FOR the first time, the company will exhibit highly versatile equipment for the packaging of bakery and confectionery products in the Middle East, Africa and Indian Sub-Continent, helping manufacturers to efficiently adapt to changing market needs.

“Whether manufacturers need a stand-alone machine or an entire packaging system, Bosch’s complete range of equipment and extensive technical knowledge can help meet the increasing demands of the food and non-food markets in Africa and the Middle East,” said Mazen Touban, general manager, Bosch Packaging Technology office in Egypt. “With a regional office in Cairo, Egypt, our customers benefit from a local presence backed by an international knowledge network and world-class expertise to meet the specific challenges of this market.”

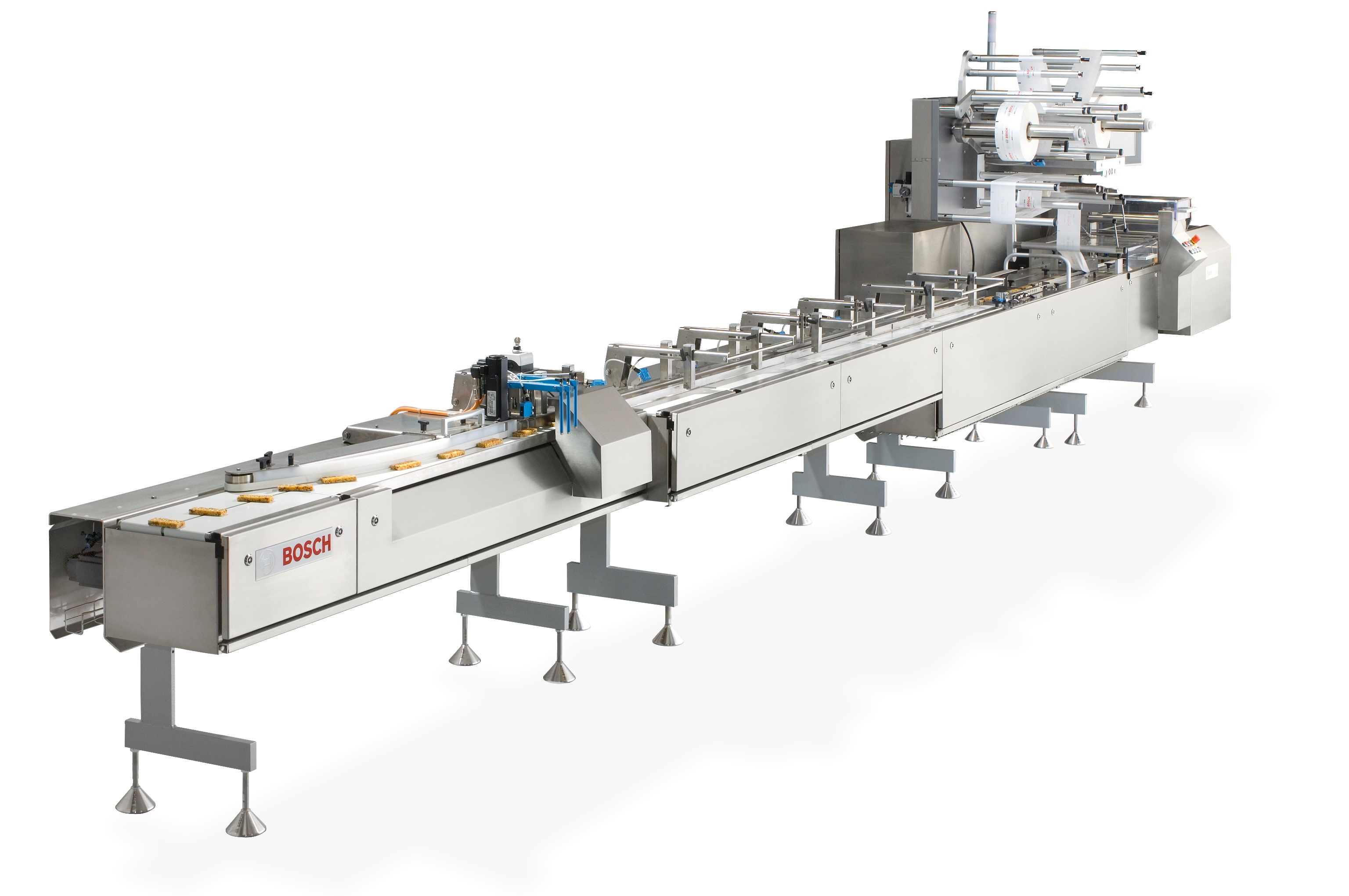

Efficient feeding for versatile horizontal flow wrappers

On display is the Pack Feeder 4 infeed system in combination with the Pack 401 horizontal flow wrapper for flexible packaging of bakery and confectionery products. It is a low-pressure feeding system that gently handles delicate items such as biscuits, chocolate, cakes and bar-type products. Sophisticated product inspection on the Pack Feeder 4 detects and rejects misaligned products to maximize productivity and minimise downtime. Depending on the product, the feeding system can be equipped with side belts for optimal product positioning and stability, enhancing consistent and efficient packaging.

The Pack 401 horizontal flow wrapper can be integrated with a wide range of semi- to fully-automated feeding solutions, including the Pack Feeder 4. Developed for full automation, the machine now features a narrower cutting head, enabling higher packaging speeds for heat seal applications up to 800 products per minute. It is optionally available with features such as automatic film splicing and tracking, as well as product inspection and rejection technology. The design allows easy changeovers for different product and packaging formats. Part of Bosch’s Pack series, the Pack 401 is just one model from the company′s comprehensive portfolio of horizontal flow wrappers available to customers.

High volume production of confectionery products

Bosch’s product portfolio includes specialised equipment for the production of confectionery items, such as hard and soft candy, toffee, jelly and chewing gum, as well as chocolate, fruit, cereal, energy and protein bars. With the recently launched slab former WRF 600 Flex bar manufacturers can minimize or eliminate the trim when processing masses for cereal, candy, protein and fruit bars. The machine enables width changes without production stoppages, maximising uptime and output. No other equipment of its kind currently available on the market offers this capability.

Vertical packaging portfolio for versatile solutions

The vertical packaging portfolio comprises highly adaptable and scalable equipment covering a wide range of products, including dry, free-flowing goods. The highly flexible SVC and SVE platforms are the first choice for manufacturers who need to switch between different bag styles, with multiple reclosure and opening features as well as for manufactures running block-buster products on high speed lines.

For customised solutions dedicated to the packaging of sensitive dry and free-flowing products such as coffee, Bosch offers the machine family PME. Due to its modular design, the PME stands for high flexibility and premium quality because either soft or vacuum bags with different head closures can be produced on one machine. In addition, this vertical package maker can be equipped individually with Bosch product protection systems such as inside and outside valves and their respective applicators. The portfolio is completed by fully integrable equipment including hygienic auger fillers, and checkweighers.

Hygienic solutions for liquid and viscous food

Bosch offers a wide range of solutions for the packaging of liquid and viscous foods, including equipment dedicated to sensitive products such as dairy and baby food. The highly hygienic technologies allow the thermoforming, filling and closing of cups in various shapes, the filling and sealing of pre-made cups and bottles as well the blow-moulding and filling of PET bottles.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login