Machining with machine tools generates heat in various parts of the equipment due to the high power involved, the friction related to the high mechanical forces applied together with the high rotation speed of the tools. Heat increases the temperature of all involved parts including electric motors, drives, spindles, working tools and workpieces, causing the metal to expand, a condition that would jeopardise the machining accuracy if not properly managed by a dedicated thermal control system. For this purpose, oil and coolant are circulated inside the machine to cool the components/tools and the mechanical part being machined. The cooling system just described is called chiller. Its performance is preventing the state of the machine or workpiece under manufacturing from heat distortion by recovering the heat that the oil or the coolant transports out of the machine and keeping the liquid temperature ideally perfectly constant.

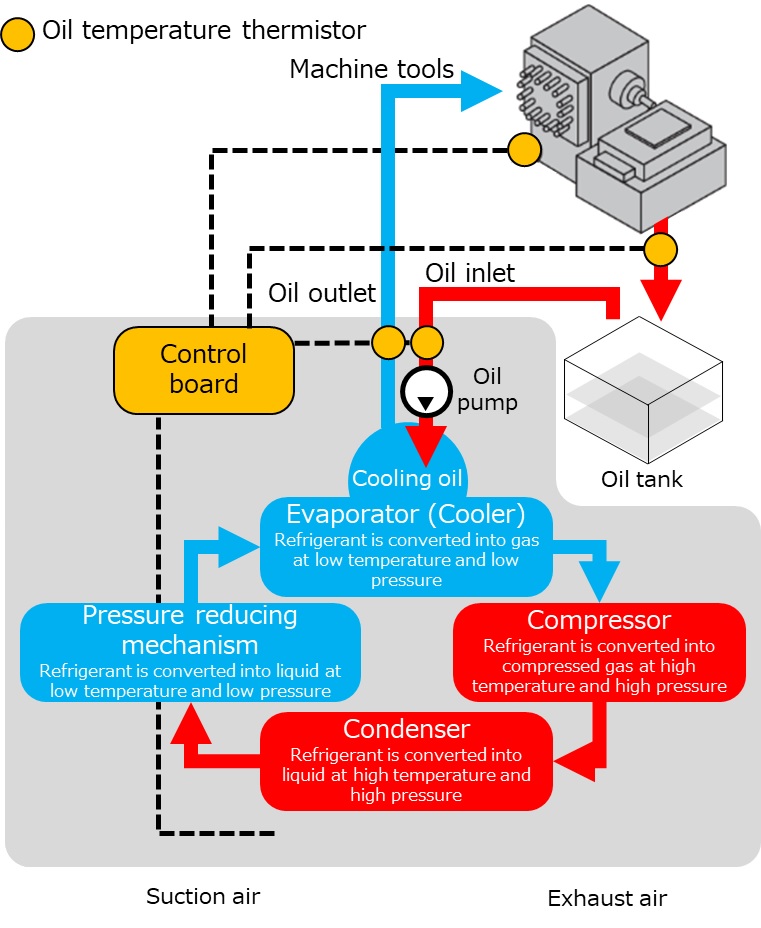

Figure 1: Schematic diagram of the chiller working principle.

Chiller operating principle

Unlike water coolers and fan coolers, chillers perform arbitrary temperature control not only by exchanging heat but also by controlling the refrigerant temperature. With reference to Figure 1, the operating principle of chillers is based on the following four steps:

① The refrigerant gas, that is contained in an isolated closed circuit, is compressed by a compressor to produce high temperature, high-pressure compressed gas.

② The compressed gas is cooled and condensed by a condenser to produce a high-temperature, high-pressure liquid.

③ In the decompression mechanism, this high-temperature, high-pressure liquid is squeezed and decompressed through an electronic expansion valve to produce a low-temperature, low-pressure liquid that can be easily evaporated by a heat-exchanger (evaporator). The amount of refrigerant circulating is controlled by changing the valve opening in response to the capability command.

④ The energy absorbed by the refrigerant in the evaporator is provided by the oil, that therefore cools down. During this process the heat transferred to the refrigerant from the oil (latent heat of vaporisation) produces the evaporation of the liquid, turning it into a low-temperature, low-pressure gas that is conveyed back to the compressor, where the cycle starts again.

The above cycle is managed by dedicated electronics that controls very precisely each step of the thermal conditioning.

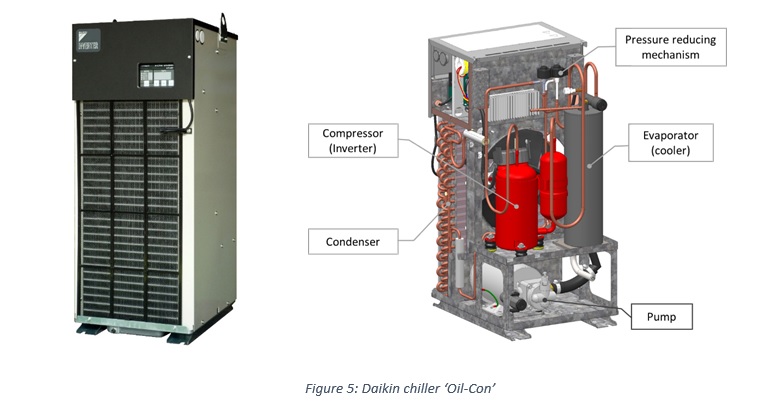

Daikin’s Hybrid Technology "Oil-Con"

Daikin Industries is a well-known global manufacturer of air conditioners and hydraulic components. In June 2022, Daikin acquired Duplomatic Motion Solutions, a global player active in the design and manufacturing of components and systems for motion applications, with a strong heritage in fluid power. Within its hydraulic division, that includes Duplomatic Group, Daikin develops and manufactures high-performance energy-efficient chillers for machine tools under the name "Oil-Con.” The name has been inspired by its long tradition in air conditioning, where Daikin differentiates itself by taking advantage of its strong competences in refrigeration and inverter technologies. In fact, among the many players active in the development of air conditioning equipment, Daikin is the only actor developing internally all critical components used for the refrigeration cycle. Daikin’s chemical division is a leading-edge player developing refrigerants of different kinds with a strong focus on green technologies. Daikin introduced the inverter technology for the energy-efficient control of electric motors since 1986 and since then – thanks to the mass-production of inverters - lot of progresses have been made in developing cost-effective high-efficient units with sophisticated control algorithms aimed to control special designed IPM motors that are part of every Daikin equipment. In Oil-Con chillers the combination of these technologies result in high accurate temperature controls and unique energy savings.

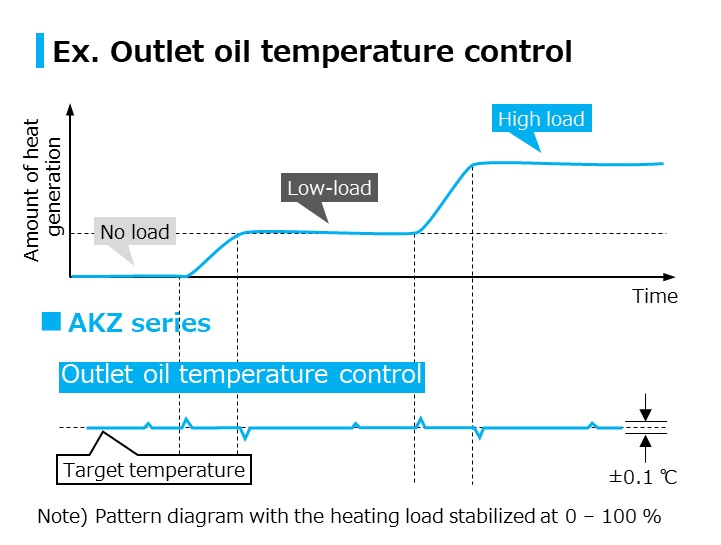

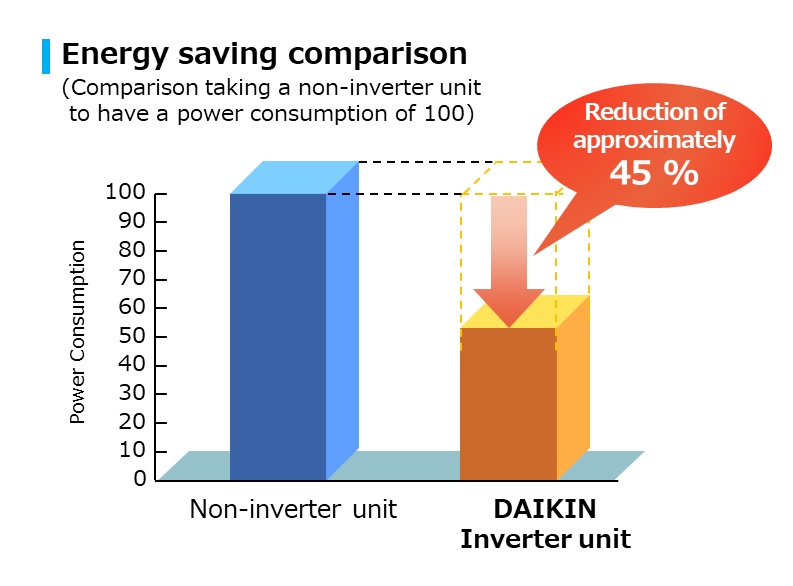

In fact, the inverter-controlled compressor allows to achieve the required cooling capacity adapting the compression power to the actual heat load, thus avoiding unnecessary power consumption. The highly efficient IPM motor is driven by its dedicated drive adjusting the compressor speed according to the required cooling capacity, resulting in a highly accurate thermal control with typical accuracies of ± 0.1°C. The thermal control performance is almost independent from the thermal load (Figure 2). Compared to non-inverter models from other competitors, power consumption can be reduced by typically 45% (Figure 3).

Figure 2: Accurate temperature control

Figure 3: Energy saving comparison between Daikin Inverter Technology compared to standard compressor control

Daikin “Oil-Con” Chiller Family

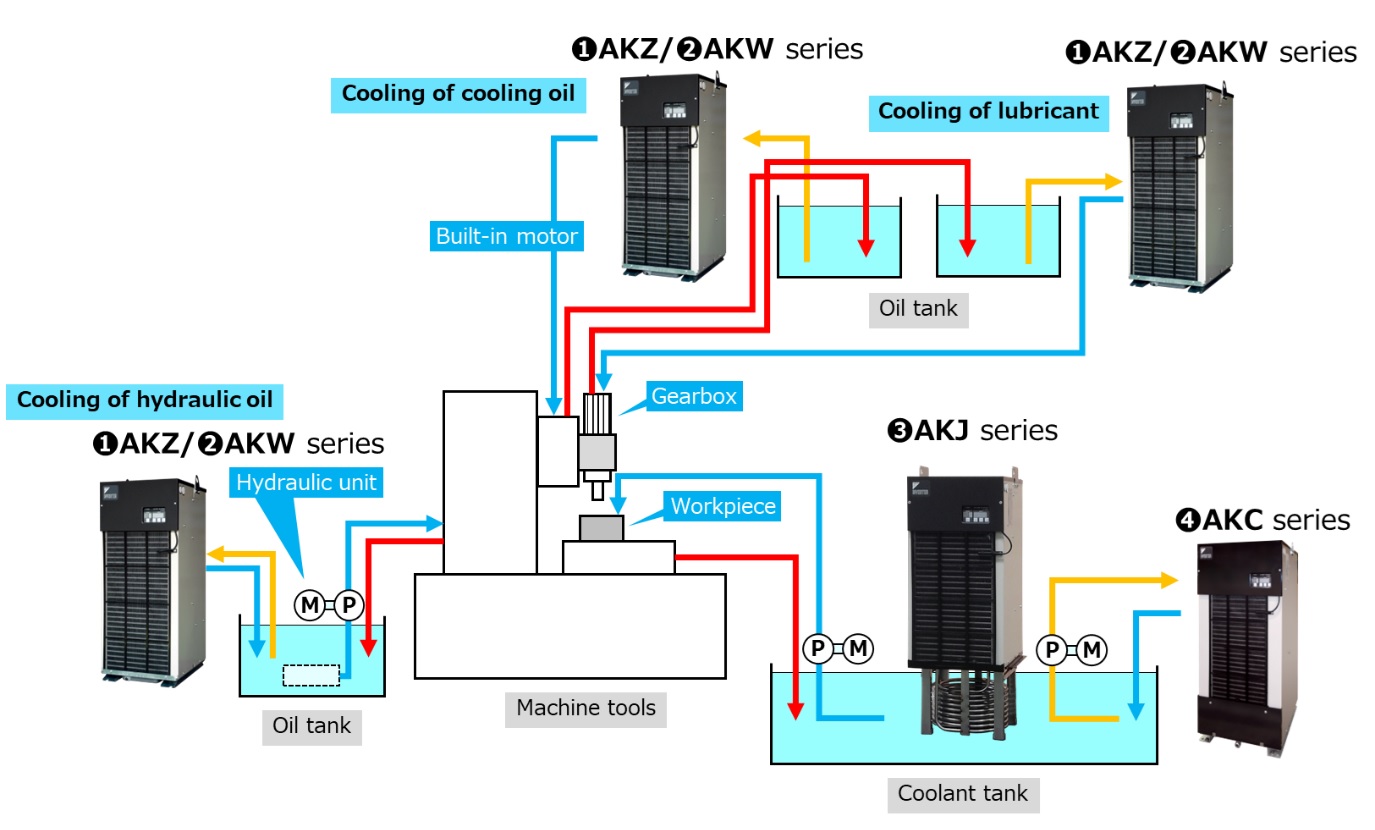

Based on the technologies described in the previous paragraph, Daikin has developed different chiller configurations for cooling coolants, lubricants, hydraulic and cutting oils in machine tools, as shown in the following picture.

Four types of chillers are available depending on the type of liquid to be cooled and the installation method, considering either oil or water as fluids and two different installation configurations (recirculating or immersion type). The temperature control method can be changed as needed by the application. Three control methods are available. They include: (1) control to match any fixed temperature, (2) control to synchronise to room temperature, and (3) control to synchronise to machine tool temperature.

Figure 4: Application of chillers

Using Big Data to Innovate the Temperature Control Technology

As machine tools become more precise, high precision is required for controlling liquid temperature. A long-term development trend for chillers is the improvement of liquid temperature control accuracy. Current models, such as the recirculating AKZ9 and AKZ10 series, and the tank-immersion AKJ9 series, achieve a standard temperature accuracy of ± 0.1°C, while special specifications support temperature accuracies down to ± 0.01°C, being the accuracy almost independent from the heat load.

Recently, the installation of Internet of Things (IoT) related functions in machine tools has become the standard. User needs for IoT related functions in chillers are increasing year by year, and new developments are underway. Monitoring of chillers has already been commercialised, but the first stage has been limited to just connecting the equipment. Currently, data are collected to establish the correlation between chiller fluid temperature and machine tool processing accuracy. In the future, the use of artificial intelligence and machine learning applied to these data will allow the quantitative determination of the relationship between fluid temperature and machine processing accuracy.

This will enable the next step of control accuracy, moving from a feedback system that follows the change in the liquid temperature and cools it, to a predictive control where changes in the liquid temperature are suppressed by predicting the needed temperature control from the machine processing content.

Daikin's Environmental Vision

With the increasing precision of machine tools, the number of chillers installed is increasing. Machine tool manufacturers are aiming for more environmentally friendly designs, and the demand for inverter chillers with high energy-saving performance is increasing even more.

Daikin’s vision is based on sustainability and to the contribution it can give to society to achieve sustainability through its products. Daikin aims to achieve net zero greenhouse gas emissions in 2050, halving the emissions already in 2030. The company strongly promotes the adoption of inverter technology within all its products and strongly invests in the development of the core technologies required to improve the energy efficiency of equipment. They include basic research in high-efficiency electric motors, inverters, real-time motor control technologies, chemicals, environmental-friendly high-efficient refrigerants, as well as the recycling of the equipment and the recovery of the refrigerants in the market at the end of the product life-cycle.

By: Paolo Leutenegger, General Manager, Duplomatic MS; Jumpei Yamamoto, Senior engineer, Engineering Dept., Oil Hydraulics Div., Daikin Industriesx

Property of Duplomatic MS

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login