It does not push, drag, or impart force that might bend a part or cause flex that would have a negative impact on process control.

It also offers minimal thermal input, with fine control over how hot the work area gets. This is important since small parts heat up quickly and might otherwise overheat or deform.

Laser cutting is highly focusable to about 25 microns, which is about ¼ of the width of a strand of human hair. This makes it feasible to remove a minimal amount of material when making the cut, resulting in extremely high precision and high accuracy.

The laser cutting technology has extremely fine control of pulse width, power, and focus spot size. Because the laser cutting tool does not rely on touching the part, it can be oriented to make any shape or form. Not limited by physical cutting geometry, laser cutting can be used to make unique shapes.

Laser cutting systems for medical tools

The laser technology most frequently used to make medical tubes and components is fiber laser cutting with gas assist. This means that the laser is “assisted” with a coaxial gas, typically oxygen (O2). While O2 is usually the gas of choice, occasionally an inert gas may also be used according to the material or application requirements. This technology is used for stainless steels (300 and 400 series, titanium, 17-4, 17-7); MP35N (cobalt-chrome steel alloy); and Nitinol. The method can be used for both on-axis (90º to surface) and off-axis (angled to surface) cutting.

A highly focused laser is used to melt a thin sliver of material. While the material is still molten, a 0.02-inch diameter gas jet nozzle that is coaxial with the laser, blows away the molten material. The desired features are produced using this continual cycle of melt, then melt ejection. Distance between the laser and the material needs to be maintained precisely.

The O2 actually serves two purposes – it blows away the molten material and also serves as a heating element, because the heated material reacts with it and also heats up. The heat reaction caused by the presence of O2 adds about 30 to 50 percent more heating energy to the cutting area. The gas assist is a key factor in increasing cut speed and cut quality. Figure 1 illustrates a basic fiber laser cutter with gas assist.

Figure 1. Fiber laser cutter with gas assist

Laser cutting with gas assist produces the highest cut quality and high resolution cut paths, a key focus of makers of medical tube tools and components. Dimensional accuracy is key to measuring cut quality – does the part match the print? Other considerations include surface roughness (better than 12 micro inches) and the absence of thermal damage. Also, in specific reference to shaver blades, the sharpness of the cutting edges are critical.

Cut width can be extremely small with laser cutting technology less than 0.001-inch – and dimensional accuracy is extremely precise, at about +- 0.0005-inch. This accuracy is very useful for producing the jagged teeth used in some cutting tools. Dross or burr left on the underside of the cut (which can become attached and re-solidified) is minimized or eliminated. This significantly reduces the amount of post-processing needed. The recast level layer (a small amount of material that doesn’t get blown away during the process) is less than 0.0005-inch.

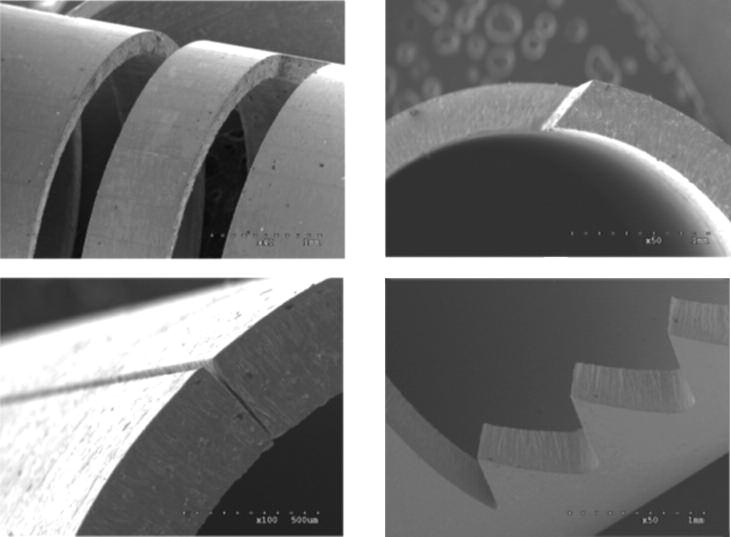

Figure 2 illustrates the typical cut quality with no post processing of features and edges when cutting .01-inch thick stainless steel (304SS) tubing, showing the excellent quality of laser cut faces.

Figure 2. Laser cut quality 304 SS tubing (0.01-inch thick)

Laser cutting compares favorably with other available technologies

Laser cutting’s speed and precision compares favorably with that of the chief competing technology, wire electro discharge machining (EDM). To obtain the same high quality cut as a laser cutting machine, EDM requires up to 4 passes, which slows down processes considerably. On the plus side, EDM allows multiple parts to be processed at once.

The widths of cuts produced by a laser cutter can be as small as 0.001-inch, while EDM results in cut widths around 0.004-0.008 inch. Feature sizes are limited with EDM and sharpness is not as good, compromising cut resolution.

The EDM process is also limited by the fact that it works best with certain geometries, for example tubes with a symmetrical profile. Problems arise if there is a hole in a tube that does not go through both sides. The process is analogous to the ubiquitous cheese cutter that uses a wire to slice through a block of cheese. All is well with a symmetrical, solid shape, but the wire cannot handle any complex geometries. In addition, if the cut geometry requires transition between aqueous wire EDM and the organic solution probe EDM process, a secondary cleaning step is needed.

A final issue is floor space, especially for factories where space is at a premium. A typical EDM machine can be as large as 10 to 12 feet square, while a laser cutting system is just 5 to 6 feet square.

Another competing technology is electro chemical grinding (ECM), which removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged work piece. ECM is a fast cutting method that gets quality similar to EDM. With ECM, the electrolyte used must be disposed of in accordance with OSHA standards as hazardous waste, and some electrolytes produce hexavalent chrome when cutting steels. Finally, ECM’s use of hard tooling makes it much less flexible than laser cutting.

A third available technology is water jet cutting, which uses either a jet of water or a mixture os water and an abrasive substance, to slice into metal at high velocity and pressure. Water jet cutters offer restricted cut geometry: only symmetrical through-features or end cuts are possible using this technology.

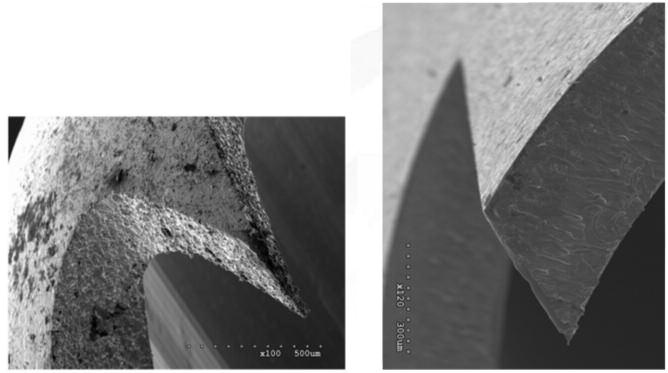

Figure 3 shows a comparison of the cut quality of EDM and laser. Note the smooth sharp edges in the cut made by the fiber laser equipment

Source: Miyachi Unitek Corporation

Wire EDM Laser

Figure 3. Cut quality comparison

New laser technology offers 5-axis motion

The explosion of new non-invasive surgery tools gives rise to some unique and innovative shapes. This in turn requires motion packages that offer a new level of cutting geometry. The ability to keep a part in a machine and make intricate cuts gives designers freedom, enabling them to cut more challenging geometries in one pass.

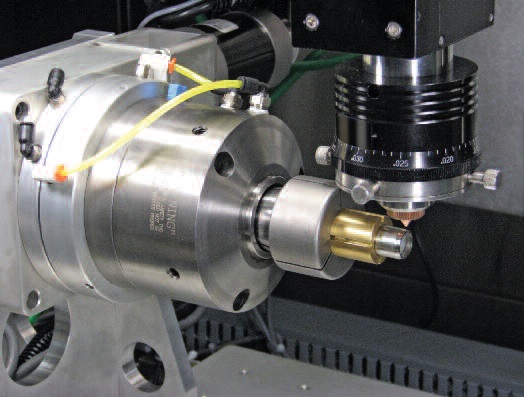

One technology now being offered is a 5-axis laser cutting system offered by Miyachi Unitek (figure 4). The control software controls the laser and the motion together, and the integration of these two aspects provides a rigid structure, free from vibration.

The 5-axis motion consists of 3 linear and 2 rotary axes. The unique set-up allows system engineers great flexibility to choose the best axis configuration for a particular cut, regardless of where they are on the part. Engineers can mix and match and set combinations for maximum process efficiency. For example, designers might place 4 axes on the part and one on the focus head, or switch them around according to the best solution for the application.

Figure 4. 5-Axis Laser Cutting System from Miyachi Unitek

The key to success with laser cutting –system integration

Laser cutting for medical tube tools and components has many benefits, but actually achieving them depends in no small part on successful system integration. Designers need to develop an entire system where the motion, laser, software, and tooling all work properly and are integrated into a whole that supports the desired process flow.

Putting the pieces together can be a challenge, exacerbated by the fact that many integrators do not have a good understanding of the laser cutting tool, and might thus be tempted to rely on the company that makes the laser cutter to integrate the system. When or if there is a problem with the laser, or if changes are needed to adjust to a new product, the integrator is in no position to fix the system.

By contrast, Miyachi Unitek has addressed this issue by expanding in-house laser cutting capabilities and knowledge of the cutting process. While not a cutting laser manufacturer, Miyachi Unitek purchases the laser from an OEM and integrates it into a complete system with motion, software and tooling. Adding laser cutting to its already significant laser welding and marking/engraving capabilities, offers designers a one-stop shop for system integration. This includes running samples of the entire process in-house, ensuring that it does the entire job as specified, and answering in-depth application questions.

Click to view E-zine:International Metalworking News for Asia – Dec issue

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login