THE new 320t/24h flourmill of South Amman Mills is Jordan's most advanced facility of its kind. The smooth handling of the project and the start-up of the plant ahead of schedule are, amongst other things, the result of using a novel production principle. For the first time ever, specialists applied a new principle in implementing the flour mill project of South Amman Mills, in which all the processes are handled on the basis of a totally synchronised plan. "Our internal experiences with production control and monitoring based on this standardised process have been excellent," explains Hans Tschudin, head of the international installation department of the Grain Processing Division at Bühler AG. "Now we have applied this principle for the first time also in the implementation phase of a customer project - that is, during installation and start-up of a plant. And the result is absolutely overwhelming: In close co-operation with the customer, we completed the mill project of South Amman Mills four weeks ahead of schedule. This enabled our customer to start production four weeks earlier, which translates into genuine added value for them." Synchronised processes The new principle - which is called "Autobahn" or "Highway" at Bühler - supports the chief installation supervisor and produces transparency throughout the installation phase. "The procedure is simple. Weekly meetings are held with the customer at their local site. On the basis of the continuously updated lists and charts, the headway that the project is making is discussed. Problems can be identified and any required corrective action can be discussed and immediately taken. This procedure gives the customer full transparency and makes them a true partner of ours," explains Mr Tschudin. At Bühler, the principle refers to the continuous monitoring of a project and the ongoing adjustment to changes or unforeseen challenges. At regular meetings, the current status of a project is discussed on the basis of drawings and diagrams. If any deviations from the target state are identified, corrective action is immediately discussed and taken. Initially only practiced in-house, individual business units have now started applying this simple yet effective principle as a "Customer Highway" at local customer sites during the implementation phase of a project, and the principle has proven its worth in the everyday production life of the Bühler business units. For the South Amman Mills project, the basis for the weekly stocktaking meetings is provided by standardised lists and charts related to materials, supplies, personnel, and other items, in addition to organisation charts and schedules. "The crucial point is to ensure that the lists and charts are always meticulously updated," says Mr Tschudin.

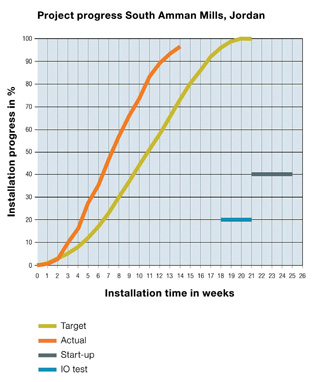

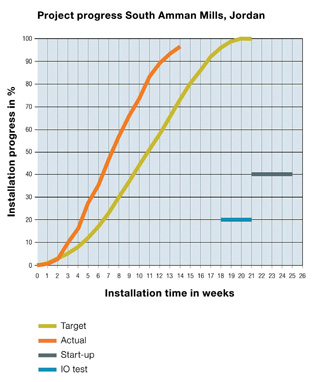

What is most impressive for customers is arguably to see the so-called "progress chart". It shows as a result of all the individual lists and charts the progress that the project is actually making in comparison to the expected progress. The result of the individual meetings is carefully documented. This allows detailed debriefing once a customer project has been completed. "This enables us to identify any existing potential for improvement," Mr Tschudin adds. New flour mill constructed in Amman As a pilot project for applying the new "Customer Highway" approach, the Bühler Grain Milling Business Unit chose the construction of the new Gulf Industrial Development flourmill in the Jordanian capital. "We selected this project because the expansion of the South Amman Mills facility is a mid-size grain mill based on very high engineering standards for an Arabic country. Moreover, the customer was responsible for supplying the building and the infrastructure and for providing the local installation crews. Installation of the pl

Zoom Kobe 1 Protro THE new 320t/24h flourmill of South Amman Mills is Jordan's most advanced facility of its kind. The smooth handling of the project and the start-up of the plant ahead of schedule are, amongst other things, the result of using a novel production principle. For the first time ever, specialists applied a new principle in implementing the flour mill project of South Amman Mills, in which all the processes are handled on the basis of a totally synchronised plan. "Our internal experiences with production control and monitoring based on this standardised process have been excellent," explains Hans Tschudin, head of the international installation department of the Grain Processing Division at Bühler AG. "Now we have applied this principle for the first time also in the implementation phase of a customer project - that is, during installation and start-up of a plant. And the result is absolutely overwhelming: In close co-operation with the customer, we completed the mill project of South Amman Mills four weeks ahead of schedule. This enabled our customer to start production four weeks earlier, which translates into genuine added value for them." Synchronised processes The new principle - which is called "Autobahn" or "Highway" at Bühler - supports the chief installation supervisor and produces transparency throughout the installation phase. "The procedure is simple. Weekly meetings are held with the customer at their local site. On the basis of the continuously updated lists and charts, the headway that the project is making is discussed. Problems can be identified and any required corrective action can be discussed and immediately taken. This procedure gives the customer full transparency and makes them a true partner of ours," explains Mr Tschudin. At Bühler, the principle refers to the continuous monitoring of a project and the ongoing adjustment to changes or unforeseen challenges. At regular meetings, the current status of a project is discussed on the basis of drawings and diagrams. If any deviations from the target state are identified, corrective action is immediately discussed and taken. Initially only practiced in-house, individual business units have now started applying this simple yet effective principle as a "Customer Highway" at local customer sites during the implementation phase of a project, and the principle has proven its worth in the everyday production life of the Bühler business units. For the South Amman Mills project, the basis for the weekly stocktaking meetings is provided by standardised lists and charts related to materials, supplies, personnel, and other items, in addition to organisation charts and schedules. "The crucial point is to ensure that the lists and charts are always meticulously updated," says Mr Tschudin.

THE new 320t/24h flourmill of South Amman Mills is Jordan's most advanced facility of its kind. The smooth handling of the project and the start-up of the plant ahead of schedule are, amongst other things, the result of using a novel production principle. For the first time ever, specialists applied a new principle in implementing the flour mill project of South Amman Mills, in which all the processes are handled on the basis of a totally synchronised plan. "Our internal experiences with production control and monitoring based on this standardised process have been excellent," explains Hans Tschudin, head of the international installation department of the Grain Processing Division at Bühler AG. "Now we have applied this principle for the first time also in the implementation phase of a customer project - that is, during installation and start-up of a plant. And the result is absolutely overwhelming: In close co-operation with the customer, we completed the mill project of South Amman Mills four weeks ahead of schedule. This enabled our customer to start production four weeks earlier, which translates into genuine added value for them." Synchronised processes The new principle - which is called "Autobahn" or "Highway" at Bühler - supports the chief installation supervisor and produces transparency throughout the installation phase. "The procedure is simple. Weekly meetings are held with the customer at their local site. On the basis of the continuously updated lists and charts, the headway that the project is making is discussed. Problems can be identified and any required corrective action can be discussed and immediately taken. This procedure gives the customer full transparency and makes them a true partner of ours," explains Mr Tschudin. At Bühler, the principle refers to the continuous monitoring of a project and the ongoing adjustment to changes or unforeseen challenges. At regular meetings, the current status of a project is discussed on the basis of drawings and diagrams. If any deviations from the target state are identified, corrective action is immediately discussed and taken. Initially only practiced in-house, individual business units have now started applying this simple yet effective principle as a "Customer Highway" at local customer sites during the implementation phase of a project, and the principle has proven its worth in the everyday production life of the Bühler business units. For the South Amman Mills project, the basis for the weekly stocktaking meetings is provided by standardised lists and charts related to materials, supplies, personnel, and other items, in addition to organisation charts and schedules. "The crucial point is to ensure that the lists and charts are always meticulously updated," says Mr Tschudin.  What is most impressive for customers is arguably to see the so-called "progress chart". It shows as a result of all the individual lists and charts the progress that the project is actually making in comparison to the expected progress. The result of the individual meetings is carefully documented. This allows detailed debriefing once a customer project has been completed. "This enables us to identify any existing potential for improvement," Mr Tschudin adds. New flour mill constructed in Amman As a pilot project for applying the new "Customer Highway" approach, the Bühler Grain Milling Business Unit chose the construction of the new Gulf Industrial Development flourmill in the Jordanian capital. "We selected this project because the expansion of the South Amman Mills facility is a mid-size grain mill based on very high engineering standards for an Arabic country. Moreover, the customer was responsible for supplying the building and the infrastructure and for providing the local installation crews. Installation of the plZoom Kobe 1 Protro

What is most impressive for customers is arguably to see the so-called "progress chart". It shows as a result of all the individual lists and charts the progress that the project is actually making in comparison to the expected progress. The result of the individual meetings is carefully documented. This allows detailed debriefing once a customer project has been completed. "This enables us to identify any existing potential for improvement," Mr Tschudin adds. New flour mill constructed in Amman As a pilot project for applying the new "Customer Highway" approach, the Bühler Grain Milling Business Unit chose the construction of the new Gulf Industrial Development flourmill in the Jordanian capital. "We selected this project because the expansion of the South Amman Mills facility is a mid-size grain mill based on very high engineering standards for an Arabic country. Moreover, the customer was responsible for supplying the building and the infrastructure and for providing the local installation crews. Installation of the plZoom Kobe 1 Protro

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login