Functional integration, the combination of various colours and materials and large-volume production are now made possible with the latest series of all-electric injection moulding machines. Many of the innovations have enabled customers to upgrade their products’ quality and increase their efficiency to meet growing competition.

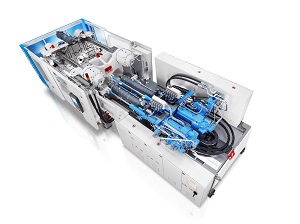

KraussMaffei launched the latest variants of its injection moulding machines at NPE 2015. With a total of five variants of the GX twin-platen injection moulding machine, KraussMaffei is completing its portfolio of injection moulding machines in the medium clamping force range. The GXH, GXL, GXV, GXW and GXZ provide ideal conditions for multi-component injection moulding.

"With the Multinject technology based on the CX, GX, and MX series, we cover small, mid-size, and large clamping force options from 350 to 55,000 kN," according to Paul Caprio, President of the KraussMaffei Corporation in the USA.

Depending on requirements and product, the customer can select suitable positioning of the injection units and the optional turntable. The H in GXH stands for the symbolic arrangement of two or more injection units in parallel. Using the horizontal arrangement, the melt is guided directly into the respective mould-half. This way, so-called dead corners in the hot runner are reduced.

Additional advantages of injection units arranged in parallel are the simplified mould design and space-saving design of the entire machine. Typical end applications of GXH are found in the manufacture of technical and optical vehicle components. 2-component screw-cap closures for the packaging industry can also be produced efficiently. Advantages of the GearX locking mechanism and the GuideX guide shoe developed by KraussMaffei are apparent in fast cycle times with minimal energy consumption.

The L in GXL on the other hand stands for the lateral horizontal positioning of the second injection unit. Thanks to the modular design of the GX series, small and large shot weights can be implemented. Third in the group is the new GXV with vertical positioning of the second injection unit, which allows access to the main injection unit. The V injection unit can be moved entirely out of the clamping unit area for the mold change to substantially improve accessibility.

The distinguishing feature of the GXZ is a piggyback structure with parked position. When exchanging the main injection unit, this results in shorter times for changing the plasticising unit. The GXW stands for the SpinForm swivel plate technology and offers twice the output (more cavities). This way, large and complex components with functional integration can be produced almost effortlessly.

Wide processing possibilities

The multi-component injection moulding machines of the KraussMaffei GX series enable a wide processing spectrum. Not only two, but up to four different components can be processed and combined. "The requirements for multifunctional components consisting of three or more materials continue to increase. The modular configuration of additional injection units make 3- or 4-colour machines an easy possibility. All units are controlled centrally by the KraussMaffei MC6 control system," Mr. Caprio added.

KraussMaffei has been producing premium quality injection moulding machines for logistics products. For example, its GX 650-8100 demonstrated efficient production of transport crates, thereby emphasizing the efficiency of the GX Series for high-speed applications. At another show, Plast 2015, the company stressed the advantages of its GX 650-8100.

"In Italy and North Africa we are seeing increasing production demand for logistics products, for example transport containers and crates for vegetables, fruit and food such as fish, meat or bread," said Andrea Bottelli, Head of KraussMaffei Group Italia s.r.l. The GX Series is ideally suited to ensuring the shortest possible cycle times for transport and logistics packaging. GX 650-8100, for instance, can produce a stackable polypropylene transport crate with integrated handles and a shot weight of 500 g in a cycle time of approximately 8 seconds. The machine contains, as a standard feature, a chute which is also suitable for wide conveyors. The finished components can therefore be demoulded either with or without an automation solution. The height of the machine was increased by 150 mm so that large free-falling parts can also be transported.

The combination of the fastest and most efficient two-platen machine on the market, a proven plasticising unit and state-of-the-art drive technology makes injection moulding orders for processors more profitable. The innovations of the GearX locking device and the stable GuideX guide shoe also ensure quick locking and high part quality with minimum energy consumption.

The machine is equipped with an APC (adaptive process control) machine function from KraussMaffei. This function can be used to immediately compensate for fluctuations in the manufacturing process during injection moulding. The APC function adjusts the changeover point and the holding pressure profile in each cycle to the current melt viscosity and current flow resistance in the mould. This makes it possible to compensate for deviations in the same shot. This leads to significantly lower fluctuations in the part weight. In this way, fluctuations in the manufacturing process triggered by external factors such as changing temperatures, climate conditions or batches can reliably be compensated for.

GX Series machines are predestined for high-speed applications.

Answering the call for size and volume

KraussMaffei’s range of injection moulding machines has been expanded as part of the company’s response to market demand. It has installed MXH 3200 – 101.000/101.000 for a customer in Switzerland, the largest ever to be installed in terms of clamping force and shot weight. The machine began production in late 2014 manufacturing large-volume pipe fittings with a diameter of up to 500 mm.

MXH 3200 – 101.000/101.000 has a clamping force of 32,000 kN, a maximum shot weight of 120 kg, a screw diameter of 2 x 265 mm. The products made on the machine are just as large and complex—pipe fittings with a diameter of up to 500 mm and a weight of up to 120 kg. These are used as connecting pieces for the public water supply. An IR KR500 L340 industrial robot ensures reliable handling of the pipe fittings, which can weigh up to 120 kg. This is another record because—with a maximum payload of up to 340 kg—this is the largest industrial robot that has ever been installed on an injection moulding machine

Yet this large machine must do more than just produce large components with high quality. The customer also wants high flexibility with regard to material, size and geometry when producing the pipe fittings. For this reason, the large machine is equipped with two injection units that can be interconnected as needed. Furthermore, each injection unit can be operated independently. This results in high application-specific flexibility in the process control. The adapter modules of the plasticising unit provide additional flexibility in the production of pipe fittings. BluePower Servo Drive Technology from KraussMaffei supports an energy-efficient manufacturing process. For the energy-related optimisation of hydraulic drives, it uses the high dynamics of servomotors to adapt the rotational speed of the hydraulic system pump to constantly adapt to the actual requirements. The same dynamics are used to reduce idling losses to almost zero by reducing the speed, such as during cooling times and during demoulding. As a result, the energy consumption of the machine can be significantly reduced.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login