EVER think about how they make those slices so uniformly thin in that bag of Lay's potato chips? Or did you ever wonder how McDonald's minces the tonnes and tonnes of ground beef it needs for the millions of burgers it sells? And how about that smooth, organic soymilk in your latte-how come it's so smooth and creamy?

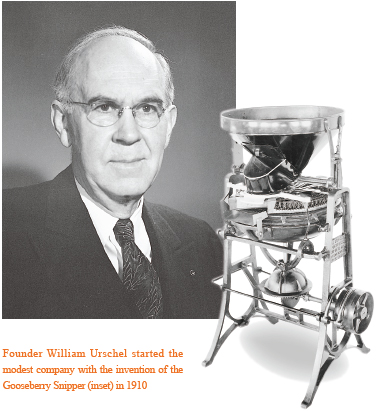

Part of the answer lies in a company that is celebrating a hundred years of cutting and comminuting expertise this year. And whilst this company may not be a household name for the average consumer, for many in the industry it is a well-known and respected one: Urschel Laboratories Inc., known worldwide for precision-engineered size reduction equipment. 'Size reduction' is the catchall term Urschel gives to the dicing, milling and mincing machines that the company has been designing and manufacturing since 1910. It all started when William Urschel designed the Gooseberry Snipper a hundred years ago to remove the stem and blossom ends from gooseberries. This mechanical triumph signalled the start of a small company in Valparaiso, Indiana, USA, originally called the Urschel Gooseberry Snipper Factory, which would later become Urschel Laboratories. The company, to this day, is still owned and operated by direct descendants of William Urschel, including members of the third generation like Bob Urschel, the current president/CEO of the company. "The company has always been an extension of our family," reveals Bob Urschel, adding that parts of the original building where his grandfather set up his company are still in existence today. "At first, the only employees were William and his wife, Ruth. Their house was next door, and, as William did not have any lighting in the shop, Ruth would pass a light bulb from her kitchen to the shop as needed," he recounts. "William's passion was inventing. Innovation is something that has remained a driving force for this company. His creative spirit and ability to look at something from an all encompassing perspective have helped fuel the company's ongoing success," says Bob Urschel, who has worked for four decades at the firm. Passion for precision That passion didn't skip a generation, says EVP of Manufacturing Dan Urschel, another member of the third generation. "My dad, Joe Urschel, and his brothers, Gerald and Kenneth Urschel, picked up where my grandfather left off in many ways. Their childhood was spent, unlike most kids, actually playing at my grandfather's machine shop. No one was ever hurt, my dad said, and they learned all about machine tools, foundry patterns, and all facets of the manufacturing process," he relates.

Part of the answer lies in a company that is celebrating a hundred years of cutting and comminuting expertise this year. And whilst this company may not be a household name for the average consumer, for many in the industry it is a well-known and respected one: Urschel Laboratories Inc., known worldwide for precision-engineered size reduction equipment. 'Size reduction' is the catchall term Urschel gives to the dicing, milling and mincing machines that the company has been designing and manufacturing since 1910. It all started when William Urschel designed the Gooseberry Snipper a hundred years ago to remove the stem and blossom ends from gooseberries. This mechanical triumph signalled the start of a small company in Valparaiso, Indiana, USA, originally called the Urschel Gooseberry Snipper Factory, which would later become Urschel Laboratories. The company, to this day, is still owned and operated by direct descendants of William Urschel, including members of the third generation like Bob Urschel, the current president/CEO of the company. "The company has always been an extension of our family," reveals Bob Urschel, adding that parts of the original building where his grandfather set up his company are still in existence today. "At first, the only employees were William and his wife, Ruth. Their house was next door, and, as William did not have any lighting in the shop, Ruth would pass a light bulb from her kitchen to the shop as needed," he recounts. "William's passion was inventing. Innovation is something that has remained a driving force for this company. His creative spirit and ability to look at something from an all encompassing perspective have helped fuel the company's ongoing success," says Bob Urschel, who has worked for four decades at the firm. Passion for precision That passion didn't skip a generation, says EVP of Manufacturing Dan Urschel, another member of the third generation. "My dad, Joe Urschel, and his brothers, Gerald and Kenneth Urschel, picked up where my grandfather left off in many ways. Their childhood was spent, unlike most kids, actually playing at my grandfather's machine shop. No one was ever hurt, my dad said, and they learned all about machine tools, foundry patterns, and all facets of the manufacturing process," he relates.  "As adults, Joe and Gerald began working full time at Urschel. Amongst their many accomplishments, Joe is credited with developing and patenting the first slicer that used centrifugal force. This principle has been instrumental in the development of many Urschel machines," says Dan Urschel, who has spent 50 years at the family-owned company. Long-time employees also recall the innovative and inventive members of the second generation. "Coming up with new cutting solutions, and improving on current cutting methods is a vital part of our business," states Mike Jacko, vice president of Engineering, and who has been with Urschel for 24 years. "When I started with the company, I remember Joe (Urschel) and Gerald (Urschel) being granted many patents for different cutting processes. In their lifetimes, they were granted over 70 patents," adds Mr Jacko. "The engineering department continues to employ valuable, talented engineers, and continues to be awarded patents in food cutting machinery." Precision in manufacturing means that every cutting machine is carefully designed from the engineering drawingsNike

"As adults, Joe and Gerald began working full time at Urschel. Amongst their many accomplishments, Joe is credited with developing and patenting the first slicer that used centrifugal force. This principle has been instrumental in the development of many Urschel machines," says Dan Urschel, who has spent 50 years at the family-owned company. Long-time employees also recall the innovative and inventive members of the second generation. "Coming up with new cutting solutions, and improving on current cutting methods is a vital part of our business," states Mike Jacko, vice president of Engineering, and who has been with Urschel for 24 years. "When I started with the company, I remember Joe (Urschel) and Gerald (Urschel) being granted many patents for different cutting processes. In their lifetimes, they were granted over 70 patents," adds Mr Jacko. "The engineering department continues to employ valuable, talented engineers, and continues to be awarded patents in food cutting machinery." Precision in manufacturing means that every cutting machine is carefully designed from the engineering drawingsNike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login