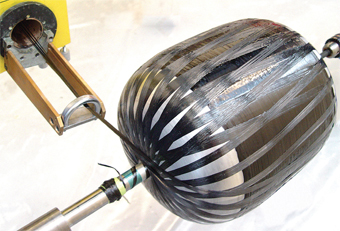

Filament winding is a fabrication technique for creating structures using fibre-reinforced plastics or composite materials. The process involves winding filaments under tension over a male mould or mandrel. In the simplest form of winding, the mandrel rotates on a spindle around a horizontal axis, while a carriage moves backward and forward horizontally, laying down fibres in the desired pattern. The most common filaments are carbon fibre, glass fibre and aramid fibre (eg 'Kevlar'). These fibres are coated or impregnated with a liquid synthetic resin just before they are wound in the process known in the composites industry as 'wet-winding'. However, it is also possible to filament wind fibres which have been 'pre-impregnated' with a solid, but flexible resin that hardens only when exposed to heat. Once the mandrel is completely covered to the desired thickness, the mandrel might be placed in an oven to solidify (cure) the resin. However, with many resin systems it is also possible to conduct room-temperature cures. Once the resin has cured, the mandrel is often removed, leaving a hollow final product. However, some products such as pressure vessels permanently leave the mandrel inside the composite reinforcement, and it becomes an integral part of the final product. In the case of pressure vessels, what was used as a mandrel during the winding process, acts as a 'liner' (to maintain a seal and prevent the leaking of a pressurised gas or liquid inside) during operation. Suited to automated production Filament winding is well suited to automation and is a relatively inexpensive method of automated production and prototyping. Using computer control, the orientation of the filaments can be carefully controlled so that the fibres of one layer are oriented differently from the previous layer. The angle of the fibre orientation determines the structural properties of the final product. A high angle "hoop" or "circumferential" layer will improve crush strength, while a lower angle pattern (known as a closed or helical) will provide greater strength in the longitudinal direction.

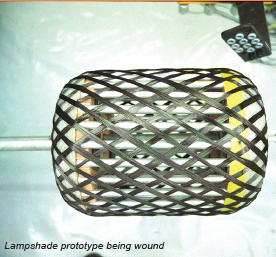

There are a wide range of products currently being produced using this technology, for example: pressure-vessels, pipes, water and other tanks, golf club shafts, oars, bicycle forks and tubes, power and transmission poles, missile casings, aircraft fuselages, lamp posts, yacht masts and booms. A software, known as CADWIND, simulates the movement of the winding machine's movable components. Each movable component is commonly referred to as an 'axis' and a winding machine may have anywhere from 2 (spindle rotation and carriage movement) up to 6 individual axes (typically: spindle, carriage, cross-carriage, pay-out eye rotation, pay-out eye yaw and pay-out eye vertical movement), all of which must be controlled in a coordinated and very precise way to produce the desired result. At the same time as simulating the machine movements, CADWIND also simulates the laying of the fibres onto the mandrel surface. This allows many different analyses to be performed on the build-up of the material thickness, variations in fibre angles, etc. Hence, a wide range of manufacture problems can be avoided without wasting valuable material and time working with the machine. This greatly reduces the time and cost spent developing a new product. Finally, CADWIND uses the results of its simulations to produce a computer file (or files) that can be sent directly to the filament winding machine's computer numerical controller (CNC) software, ready for winding. Process simulation software in filament winding technology Founded in 1990 by former engineers of the Institute for Plastic Processing in Germany, MATERIAL has been providing engineering services and software for the composites industry worldwide. MATERIAL's software system CADWIND hNike Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login