers of tubes and hoses during the extrusion process is demonstrated at the SIKORA booth by the X-ray measuring system X-RAY 6000 PRO in combination with the processor system ECOCONTROL 6000. At the 22" monitor the measuring values are displayed numerically as well as graphically as trend and statistical data. By default, the wall thickness is displayed at eight measuring points. In addition, an intelligent physical evaluation model determines the minimum wall thickness, i.e., the available value, which optimally supports the user in controlling the process. For products where a single layer measurement is required, SIKORA presents the X-RAY 6000 PURE to the Fakuma visitors. Also using X-ray technology, the device measures single-layer products as well as the total wall thickness of multi-layer products and covers with two models product diameters from 6 to 110 mm. The measured values are visualised on a 15" display; if required, automatic control to minimum wall thickness is also possible. Ensuring quality while saving material leads to a significant increase in productivity and also contributes to save CO2 and thus to protect the environment.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login