For several years now job shops have grown familiar to using 2D laser cutting for higher productivity in the sheet metal processing industry. And 2D laser cutting is one of the areas in which TRUMPF is once more demonstrating its technological leadership, with new features and the new TruLaser 5030 fiber pointing the way to the 2D laser cutting of the future.

According to the company, its new generation of laser cutting technology promises to win you over with its intelligent software features, smart functions, 8 kilowatts of laser power and much more. During last year's EuroBLECH, TRUMPF showcased the first 2D laser cutting machine to feature an 8 kilowatt TruDisk laser. The company open a new chapter in the use of solid-state lasers for sheet metal, with the increased laser power promising to significantly boost product ivity in the processing of medium and thicker sheets.

High quality is guaranteed thanks to the BrightLine fiber, CoolLine and improved PierceLine functions. CoolLine is a new feature for solid-state lasers and stabilises the steel cutting process by employing targeted cooling. The result is greater material tolerance, for instance for lower quality mild steel. It also allows for much more intricate parts and a tighter sheet layout. PierceLine is the name for an improved piercing process, enabling even smaller contours while significantly boosting speed. As a high-productivity, all-purpose machine, the new TruLaser 5030 fiber processes complex contours and thin sheets at minimum cost per part. And thanks to the innovations mentioned above, it also assures maximum productivity and high-quality results in the thicker sheet range.

Smart – efficiency, process reliability, and economy

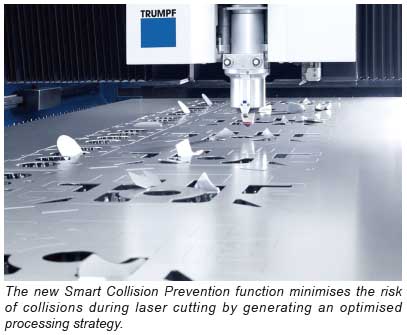

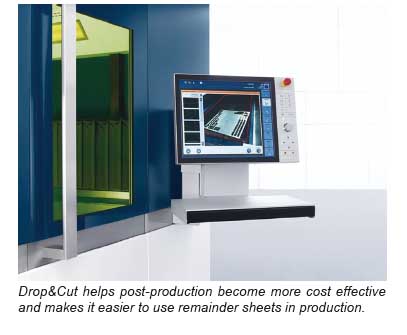

Two more new functions, Smart Collision Prevention and Drop&Cut, make TRUMPF 2D laser cutting machines even more efficient and guarantee more reliable processing. Both features are available for the new TruLaser 5030 fiber as well as all latest machines in the TruLaser Series 3000 and 5000.

Smart collision prevention minimises the risk of collisions during laser cutting. To do this, the smart function analyses the whole process and generates an optimised processing strategy that factors in any tipping in the parts cut free. This minimises downtime and waiting times caused by collisions. Generally, Smart Collision Prevention is able to operate without having to place microjoints. Gone too is the need to watch over the cutting process in order to prevent collisions – time that the machine operator can spend on other tasks. When coupled with the smart nozzle automation function, with its integrated nozzle inspection feature for guaranteeing high nozzle quality, and the optimised PierceLine piercing process, Smart Collision Prevention assures maximum process reliability for the TruLaser 5030 fiber. This substantially expands machine capacity while reducing the need for consumables.

The new Drop&Cut feature helps repeat production become more cost-effective, and makes it extremely easy to use residual sheets for production. Operators are presented with a live image of the machine interior on the control unit's user interface. They can then click or tap to virtually drag the programmed contour onto the sheet and place it as desired before cutting begins. With the new TruLaser 5030 fiber, this process is conveniently managed from a new and ergonomic 19-inch control panel that can be adjusted to any height.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login