A SITUATION when food is rendered free from all types of contaminants such that when eaten no illness will occur, describes food safety. Sources of these contaminants include those of “physical”, “chemical” and “biological” nature which could enter food and when eaten could result in illness. This condition at the processing area is described as loss of food safety. “Physical” contaminants such as broken glass, pieces of wood, stones, metals, other foreign materials in careless situations, could enter into food before this is consumed. In other instances, farm produce can contain “chemicals” such as pesticide and fertilizer residues or chemical residues from cleansing solution and similar contaminants during processing or cooking. Preservatives like sulfites, bromides and the like enter into food.

Entry into food of “microbiological” contaminants like bacteria, viruses, fine worms and other microorganisms harmful to man which when eaten, could result in illness.

Approaches to food safety sustainability

Contaminants can get into food either through cross-contamination due to contact of either “food with food” or “equipment with food” or “people with food”. Thus, food, equipment and people are the major sources of contaminants which can be prevented, reduced, or eliminated to avoid loss of food safety. Approaches towards this end had been developed, adopted, validated and shared on a global scale. These accepted approaches include: a) Implementation of current good manufacturing practices (cGMP); (b) application of sanitation standard operating procedures (SSOP) in the shop-floor; and (c) setting-up of a hazard analysis critical control point (HACCP) plan. These are requirements that food processors and those engaged in food service must learn to organize and employ on a sustainable basis to ensure food safety in their operations.

The need to systematize and standardize the globally employed food safety approaches prompted the International Organization for Standardization (ISO) to develop the “food safety management systems” (FSMS) known as ISO 22000:2005 (Fergemand, J. 2006). To date, its revisions had been completed and its updated title “ISO 22000:2015” had been released for international circulation and use. This is expected to completely replace the ISO 22000: 2005 version by 2018. This FSMS standard promotes a systematic approach to implementation of HACCP plans that ensure food safety while providing a guide for third party inspection of the systems employed (Gatchalian, M.M. and De Leon, S.Y. 2016). This also provides assurance that the integrity of the food chain will be maintained.

Food safety in bottled sugarcane juice

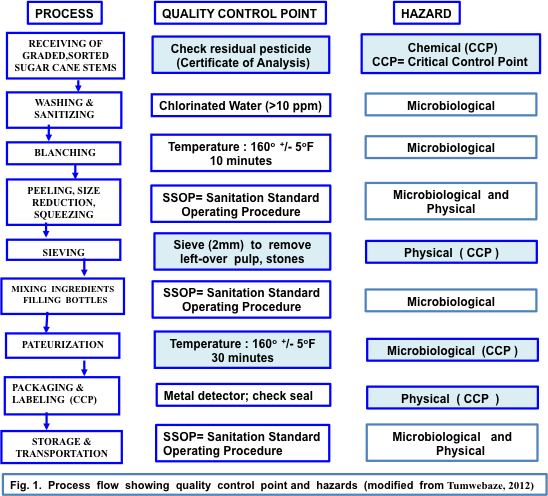

Figure 1 presents an example of a process flow for a non-alcoholic, heat-processed beverage where internationally approved approaches to food safety are employed. Column 1 in Figure 1 shows the steps for the Process Flow of bottled sugarcane juice where column 2 presents the Quality Control Point (QCP) corresponding to each step, while Column 3 Hazard identifies the potential contaminants. In food and beverage processing, it is very important that the process steps be first standardized under strictly followed sanitary conditions and environment for the total operation. It is expected that specification limits are set for each step for effective replication of every production batch. These are also important requirements to ensure that current good manufacturing practices (cGMP) are properly observed, especially since cGMP is the correct starting point of any food safety program.

Quality Control Point (QCP) and Critical Control Point (CCP). The process flow in Figure 1 column 1 starts with “receiving graded, sorted sugarcane stems” (raw materials) and ends with “storage and transportation” of finished products. Every step is expected to follow the approved “specification or control limits” developed after the completion of product and process standardization. The “control limits” in each process step is necessary to ensure consistency of finished product quality from one production batch to the next. Besides, it is imperative that control of every process step should first be in place before food safety requirements can be imposed. For example in Figure 1, the first process step “receiving graded, sorted sugarcane stems”, has the corresponding QCP “check pesticide residue” the absence of which is supported by the “certificate of analysis”. Column 3 identifies the potential hazards present in the materials undergoing each process step. Thus, step 1 (“receiving graded, sorted sugarcane stems”) in column 1 corresponds in column 3 to “chemical” hazard in connection with possible “insecticide residue” contained in the raw material. This is identified as a “critical control point” (CCP) since it is only at this step and at no other step in the total process can this “chemical” hazard be prevented through the supplier’s “certificate of analysis” validated by the Processor.

The same principle of hazard prevention, reduction or elimination could only happen at the “Sieving” step where physical hazards like stone, glass, wood can be removed. This step is thus, identified as a CCP. Use of “metal detector” is also the only step which locates then have metals eliminated, as physical hazards. The pasteurization step which heats the juice at 160+/- 5oF for 30 minutes ensures destruction of pathogenic microorganisms and there is no other step after this that elimination of microorganisms can be done, making this a CCP. There are four CCPs in the total process. Identification of hazards in a specific food process is the first of seven principles in Hazard Analysis Critical Control Point (HACCP) plan which is discussed in detail in published food safety programs (NSHA, 2011).

Sanitation standard operating procedure (SSOP). Figure 1, column 1 shows another process step, “peeling, size reduction, squeezing” giving high potentials for the raw materials to be contaminated by food handlers and equipment contact. Thus, shown in column 2 (QCP) and corresponding to this process step, is the acronym “SSOP” or Sanitation Standard Operating Procedure. The SSOP have eight conditions pertaining to sanitation requirements that can prevent entry of microbiological and physical contaminants at a given process step. If SSOP is in place, then this particular step is not a CCP since the SSOP will take care of food safety protection. Following all the requirements under QCP in a standardized process, it can be expected that identified potential hazards would be prevented, reduced or eliminated through effective SSOP or CCP implementation.

Pre-requisites to a sustainable food safety program

It takes good leadership and well-trained engaged employees to sustain a food safety program (Gatchalian, M.M. 2007). Of the 6-Ms (Manpower, Materials, Methods, Machines, Measurement, Mother Earth) that contribute to a quality program, it is Manpower that dictates how all the other Ms can be utilized in the operations. Figure 2 presents the important role that manpower plays in sustaining a food safety program. Full management support for all quality efforts including the development of a food safety program rests heavily on organizational leadership. Unless a policy that states categorically that top Management fully supports all efforts towards development, implementation and continual improvement of quality and food safety programs, there will be great difficulty for these efforts to succeed.

Workplace cooperation towards employee engagement. The culture-based approach to total quality management (TQM) with acronym “SUGOD” ( Survey, Unite, Grow, Operationalize, Develop) is both a road map and framework to guide an organization in their quest for food safety and quality sustainability (Gatchalian, M.M. 2012). “SUGOD” is a Filipino word meaning “move-on together” which propels, in a compassionate culture, the quest to achieve a common goal. For this approach, “workplace cooperation” as shown in Figure 2, provides both the process and structure towards “employee engagement” necessary to quickly respond to weaknesses of the organization identified at the Survey Phase.

After the SURVEY Phase, everyone especially top management, begins to realize the need to UNITE through a guided strategic planning program where the importance of

capability building is agreed upon. At the GROW phase training plans are executed and immediately linked with improvements necessary in plant operations at the OPERATIONALIZE Phase. The DEVELOP approach Phase uses all information from the first four “SUGO” Phases to level-up in the next cycle of “SUGOD”. Continual improvement company-wide is achieved at every cycle where everyone is involved with having to contribute to the Company’s directions especially relative to the realization of the quality and food safety program. The proper application of cGMP, QCP, SSOP by engaged employees, ensures that the HACCP plan will be made to work, thus preparing the Company towards a higher level of Food Safety Program following International standards like the ISO 22000:2015.

*Dr Miflora M. Gatchalian is the CEO of Quality Partners Company, Ltd in the Philippines and a member of the editorial board of FoodPacific Manufacturing Journal

References

Færgemand, Jacob. 2006. The ISO 22000 series: Global standards for safe food supply chains. In ISO Management Systems. May-June 2006, Special report. International Organization for Standardization. (http://www.iso.org/iso/iso22000_ims_08-3.pdf )

Gatchalian, M. M. 2005. ISO 22000- Food Safety Management Systems: The Tool to Ensure Integrity of the Food Supply Chain. Proceedings. 11th APQO Conference. Hanoi, Vietnam. October 2005.

Gatchalian, M.M. 2007.Quality Employees: Their Role in Promoting and Sustaining Food Safety. Keynote Speech Proceedings.13th Asia Pacific Quality Conference and 7th Shanghai Association for Quality Congress October 18- 20, 2007, Shanghai, China.

Gatchalian, M.M. 2012. Phases of Total Quality Towards Competitiveness Improvement. Keynote Speech. Proceedings. VII International Quality Managers Forum. June 27-29, 2012, Almaty, Kazakhstan.

Gatchalian, M. M. and De Leon, S.Y. 2016. Introduction to Food Technology Focus on Carbohydrate-rich Food. Vol. 1, 2nd Edition. Merriam - Webster Publishers. In press.

NSHA, 2011. Hazard Analysis and Critical Control Point Training Curriculum. 5th Edition

Tumwebaze, Joel. 2012. Posted in nutrientdigester.blogspot.com

Adidas Yeezy shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login