COMPLYING with stringent food safety regulations and increasing productivity are priorities that conveyor system manufacturers deal with in satisfying the requirements of food and beverage manufacturers.

For major conveyor system suppliers Dorner Manufacturing Corporation and Interroll fulfilling the demands posed by the challenges and trends taking place in the food manufacturing and processing industries, at the same time exceeding customers’ expectations, are imperative.

“The challenges that face the conveyor market when it comes to serving the food industries is being able to offer equipment that meets government mandates and regulations, while also meeting the needs of its customers. Time is money with most food processors; they can’t afford to have a conveyor system go down for maintenance. But at the same time, they need a conveyor that’s built to operate in harsh sanitary environments,” explains Stacy Johnson, senior marketing manager, Dorner Mfg. Corp. “The need for equipment to be sanitary in the food manufacturing and processing industries has never been more prevalent in the United States than what it is right now, and that’s mainly due to the reforms called out in the Food and Drug Administration Food Safety Modernization Act (FSMA).”

Enacted five years ago, the FSMA seeks to guarantee the safety of the US food supply by shifting the focus of federal regulators from responding to contamination to preventing it.

Stacy Johnson, senior marketing manager, Dorner Mfg. Corp

Interroll has observed that adoption of their smart and hygienic technology for the food industry in Asia remains low compared to Western countries. “However, local companies in the region, especially the leading players, are starting to recognize the benefits of such advanced technology, along with the increasing public awareness of food safety issues in China among other Asia-Pacific regions. That could translate to big business opportunities for Interroll,” discloses a company spokesperson. “Prompting the food industry to adopt advanced technology is an incremental process, now we are trying our best to deliver our customers with product technology featuring efficient, cost-saving and energy conservation, to let them see the visible benefits they get from us.”

Threat of foodborne illnesses

Aside from the FSMA, the European Union (EU) regulations have also affected the way food sector businesses run their manufacturing plants. More proactive initiatives are transforming their operations by focusing on risk management related issues, the growing threat of foodborne illnesses being one of them.

Foodborne illnesses continue to pose a risk to the global public health. Low- and middle-income countries are most vulnerable due to poor hygiene, unsafe water, inadequate conditions in food production and storage, low literacy levels and lacking food safety legislations or executions of such laws.

The Centers for Disease Control and Prevention estimates about 48 million cases, 3,000 deaths and 128,000 hospitalizations from foodborne pathogens annually in the US alone.

The World Health Organization (WHO) reports that Africa and Southeast Asia have the highest incidence and highest death rates, including among children below five years old. Although Southeast Asia has the second-highest burden of foodborne disease per population, second only to Africa, it has the highest in terms of absolute numbers of people affected by foodborne diseases with more than 150 million cases and 175,000 deaths a year.

In an industry handout by Interroll it sees food safety as becoming increasingly important for the food processing sector for a number of reasons. First on the list, foodborne illnesses that plague the global supply chain. Second is the increasing enforcement of existing regulations by EU and the US Food and Drug Administration, giving food safety and food manufacturing enforcement greater visibility. Third is a trend to focus on health claims made by food manufacturers on functional foods. Fourth is the threat of product recall because there is a growing vigilance and monitoring of the quality and safety of foods put on the market shelves.

Taking products off the shelves happens when there is a safety issue or defect in the product. Once discovered, companies voluntarily recall affected products, although, there are instances when a government agency orders it. Aside from the prospect of losing millions, it can also mean the end of the business.

Meeting rigorous requirements

According to Ms Johnson more of onus is now being placed on manufacturers to build equipment that helps their customers conform to these new standards called out in the FSMA.

“We here at Dorner have been ahead of the curve for a number of years in designing sanitary conveyor systems that prevent contamination. Our AquaPruf and AquaGard sanitary conveyor platforms meet Baking Industry Sanitary Standards Committee (BISSC), National Sanitation Foundation (NSF) and FDA regulations. Additionally, our AquaPruf 7400 and 7600 Ultimate platforms are the only US Department of Agriculture-certified conveyors operating in the industry; they’re the only modular conveyors on the agency’s list of accepted equipment for the meat and poultry industry.”

Ms Johnson explains, “A common concern is the time needed to clean and sanitize their conveyors. When it comes to washing down equipment, speed has always been, and will continue to be an important factor. While some applications call for a daily cleaning, others require multiple cleanings several times a day. For those applications, having equipment down for cleaning can certainly affect production. The key is to fully sanitize a piece of equipment in the least amount of time. With that in mind we’ve designed our sanitary conveyor platforms to be completely disassembled, by one person, and ready for cleaning in less than two minutes. The entire process of disassembly, cleaning and reassembly literally takes less than 10 minutes – this is a process that can be accomplished by one person with no tools required. For many applications, speed counts, and that’s one of the advantages we provide to our customers.”

The Dorner AquaPruf Vertical Belt Technology conveyor with FDA approved belting and plastic components

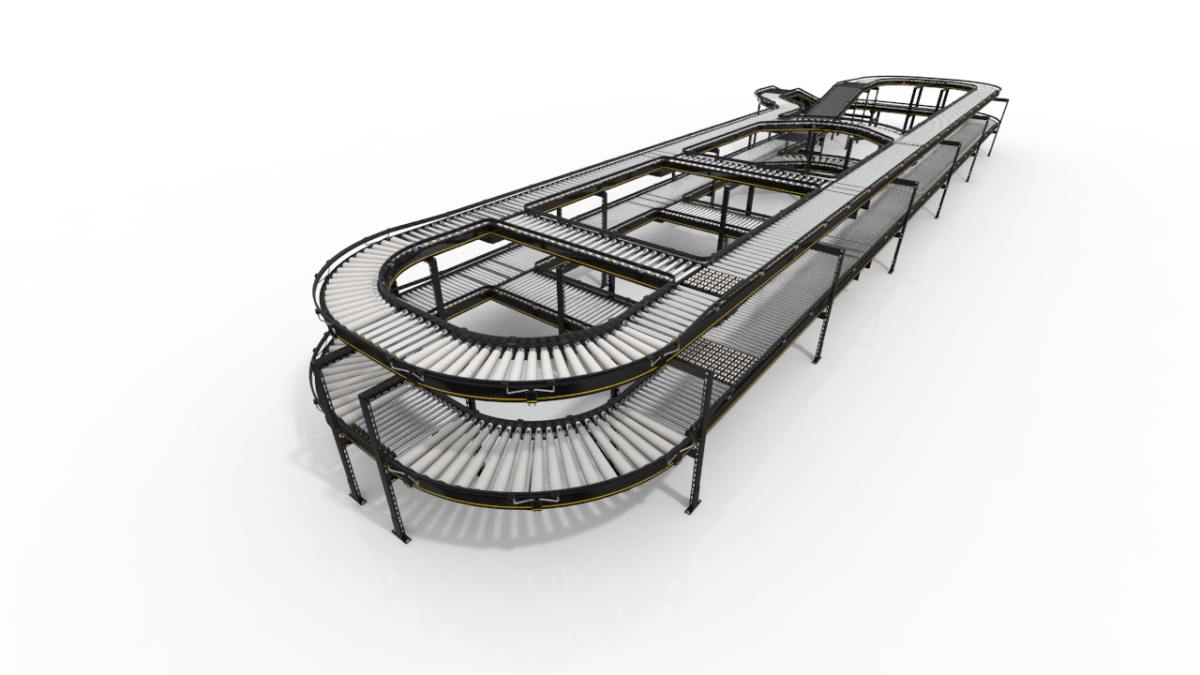

For Interroll’s part, it officially launched on October 2015 a modular conveyor platform geared to satisfy the region’s industry needs. “The new product is an innovation in conveyor systems market and can meet various demand of different customers. The new platform helps customers meet the current and future challenges of material logistics system by improving productivity, increasing flexibility and lowering costs of operation and maintenance. The customer feedback that we have received thus far suggests strong interest in this brand new product in the region,” according to Interroll.

Interroll’s Modular Conveyor Platform allows customers to combine all of Interroll’s most important products to form a complete system

Outlook for Asia Pacific

A recent report by research firm Future Market Insights revealed that the global conveyor systems market will continue to see a steady CAGR of 3 percent to 4 percent for the period 2014-2020 while market research and consulting company MarketsandMarkets estimated that the global conveyor systems industry will be worth nearly US$ 6.3 billion by 2018 and identifying Asia Pacific as a potential and growing market for conveyor systems.

MarketsandMarkets further noted that several industries in the region, including those in food and beverage, are expanding at a healthy growth rate causing businesses to make sizable capital investments either to expand existing facilities or build new plants.

“As far as our outlook on the Asia Pacific market – we feel very strongly that this region holds tremendous growth potential, as food processors and packagers there are facing the same issues as their counterparts here in North America. They need sanitary conveyors that can operate around the clock, and be cleaned in just a few minutes,” says Ms Johnson.

On December 2015, Dorner acquired Malaysia-based Flexmove which manufactures flexible chain conveyors for the F&B industry. “The integration of FlexMove, a company whose views on product quality and delivery are in line with Dorner, will be a positive development for food manufacturers and packagers in the Asia Pacific region,” she stated.

Interroll says the region, especially in China which is the second-fastest growing F&B market in this region, the food & beverage industry, along with other end-use industries for conveyor systems, are growing at a healthy rate, thereby boosting the growth of conveyor systems market. “We have been investing continuously in Asia-Pacific since 1988 to serve a wide range of industries including the food and beverage sector. We have been expanding our presence, in particular in the past three years, along with the growing demand of material handing solutions and the increasing automation in industrial sectors. In 2014, Interroll acquired Pert Engineering in Shenzhen of China, and put our new production facility in Suzhou, China, into operation in August 2015 since the local regional Center of Excellence located there had reached its maximum production capacity. Production has expanded now to include the modular conveyor platform. The Center of Excellence in Suzhou serves all of our customers in Asia.”

Interroll’s synchronous drum motors combine the advantages of a drum motor with the high efficiency of a synchronous servo motor. The result is a compact and dynamic drive with an outstanding efficiency of about 85 percent

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login