SNACKING is more than ever part of today's consumer, whose on-the-go lifestyle means fewer meals at the dining table and more eating on the move or away from the home setting. This type of consumption has lead to concern about the quality of foods and how they can contribute to the development of serious diseases, such as cardiovascular disease and obesity, owing to high caloric, fat and sodium content. Healthy snack alternatives are being developed in response to these concerns. The snack industry is reformulating to remove trans fatty acids [turn to page 24 for a briefing on dietary fats -Editor], reduce salt and replace with other flavour combinations, and to eliminate preservatives. Hundred-gram portion snacks still continue to be introduced, although the premium price for these smaller packages may put off economy-conscious snackers. Processing technology has also been developed as alternatives to traditional frying in order to reduce fat content. Still other systems use computer-operated systems to precisely control frying or baking time and reduce the formation of acrylamide, a suspected human carcinogen.

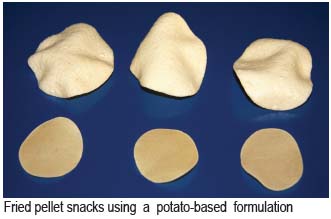

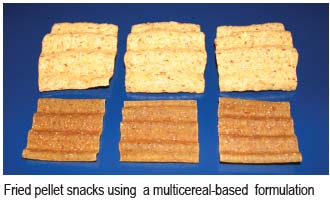

Reduction of acrylamide Browning during baking, frying or deep-frying will produce acrylamide, and over-cooking may produce large amounts of this carcinogen, which was accidentally discovered by Swedish scientists in April 2002. Whilst the mechanism for acrylamide formation has not yet been fully established, one theory is that it is a by-product of the Maillard reaction, when asparagines and reducing sugars or reactive carbonyls react to form acrylamide. What has been established is that acrylamide levels seem to increase as food is heated at temperatures above 120°C (248°F) for longer periods of time, explains Pavan's New Products manager Luisito Virtucio. Pavan Group develops processing systems and technologies for pasta, noodles and extruded snacks. In line with the company's R&D services, Virtucio conducted tests on how to reduce acrylamide in fried pellet snacks using a potato-based formulation and a cold-extrusion process with an F-model extruder, as well as a multicereal-based formulation and an extrusion cooking process with a G-model extruder. In collaboration with Novozymes, Pavan studied the effect of Acrylaway on the extruded snack pellets. Acrylaway is a commercial asparaginase from Novozymes that can effectively reduce acrylamide in dough-based products. "Acrylaway added to the dough can reduce acrylamide content of fried pellets from dough by more that 65% or way below 100ppb during short frying time, and more than 94% during long frying time," Virtucio said. Fried snacks from dried pellets also show lower acrylamide content of 200-300 μg/g or ppb, compared to snacks from wet-fried extruded product, which had about 1400-1500 μg/g.

"This is most probably due to the much longer frying time of about 45 to 60 seconds needed for wet-fried extruded products, to evaporate excess water, so as to have a crunchy texture," Virtucio explained. In comparison, frying time for snack pellets can be in the range of about 10 seconds for the potato-based formulation and about 15 seconds for the cereal-based formulation. Precision extrusion and frying Up to 450 kg (900 pounds) per hour of twist/curl/collet snacks can be automatically formed on the KoEx friction disk extruders from Heat and Control from de-germed corn grits, polished rice grits, or other lentils and peas for frying or baking. Continuous variable adjustment of the extrusion plate gap and speeds of the feed screw and friction disk precisely maintain product specifications. An electrically heated extrusion barrel maintains optimal extrusion conditAir Max 90 NS GPX

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login