FLEXCO will participate in the International Food Machinery & Technology Exhibition (FOOMA JAPAN), held in Tokyo from June 13 to 16, 2017.

This is Flexco’s second participation and collaboration with authorized distributor, Kubo Shokai Co., Ltd at FOOMA JAPAN to bring enhanced and innovative conveyor solutions that effectively meet the global food processing standard and guidelines to its customers and partners in Japan.

The company’s market presence in Japan has been growing since 2012, providing its expertise in light-duty endless splicing and fastener solutions to global and local food processing brands in Japan - including the bakery and confectionery, meat, poultry and seafood industries.

The Japanese food industry is prominent for its top-notch food product quality and immensely high standards of hygiene. Therefore, to enhance the integrity of products produced in Japan, consistent conveyor system maintenance and conformity with food safety standards is deemed necessary to ensure food is served at its best, and to safeguard consumer health.

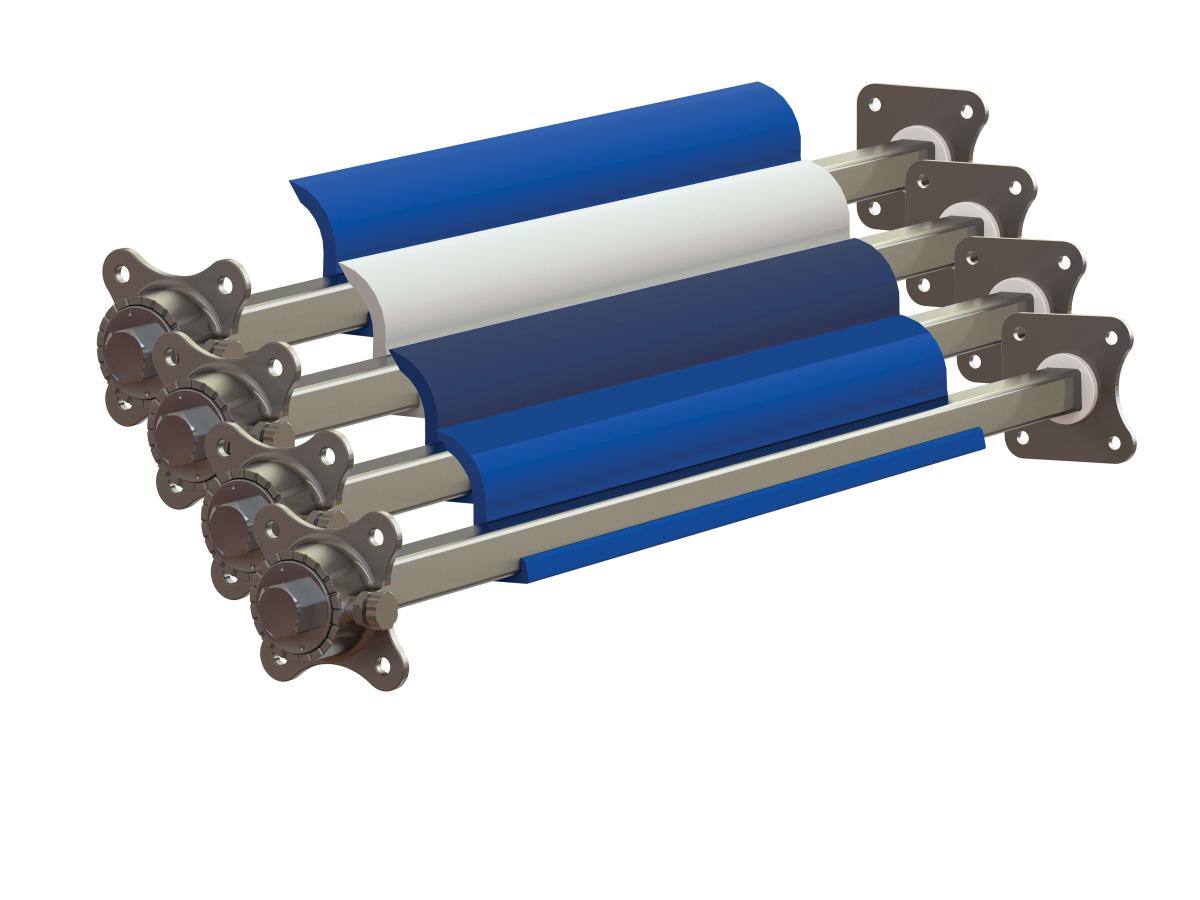

FGP Food Grade Precleaner helps reduce sticky residue or granular bakery ingredients) in a conveyor

FGP Food Grade Precleaner

Responding to industry demands, Flexco introduced the new FGP Food Grade Precleaner to reduce exorbitant sanitation-related costs without compromising food safety standards. At the booth, Flexco will highlight the cleaning efficiency of the FGP Food Grade Precleaner, which helps reduce carryback (sticky food residue or granular bakery ingredients), and discourages bacteria growth on the conveyor, reducing the risk of product contamination.

At the show, the FGP Food Grade Precleaner, which is now available with a metal detectable blade, will be installed on a running conveyor carrying raw food ingredients. For food processing industry, it is important to have a metal detectable blade as many food processing facilities require metal detectable plastics in the food contact zone. In addition, the FGP Food Grade Precleaner is designed to adhere to strict sanitary guidelines that are FDA-approved and USDA-certified for use with meat and poultry, and dairy operations. Flexco representatives onsite will demonstrate how users can assemble and disassemble the FGP Food Grade Precleaner in less than a minute to improve manufacturing efficiencies for cleaning and sanitization procedures. The new metal detectable blade also works on any belt from 100 mm to 1500 mm (4" to 60").

The Novitool® Aero® Splice Press has been enhanced with the exclusive Aero Recipe Management Tool for producing consistent, superior endless splices

Novitool® Aero® Splice Press

Another avant-garde technology recommended for the food processing industry at FOOMA JAPAN 2017 is Flexco’s new and improved Novitool® Aero® Splice Press, which now comes with the exclusive Aero Recipe Management Tool for producing consistent, superior endless splices with ease. The efficient air-cooling system of the Aero Splice Press eliminates the problem of hoses and tanks needed for a water-cooled press, which could easily harbor bacteria, leading to unsanitary environments. “The recent upgrades truly improve the performance of the Aero Press,” said Michelle Graves, product manager at Flexco.

“Flexco is committed to serving the unmet needs of current and potential customers,” said Kizen Sasaki, Japan regional sales manager at Flexco. “We have received a lot of support and interest from brands across the globe and are excited to work closely with our Japanese customers and partners to ensure consumer safety and high-level productivity.”

For more information on how Flexco can maximize your belt conveyor productivity, visit Flexco at FOOMA JAPAN 2017 (Booth 7G-04).

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login