THE concept of the hybrid process is based on the combination of two established welding processes, the processes in this case being laser welding with GMAW. For reference it shall be mentioned that the HybridLaser welding process can also be a combination of laser and GTAW or laser and PAW. The laser itself can be a CO2 laser, Nd:Yag, diode, Yb:YAG disc or Yb fibre. In the welding head, that is carrying both the optics and the welding torch (GMAW, GTAW, PAW), the two processes meet each other and are joined into the same weld pool meaning that we now have a new process that is built up of two sub-processes. There are properties from each process that will be combined in to one. The disadvantages normally found in each single process now being compensated by the advantages from the combined new process. The end result being the excellent new HybridLaser welding process, which has the ability to weld over gaps, requiring minimal joint preparation while providing very high levels of productivity.

THE concept of the hybrid process is based on the combination of two established welding processes, the processes in this case being laser welding with GMAW. For reference it shall be mentioned that the HybridLaser welding process can also be a combination of laser and GTAW or laser and PAW. The laser itself can be a CO2 laser, Nd:Yag, diode, Yb:YAG disc or Yb fibre. In the welding head, that is carrying both the optics and the welding torch (GMAW, GTAW, PAW), the two processes meet each other and are joined into the same weld pool meaning that we now have a new process that is built up of two sub-processes. There are properties from each process that will be combined in to one. The disadvantages normally found in each single process now being compensated by the advantages from the combined new process. The end result being the excellent new HybridLaser welding process, which has the ability to weld over gaps, requiring minimal joint preparation while providing very high levels of productivity.

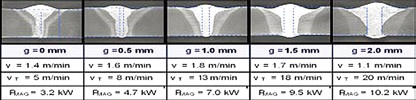

As seen in figure 1, it is possible to achieve a good gap bridging capability with the process and at the same time maintain a high welding speed. This is one of the advantages with the process that is the result from the joining of laser and GMAW welding. Process stability, speed and penetration come from the laser and the gap bridging properties comes from the GMAW.

Other significant properties associated with the HLAW process is the reduction in heat input to the base material. This in combination with the greatly reduced weld joint volumes is responsible for minimizing the distortion of the welded objects. This contributes to a major reduction in the need for post weld work, i.e. straightening of plate and objects and this reduces the overall costs significantly.

Welding head

Depending on the choice of laser source, the integration of the laser and the arc welding process in the welding head will be different; the design of heads may vary a lot. There is also different optics available on the market and there are different control systems for the welding process, this will also influence the design of the welding head. The most important feature is that the size of the head is not hindering access to the welded object and the attachment of the object in the welding fixture. If the welded object does not give any restrictions in limiting the height of the object a straight optics can be chosen.

Longitudinal joining of pipe

There are different production philosophies for how to perform the longitudinal seam welding of a pipe when it comes to joint preparation and the choice of processes. In this case we have looked at pipes for the offshore industry and in particular, so called raiser pipes. Raiser pipes are used for the transport of oil/gas from the well to any production site. The pipes are made from cladded material, stainless or Ni-base on the inside of the pipe, the composition of the cladded material is dependant on the corrosiveness of the media that is transported in the pipe. The pipe material is selected to meet the requirements and specification laid down by the client. The pipe tested in this investigation is an API 5L X-70 pipe.

C = 0,25 – 0,37; Mn = 1,31 – 1,53; Nb = 0,082 – 0,095 and Ti = 0,008 – 0,015. This particular steel is a TMCP type. The cladding layer in this case is a 309 material and the thickness of the layer is 3 mm. In this investigation we only look at the welding of the longitudinal joint, not the welding of the cladding layer after the joining of the long seam, as this will be exactly the same procedure irrespective of the way the longitudinal joint is performed.

The wall thickness of the pipe (API 5L X-70) is 16 mm and the thickness of the cladding layer (309L) is 3 mm. The length of a pipe is 12 meter.

Present joining procedure

The current method of producing the pipes is according the following schedule:

- Joint preparation (milling)

- Forming of the pipe

- Tack welding of the joint (GTAW)

- Root pass welding (PAW)

- Hot pass welding (GMAW)

- Fill & cap (SAW)

- Quality control

From the point where the tack welding starts, up to the final weld station, the cycle time is 135 minutes, this includes all handling time and changing of the welding equipment between the different beads.

The joint preparation is done in an automatic milling station with a following quality station where the tolerances of the preparation is checked. After welding there is also a quality check with MP and ultrasonic tests, before the pipe is approved and stamped with OK sign.

There are different ways of designing the preparation for this joint and what is unavoidable is that irrespective of which preparation method and processes are used, a back bead must be done from the inside, with the same consumable composition as that of the cladding layer, in order to assure a sound inside.

The cycle time for the welding operation is as follows:

- Tack welding (GTAW) 6 min

- Handling 5 min

- Root pass welding (PAW) 48 min

- Handling 5 min

- Hot pass (GMAW) 26 min

- Handling 5 min

- Fill & cap welding (SAW) 40 min

Hybridlaser joining procedure

During the trials for the HLAW process a number of different joint preparations were evaluated before the final was chosen. The new way of welding is done according to the following schedule:

- Joint preparation (milling)

- Forming of the pipe

- Tack welding of the joint (GTAW)

- Final welding (HLAW)

- Quality control.

Instead of 4 welding operations, in the conventional welding method, we now have only tack welding and the final welding operation. This reduces the welding cycle considerably and also takes away a number of welding equipment changes that are necessary with the old method. The total heat input to the joint is now also much lower which reduces the amount of time spent on straightening of the pipe after welding.

Figure 1. Gap bridging capabilities

The cost for 1 pipe. The cost for producing 1.000 pipes will add up to 279.700:- SEK

This is a time saving with a factor of 6,6.

This is a cost saving with a factor of 2,7.

The investment in a new and expensive process like HLAW is often dismissed due to the cost. But when using the process for an application where it is possible to utilize all benefits from the process, so much time saved, the production cost of the product being welded will be greatly reduced and this will make the investment very sound. The payback time for this investment will be approximately 1,5 years and the depreciation time calculated for the investment is 5 years, resulting in a very good margin after 1,5 years (the payback time).

By: Lars-Erik Stridh, IWE, Global Welding Application Manager, ESAB AB

Air Max 95 20th Anniversary

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login