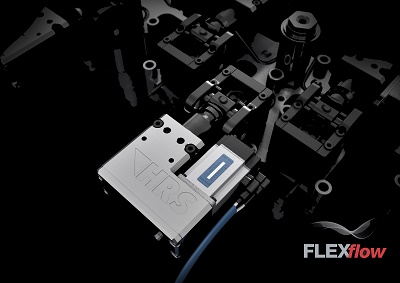

One of the main achievement of hot runner specialist HRSflow is its innovative FLEXflow technology. Launched in 2013, many customers have attested to its advantages in terms of both aesthetical benefits and operational impact. This process, which has been subjected to constant further development, involves a servo-driven valve gate to ensure accurate, easy and flexible control of the pressures and flow rates in cascade injection molding.

At CHINAPLAS 2016, the integration of FLEXflow into the Moldflow simulation software will be demonstrated in public. The system, which has been developed together with Autodesk, provides detailed data for designing plastic parts and injection molds and for the injection molding process as a whole. Moldflow is used to simulate the stepwise opening and closing of the FLEXflow needle valve nozzles to forecast the pressure build-up in the cavity and the required mold clamping force. With the Moldflow filling analysis, it is also possible to determine the opening positions, times and velocities during opening and closing of the valve pins. These data can subsequently be transferred as the basic settings to the FLEXflow control unit, thereby significantly shortening the start-up process for a mold.

The forecasts obtained with the Moldflow analysis were verified through practical tests with a mold for a roof spoiler for a current series-manufactured vehicle. The mold was equipped with a five-fold hot runner system and additional pressure sensors in the cavity. The spoiler, measuring 1,260 mm x 280 mm x 120 mm with a wall thickness of 3.9 mm, is produced by cascade injection molding from a PP/EPDM compound with 20 % talc. The slow, measured filling of the mold was simulated.

The results of these tests confirmed the data previously obtained with the Moldflow analysis. For example, the holding pressure profile in the cavity was significantly more uniform when the FLEXflow system was used, and the required holding pressure was lower than with the conventional process of cascade injection molding that was examined in parallel. As a result, the parts showed far better surface quality and, through the lower stresses, reduced tendency to warpage. The tests also showed that, in the case of the spoiler mold, around 20% less clamping force is needed with FLEXflow than has been necessary with the series-production mold.

Accurately controlled processes result in better quality parts

One of the advantages of the FLEXflow valve gate system is that it enables large-area parts to be produced with high-quality surfaces. Especially in the case of cascade injection molding, the electrically driven needle valve nozzles allow precise and individual opening and closing of the valve pins in coordinated sequences and with selected velocities. As a result, the melt flow in the individual hot runner nozzles and the volume flow in the cavity can be precisely controlled. With the soft opening and closing of the pins, the much feared pressure drop with cascade injection molding and the accompanying pressure drop marks on the part are avoided.

Due to the much enlarged process window, FLEXflow also enables the necessary clamping force and even the part weight to be reduced without any loss of quality. It is, for example, possible with a fivefold FLEXflow hot runner to reduce the thickness of the 1.1 m long lens of a front headlamp from 3 mm to just 1.8 mm – made from injection-molded transparent PC without any flow lines.

With the FLEXflow hot runner system, the individual valve pins can be precisely opened and closed step by step and independently of one another. Depending on the opening or closing step, up to eight pin positions can be defined with an accuracy of up to 10 µm. The settings are made via a controller with which at present up to 16 hot runner nozzles can be individually controlled. In automotive design, the FLEXflow technology brings advantages especially with the injection molding of large-area exterior and interior parts such as spoilers, front ends, instrument panel supports and door trim.

HRSflow

Tel: +86-571 8668 6900

Fax: + 86-571 8668 6901

E-mail: china@hrsflow.com

Website: www.hrsflow.com

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login