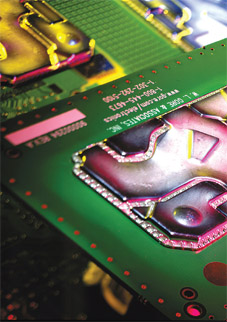

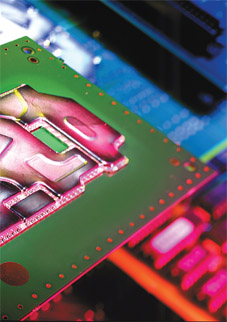

With present preference for lightweight, environment-friendly and highly durable electronics, innovative materials are now offering value-added features that create a big difference in the electronics products available today. Lexan polycarbonate (PC) film technology-Lexan EFR film-delivers non-brominated, non-chlorinated flame retardance (FR) at thinner gauges than flame-retardant polypropylene (FRPP). This material from Sabic Innovative Plastics enables electrical/electronics (E/E) OEMs to create flatter, lighterweight notebook computers and other electronic devices while significantly reducing material costs. The Lexan EFR film presents an environmental solution that increases the ability of global E/E manufacturers to go beyond current environmental directives by voluntarily eliminating halogenated additives in their products. "As E/E OEMs step up to meet anticipated and ever-tightening environmental requirements, we are taking the initiative in engineering precisely targeted materials technologies to help proactively address these changes," said Mr. Lennard Markestein, global marketing director for Specialty Film & Sheet, SABIC Innovative Plastics.

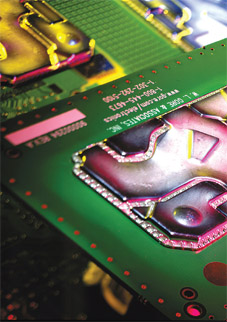

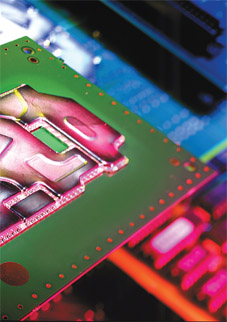

Lexan EFR polycarbonate-based film offers flame retardance without the use of brominated or chlorinated additives-materials that can be harmful to the environment-thus meeting the requirements of the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE 2006) directives. Further, these new materials have a full listing in the Underwriters Laboratory (UL) yellow card system. According to UL 94, Lexan EFR film-available in clear and opaque versions-delivers V-0 performance above 380 microns; VTM-0 flame resistance performance down to 125 microns for translucent and 100 microns for opaque materials; and complies with TCO-99 eco label requirements. Compared to FRPP, Lexan EFR film reduces shrinkage by a factor of three, provides significantly higher puncture resistance and tensile strength. These properties make it feasible to use very thin gauges of Lexan EFR film to replace thicker FRPP film without sacrificing performance. Not only do thinner gauges help designers create slimmer and lighterweight consumer electronics, but down-gauging also lowers total costs by reducing the amount of material required. The new film also provides low moisture absorption, high thermal performance (glass transition temperature of 170°C) and excellent dielectric strength. Target applications for this material include insulation for printed circuits, printed circuit board, disk drive, keyboard, inverters and adaptors, die-cut spacers, labels and overlays.

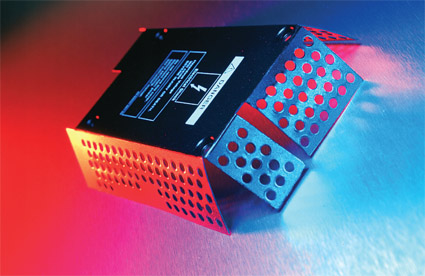

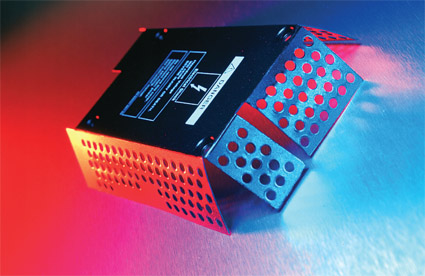

Electromagnetic interference/radio frequency interference (EMI/RFI) shielding is another important benefit provided by Lexan EFR film. As regulatory agencies continue to tighten restrictions on EMI/RFI emissions, electronic device manufacturers are looking for new shielding solutions to replace metal boxes, conductive paints, plating, metal chassis and conductive polymers that add weight and cost. Lexan EFR film provides a low-cost, lightweight solution for both primary and secondary (problem area) shielding, while maintaining UL recognition. Lexan EFR film can be easily fabricated using thermoforming, embossing, clean-edge die cutting, scoring and bending. The product is available globally in matte/ polish and velvet/matte finishes and various gauges between 100 and 762 microns. Another important E/E material from SABIC Innovative Plastics is Ultem polyetherimide (PEI) film, offering excellent dielectric, high-temperature and chemical resistant properties. Ultem films carry the Blue Angel, EcoMark (Japan), Nordic Swan and TCO-99 labels, successfully passed stringent Verband der Elektrotechnik Elektronik

Jordan XII Slide With present preference for lightweight, environment-friendly and highly durable electronics, innovative materials are now offering value-added features that create a big difference in the electronics products available today. Lexan polycarbonate (PC) film technology-Lexan EFR film-delivers non-brominated, non-chlorinated flame retardance (FR) at thinner gauges than flame-retardant polypropylene (FRPP). This material from Sabic Innovative Plastics enables electrical/electronics (E/E) OEMs to create flatter, lighterweight notebook computers and other electronic devices while significantly reducing material costs. The Lexan EFR film presents an environmental solution that increases the ability of global E/E manufacturers to go beyond current environmental directives by voluntarily eliminating halogenated additives in their products. "As E/E OEMs step up to meet anticipated and ever-tightening environmental requirements, we are taking the initiative in engineering precisely targeted materials technologies to help proactively address these changes," said Mr. Lennard Markestein, global marketing director for Specialty Film & Sheet, SABIC Innovative Plastics.

With present preference for lightweight, environment-friendly and highly durable electronics, innovative materials are now offering value-added features that create a big difference in the electronics products available today. Lexan polycarbonate (PC) film technology-Lexan EFR film-delivers non-brominated, non-chlorinated flame retardance (FR) at thinner gauges than flame-retardant polypropylene (FRPP). This material from Sabic Innovative Plastics enables electrical/electronics (E/E) OEMs to create flatter, lighterweight notebook computers and other electronic devices while significantly reducing material costs. The Lexan EFR film presents an environmental solution that increases the ability of global E/E manufacturers to go beyond current environmental directives by voluntarily eliminating halogenated additives in their products. "As E/E OEMs step up to meet anticipated and ever-tightening environmental requirements, we are taking the initiative in engineering precisely targeted materials technologies to help proactively address these changes," said Mr. Lennard Markestein, global marketing director for Specialty Film & Sheet, SABIC Innovative Plastics.  Lexan EFR polycarbonate-based film offers flame retardance without the use of brominated or chlorinated additives-materials that can be harmful to the environment-thus meeting the requirements of the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE 2006) directives. Further, these new materials have a full listing in the Underwriters Laboratory (UL) yellow card system. According to UL 94, Lexan EFR film-available in clear and opaque versions-delivers V-0 performance above 380 microns; VTM-0 flame resistance performance down to 125 microns for translucent and 100 microns for opaque materials; and complies with TCO-99 eco label requirements. Compared to FRPP, Lexan EFR film reduces shrinkage by a factor of three, provides significantly higher puncture resistance and tensile strength. These properties make it feasible to use very thin gauges of Lexan EFR film to replace thicker FRPP film without sacrificing performance. Not only do thinner gauges help designers create slimmer and lighterweight consumer electronics, but down-gauging also lowers total costs by reducing the amount of material required. The new film also provides low moisture absorption, high thermal performance (glass transition temperature of 170°C) and excellent dielectric strength. Target applications for this material include insulation for printed circuits, printed circuit board, disk drive, keyboard, inverters and adaptors, die-cut spacers, labels and overlays.

Lexan EFR polycarbonate-based film offers flame retardance without the use of brominated or chlorinated additives-materials that can be harmful to the environment-thus meeting the requirements of the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE 2006) directives. Further, these new materials have a full listing in the Underwriters Laboratory (UL) yellow card system. According to UL 94, Lexan EFR film-available in clear and opaque versions-delivers V-0 performance above 380 microns; VTM-0 flame resistance performance down to 125 microns for translucent and 100 microns for opaque materials; and complies with TCO-99 eco label requirements. Compared to FRPP, Lexan EFR film reduces shrinkage by a factor of three, provides significantly higher puncture resistance and tensile strength. These properties make it feasible to use very thin gauges of Lexan EFR film to replace thicker FRPP film without sacrificing performance. Not only do thinner gauges help designers create slimmer and lighterweight consumer electronics, but down-gauging also lowers total costs by reducing the amount of material required. The new film also provides low moisture absorption, high thermal performance (glass transition temperature of 170°C) and excellent dielectric strength. Target applications for this material include insulation for printed circuits, printed circuit board, disk drive, keyboard, inverters and adaptors, die-cut spacers, labels and overlays.  Electromagnetic interference/radio frequency interference (EMI/RFI) shielding is another important benefit provided by Lexan EFR film. As regulatory agencies continue to tighten restrictions on EMI/RFI emissions, electronic device manufacturers are looking for new shielding solutions to replace metal boxes, conductive paints, plating, metal chassis and conductive polymers that add weight and cost. Lexan EFR film provides a low-cost, lightweight solution for both primary and secondary (problem area) shielding, while maintaining UL recognition. Lexan EFR film can be easily fabricated using thermoforming, embossing, clean-edge die cutting, scoring and bending. The product is available globally in matte/ polish and velvet/matte finishes and various gauges between 100 and 762 microns. Another important E/E material from SABIC Innovative Plastics is Ultem polyetherimide (PEI) film, offering excellent dielectric, high-temperature and chemical resistant properties. Ultem films carry the Blue Angel, EcoMark (Japan), Nordic Swan and TCO-99 labels, successfully passed stringent Verband der Elektrotechnik ElektronikJordan XII Slide

Electromagnetic interference/radio frequency interference (EMI/RFI) shielding is another important benefit provided by Lexan EFR film. As regulatory agencies continue to tighten restrictions on EMI/RFI emissions, electronic device manufacturers are looking for new shielding solutions to replace metal boxes, conductive paints, plating, metal chassis and conductive polymers that add weight and cost. Lexan EFR film provides a low-cost, lightweight solution for both primary and secondary (problem area) shielding, while maintaining UL recognition. Lexan EFR film can be easily fabricated using thermoforming, embossing, clean-edge die cutting, scoring and bending. The product is available globally in matte/ polish and velvet/matte finishes and various gauges between 100 and 762 microns. Another important E/E material from SABIC Innovative Plastics is Ultem polyetherimide (PEI) film, offering excellent dielectric, high-temperature and chemical resistant properties. Ultem films carry the Blue Angel, EcoMark (Japan), Nordic Swan and TCO-99 labels, successfully passed stringent Verband der Elektrotechnik ElektronikJordan XII Slide

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login