interpack 2023 has opened its doors to unveil the world’s cutting-edge processing and packaging machinery and equipment, for startups and big companies alike.

The much-awaited event is on-going from 4 to 10 May 2023 in the fair ground of Düsseldorf. The 18 exhibition halls are fully packed with the latest designs, materials, technologies, and services for food, beverage, pharmaceutical, home and personal care production. There will be scheduled spotlight talks, product launches, and lectures throughout the seven days.

Some 2,700 exhibitors at this event represent 60 countries and are mostly from Italy, China, Turkey, India, the Netherlands, the USA, France, Spain, Switzerland the United Kingdom, and of course Germany.

Trade visitors can expect to find what they are looking for when it comes to efficiency, sustainability, food safety, waste reduction, with the aim to reduce cost.

Baumer hhs GmbH

Hall 18 stand H10

As a pioneer of electric cold glue and hot melt application heads for industrial gluing, Baumer hhs has been supplying its customers with innovative solutions that help optimise production processes. The company will be exhibiting its latest products for improving the sustainability of packaging applications at its stand in Hall 18 (H10) under the theme “Less is more – Saving resources with sustainable packaging solutions”.

Intelligent solutions for securing pallets in end-of-line packaging using pressure-sensitive adhesive as an alternative to shrink-wrap

Highlights:

- Demo of the XmeltBio in action as it applies bio-based adhesives

- Intelligent solutions for securing pallets in end-of-line packaging using pressure-sensitive adhesive instead of shrink-wrap

- High-performance systems for applying pressure-sensitive adhesives in the production of e-commerce boxes

- Electric Delta application head, developed for box closing applications

Domino Printing Sciences PLC

Hall 8b C41

The U510 UV Laser addresses the challenges in coding recyclable plastics

Domino Printing Sciences PLC has launched the U510 UV Laser to help manufacturers code onto recyclable food packaging film.

“Laser coders are a very popular solution for many food and beverage manufacturers looking to add reliably crisp, machine-scannable QR codes, batch and product information, and logos at very high speeds,” says Felix Rief, Head of Laser and Extraction, Domino. “However, certain new sustainable food packaging materials, including mono-material recyclable plastics, can prove challenging to code using traditional fibre or CO2 laser coders. We developed the U510 UV laser to offer manufacturers a reliable laser coding solution for these new sustainable packaging solutions.”

Fortress Technology Europe

Hall 11 booth E30

Fortress Technology Europe’s X-ray range will be unveiled at interpack, in response to food supermarkets and wholesalers insisting that food processors and vendors install x-ray and metal detection on production and packaging lines.

The company will present its space-saving Combination X-Ray and Checkweigher, Multi-lane designs, as well as standalone X-Ray machines, which are all available with either a dipping conveyor, pusher or air blast reject system. For processors of meat and other pumped foods, Fortress also supplies an easy-clean X-Ray Pipeline system.

Highlights:

The Raptor X-Ray is available in two belt widths – 300mm and 400mm. It inspects and rejects packaged meat, cheese, chilled and confectionery products that present with metal, glass, wood, rubber, high density plastic, stone and calcified bones.

For bulkier applications, the XL 500mm belt stop and alarm conveyor X-Ray system can monitor fill levels, identify ingredient clumps, broken or missing product and spot damaged packaging.

The entire Fortress X-Ray series automatically integrates international retailer codes of practice into the testing software, programming them into each machine menu before installation on food production lines.

Rather than using compressed air to cool and regulate the temperature of the x-ray filaments, the Fortress X-Ray range instead features electric servo drives. These electric drives enable both the conveyor and pipeline x-ray machines to reject contaminated product faster and more accurately than other comparable food x-rays on the market

With filaments in an x-ray tube running hotter when more current is demanded, the Fortress X-Ray range typically runs at 60kV, half the usual voltage. An entire system only requires a maximum 10 amps to operate, compared to an air-conditioned x-ray which typically needs 16 amps. This can add up to an annual saving of EUR 4,600 for each x-ray.

Sloping angles, magnetic x-ray curtains, an easy to remove conveyor, IP69k-rated sensors, plus a unique three-way reject valve on the Pipeline X-Ray, makes this Fortress range among the easiest and fastest to sanitise. All drive motors are located within the mechanical side of the cabinet, preventing cables from getting wet and damaged.

GEA

Hall 3 Stand E46–E54

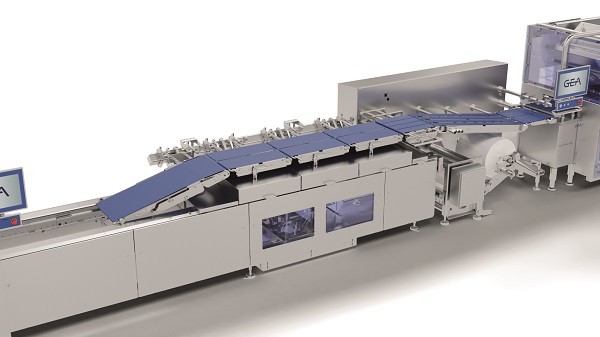

GEA OptiRobot 6000 robot

Technology group GEA will be at interpack itd innovations and demonstrate its engineering expertise in the fields of meat, meat alternatives, cheese, bakery, confectionery, and pastry products, including packaging solutions, robotics, and advances in digitalisation.

Highlights:

- A new electric oven and a retrofit kit for the conversion from gas to electric heating, which provides a carbon-neutral and efficient production process.

- A pre-dryer for pasta. Maximising air exchange at the product increases energy efficiency.

- A multi-purpose gelatinizer is an all-in-one machine that combines the functions of the xTru-Former and the xTru-Cooker. The machine has the advantage of a smaller footprint and a lower energy consumption.

- In belt loading systems, the OptiLoader family will be presented to the market for the first time.

- The GEA OptiRobot 6000 robot enables differently shaped portions (stacked, shingled, overlapped, etc.) to be loaded into a packaging machine with any kind of laying pattern fully automatically.

- The GEA OptiBuffer buffering system. In a slicing line, the reloading times of the slicer cause gaps in the product flow. The solution is a high-performance buffering system, with the help of which picking capacities of a robot system are effectively and exclusively used for inserting good portions into a packaging machine. GEA V-Packer IM-IV, a new vertical packaging solution for particularly fragile products in the pastry and bakery sector.

Heat and Control

Hall 14, Booth 14A56

The new FastBack 4.0 is a circular to linear drive horizontal motion conveyor which will offer unprecedented performance to food processors. A key feature is its new drive mechanism — which uses rotational (circular) drive motion to produce a horizontal (linear) motion. The innovative design uses circular-to-linear drive efficiency — to convert rotational motion into pure horizontal motion — while also supporting the vertical weight of the pan.

Heat and Control’s On-Machine Seasoning (OMS) system provides the industry’s most efficient and uniform coverage and can apply different seasonings — at each packaging station — without cross contamination.

For seasoning, the RSS uses a combination of a patented dynamic AccuFlavor™ Tumble Drum, the Modular Dust Collection System, and the advanced FastBack 260E-G3 into one compact, cost-efficient, standalone unit designed to overcome seasoning challenges at the weigher. Ideal applications for this system include potato chips, snack foods, crackers, torilla chips, nuts and trail mix.

Highlights:

- FastBack Lift and Tip — feeding into Ishida Multihead Head Weigher and Inspira Snack bagmaker

- FastBack 4.0-100

- OMS system

- Spray Dynamics - Continuous Mixer with Dual Drive & Uni III

Ishida Europe

Hall 14, Stand 14/A40

Ishida Europe will focus on its areas of expertise: weighing technology, quality control solutions and end-to-end packing line solutions to meet the specific needs of the fresh food and snack food sectors.

Highlights:

- The introduction of the Ishida CCW-AS, the company’s 11th generation of multihead weighers, which has been designed to offer the best weighing performance to further increase Overall Equipment Efficiency (OEE), particularly for more challenging applications, while at the same time delivering significant energy reductions.

- The Ishida IX-PD top of the range X-ray inspection system incorporates new sensor and image processing technology to achieve the highest level of detection sensitivity.

- The QX500 breaks new ground in terms of both its performance and environmental benefits, having been developed following detailed feedback from Ishida’s global customers and partners.

- A complete snacks packing line for pillow packs comprises an Ishida 14-head multihead weigher and Inspira rotary bagmaker, together with a new TSC-AS seal tester and new ACP Automatic Case Packer.

The “Sentinel” Industry 4.0 software combines machine performance monitoring with comprehensive data capture and in-depth analysis.

KHS Group

Hall 13 Booth A31

The KHS Group presents its portfolio of resource-conserving systems aimed at promoting circular economy.

Highlights:

- The tried-and-tested Nature MultiPack (NMP) machine is a prime example of the company’s pioneering packaging systems. This secondary packaging joins beverage cans or PET bottles together to form stable packs with just a few dots of adhesive – without any additional outer packaging necessary.

- To determine which style of packaging has which impact on the climate and whether a conversion for a stretch blow molder, for instance, has a positive effect on the carbon footprint or not, KHS has developed a number of carbon calculator tools. This free service has been developed together with the Hamburg Institute for Environmental IT, a leading independent international software developer for material and energy flow analyses.

- The Innopal PLR high-performance palletizer combines the benefits of low-feed machines with the capacities provided by palletizers with a high infeed. With the help of robots, this machine processes up to 625 layers per hour which amounts to a nominal capacity of 135,000 cans an hour depending on the can diameter. This machine can palletize PET containers and glass bottles.

Mettler-Toledo Product Inspection

Hall 11 stand A60

Mettler-Toledo’s solutions are positioned to help food manufacturers tackle the increasing need for digitalisation in the marketplace, as well as helping combat rising manufacturing costs. Their stand will have areas dedicated to checkweighing, metal detection, x-ray inspection, vision inspection, track & trace and combination product inspection systems, in which more than one product inspection technology is integrated within a single frame.

Highlights:

The M31R StandardLine metal detection is suitable for dry and wet applications and the M33R GC and M34R GC PlusLine metal detection systems offer a step-change in performance and sensitivity for dry or deep frozen and wet or metalized film-packed products inspected via a conveyor.

The X2 platform is designed for the inspection of small and medium packages with a belt width of 300mm and 400mm. X-ray inspection solutions within the platform are positioned to consistently deliver high performance detection capabilities for ensuring the safety and quality of food products.

Retailer-recommended Automatic Test System (ATS) for throat and gravity fall systems. Visitors will be able to discover how this award-winning innovation (Innovation Award for Quality Health, Safety and Environment, CFIA Show 2019) can increase operator productivity.

V13 Flat Pack Label Inspection System which performs inspection from the bottom up with a unique line scan camera, to inspect labels on the underside of flat packs at speeds of up to 300 packs per minute.

Advanced checkweighers featuring the new FlashCell™ EMFR technology, enabling precision weighing at speeds of up to 800 packs per minute; washdown checkweighers for harsh production environments that support intense and frequent cleaning whilst offering reliable accuracy.

MULTIVAC

Hall 5 Stand A23

MULTIVAC’s practical and needs-based solutions for packing small and medium-sized batches, as well as complete processing and packaging lines for the food industry will be showcased at interpack.

Highlights:

- For the food service sector, the R 085 e-concept thermoforming packaging machine is an entry-level model that can run sustainable materials as well as conventional flexible and rigid films. At interpack, the R 085 e-concept will be shown in conjunction with a Handtmann dosing system, which is used to dose food directly into the thermoformed packs.

- The standalone R 105 MF thermoforming packaging machine is an entry-level model for packing steaks or salmon cuts, in MultiFresh™ vacuum skin packs

- Space-saving, free-standing T 255 traysealer which enables many different types of tray packing to be produced on the one machine in small and medium-sized batches. The machine can be converted with just a few hand movements from producing MultiFresh™ packs to MAP packs.

- The T 305 is MULTIVACs’ smallest fully automatic traysealer and it can accommodate formats from one to four tracks. Recently it has also become possible to have PaperBoard applications and MultiFresh trays with 50 mm product protrusion.

- With its B 425 compact chamber belt machine, MULTIVAC is showing a model, which offers a very high output, particularly when packing smaller products such as ham, cheese, poultry and fish.

- The W 500 universal flowpacking solution which offers a high level of flexibility for packing a wide range of food products, and it supports the use of sustainable films and paper-based materials.

Paul Leibinger GmbH & Co. KG

Hall 8B Stand D26

Leibinger will be presenting an all-new coding & marking system at the interpack, aiming to raise the benchmark and promising a new era in the marking of, for example, best-before dates and other codes on a wide range of materials. “Especially in the case of cost-sensitive applications, such as in the F&B sector or in the Fast Moving Consumer Goods (FMCG) segment, it is decisive that the marking runs smoothly and without any interruptions. We have developed an entirely new Coding & Marking System that delivers exactly what it promises: absolutely worry-free printing,” reveals Christina Leibinger, CEO of Paul Leibinger GmbH & Co. KG.

Romaco

Hall 16 Stand D22

Romaco showcases its latest technologies for granulation, tableting and film coating as well as filling and packing solids, powders and liquids. With its one stop solutions for the pharmaceutical, nutraceutical, food, cosmetics and chemical industries, Romaco covers the entire process chain from powder processing to the finished pallet.

Highlights:

- MicroRobot 50 microdosing machine from Romaco Macofar is an ultra-flexible, high-tech solution for filling high-potency and cytostatic powders and liquids.

- Unity 600 blister line from Romaco Noack with up to 45% energy savings. This double-lane, high-speed line achieves a maximum output of 600 blisters and 350 cartons per minute and enables flexible processing of blister packs up to 145 mm long and 90 mm wide.

- IGL integrated granulation line from Romaco Innojet used to manufacture good quality granules for tableting.

- The KTP 720X double-sided rotary press from Romaco Kilian is now also available with a segment turret for up to 30% more performance. The new configuration with five segments and up to 115 punch stations paves the way for a maximum output of up to 1,380,000 tablets per hour.

- The KTP 1X R&D tablet press from Romaco Kilian is a single-stroke press designed as an all-in-one instrument for R&D activities. It is suitable for pressing mono-layer, bi-layer and triple-layer tablets as well as tab-in-tab formats.

- TP R Optima tablet coater from Romaco Tecpharm genuinely processes any batch size from 10% to 100% in a single drum and achieves optimum coating results no matter how small the filling volume – fully automatically without any manual adjustments.

SEALPAC

Hall 5 Stand F38

Choosing the motto "GO sustainable!" for interpack, SEALPAC will demonstrate show how its flexible, semi-automatic traysealer can package products in small quantities, as well as how its high-output traysealers and thermoformers are fully prepared for Industry 4.0.

Highlights:

- The all-round, semi-automatic M-Flex traysealer can be used by craft workshops, small business startups, laboratories, test kitchens and catering suppliers to produce packaging solutions in a small space and with only short set-up times. The traysealer processes all prefabricated packaging materials, such as plastic, foil and cardboard, with the highest degree of precision to produce secure and attractive packaging, ranging from standard solutions to innovative SEALPAC packaging concepts like FlatSkin®, FlatMap®, TraySkin®, EasyLid® and more.

- The SEALPAC Amax-series features a low-wear, low-maintenance design and are driven by high-quality servomotors that allow for smooth production runs. In addition to conventional modified atmosphere or TraySkin® packaging, these traysealers produce resource-saving solutions.

- Machine monitoring – by using the OPC/UA, the company’s equipment can easily integrated into line control software. This allows customers to see in real time if the machine is running, in stop, in error, or waiting for up- or down-stream equipment.

Sidel

Hall 13 Booth B47

Sidel is expanding its palletising range with the introduction of the high performing RoboAccess_Pal S palletising unit that combines the best of cobotics and robotics. The machine delivers improved agility, operability and compactness to the Food, Home, and Personal Care (FHPC) market segments.

The machine delivers speeds of up to 12 cycles per minute and enables a case payload of up to 25kg while ensuring a fast return on investment, typically of one to two years. It also offers a new level of compactness with a footprint of less than 12m² for two stations with a significant pallet height of 1700mm.

Available only in 10 weeks, RoboAccess_Pal S is embedding three new patented features to provide an even higher level of agility, operability, and compactness. A light-weighted carbon fibre and 3D-printed clamping head helps deliver higher payload capacity and overall machine footprint reduction while handling a wide range of secondary packaging.

Sollich KG

Chocotech GmbH

Hall 3, Stand F20

Enromat® enrobing machine

Sollich KG is one of the leading manufacturers for machines for the confectionery industry at interpack where it will underline the efficiency and easy clean features of its equipment.

Highlights:

- The Thermo-Flow® cooling tunnel segment features a wheel-out heat exchanger for convenient cleaning. The mobile belt washing unit with integrated hygiene washing drum guarantees practical handling when cleaning the conveyor belt and additionally ensures that no foreign particles can get onto the products during the cleaning process.

- The Turbotemper® a machine for chocolate pre-crystallisation comes with a complementary cleaning device to allow an easy and quick mass changeover.

- The Enromat® enrobing machines have Clean in Place (CIP) system – a mobile washing station and accessories

- Together with other suppliers of confectionery machines, Sollich KG founded the company SweetConnect GmbH. On this platform, users can manage their integrated production machines at a glance. Documents such as operating instructions, spare parts catalogs and cross-manufacturer maintenance managers are just some of the basic functions made possible with the help of SweetConnect®.

- With "Fast Lane" remote maintenance system, data from the application process are transmitted to optimise services and increase machine availability.

- Sollich Tempergraph® is a device that allows automatic measuring of the degree of temper in the chocolate. The Tempergraph® can be installed within the enrobing machine. In this constellation an adequate determination of the tempering degree can be achieved – namely directly before enrobing.

- The Miniconbar® system for the production of bar products

- Sollcocap® sandwich system for the production of sandwich products

Syntegon

Hall 6 stand A31

Syntegon showcases its line expertise in horizontal packaging solutions for cookies and bars. The Syntegon IDH is at the heart of a line which flexibly packages cookies and crackers in trays and flow wraps made of mono-material. A new pick-and-place technology with integrated linear motors handles products gently. Linear motors feature in various feeding modules in both lines to prevent product damage during handling and boost flexibility.

Sustainable glue-free carton forming

After packaging, the integrated Sigpack TTM1 topload cartoner takes over the bars for secondary packaging. The intelligent PFI product feeding module is based on linear motor technology and identifies the position of individual flow wraps before gently and precisely loading them into the grouping chain. This eliminates the need for additional mechanical parts such as side guides that could damage the paper flow wraps. Both the omitted format parts and the overall changeover concept of the TTM1 ensure quick and easy format changeovers along the entire line.

“With the new lock-style forming station, Syntegon further adds to its sustainable packaging initiatives. Cartons are formed without using hot-melt glue. This not only protects the environment, but also reduces the system’s energy consumption, minimizes cleaning efforts and sources of malfunction – and, last but not least, saves on consumables,” explains Andreas Schildknecht, Product Manager at Syntegon. The lock-style module is also available as a retrofit kit for many Syntegon cartoners.

The new wireless HMI 4.0 allows operators to control and monitor the entire line via a single interface. In case of malfunctions and maintenance work, they can immediately access all the important information and instructions to restart the line as quickly as possible. Tool-free format changes on all line components further reduce downtimes.

Interface with digital services

Synexio contributes to the optimal monitoring of the equipment: The new cloud-based software solution collects, evaluates and visualises machine and production data.

Technophar Equipment and Services S.R.L

Hall 15 C51

The SGM612NextGen® is the latest next-gen fully integrated soft gel encapsulation machine from Technophar. This standalone unit integrates with current soft gel processing equipment and is suitable for laboratories, research institutions, food factories, nutraceutical facilities, and other related industries.

The commercial scale model features an integrated electrical panel and chiller with improved parts changeover. Modular in design, it is also easy to maintain and clean. Servo motors and electronic gearing further increase reliability and reduce downtime, while user-friendly programmable logic controller (PLC) and touchscreen user interface provide easy access to and control over all the process parameters.

Toyo Printing Inks Inc.

Toyo Ink Europe, N.V.

Hall 18, Stand F16

Under the banner of “Packaging Innovation for a Sustainable Future,” the Toyo Ink Group will showcase solutions that can help brands and packaging converters make the transition to a circular economy. This entails functional inks and coatings, adhesives and other specialty materials that help to reduce the amount of plastics used in packaging and that support the shift from multi-material to mono-material packaging.

Highlights:

A new line-up of functional coatings that can replace the plastic in paper or film packaging as part of the growing drive toward increased recyclability. Product highlights include oxygen barrier coatings and transparent UV-block coatings RV-20010 that serve as a substitute for aluminum in flexible packaging structures.

Toyo Ink Group will be showcasing an updated line of low-energy, low-VOC ink systems for sensitive packaging and label printing applications. Steraflex™ LED Food is the low-odour, low-migration flexo ink engineered to be food-grade compliant in accordance with Swiss Ordinance.

The LP-9000 Toyo Life Premium Food LO/LM series of sheetfed offset inks are INGEDE-certified for deinkability, and engineered and manufactured in accordance with EuPIA guidelines and Good Manufacturing Practices standards.

A total solution approach to metal package production, includes Toyo’s internal can coatings that are free of any intentionally added bisphenol A (BPA-NI) and fully compliant with food contact regulations.

Winkler und Dünnebier Süßwarenmaschinen GmbH (WDS)

Hall 1, B66

ConfecVARIO

With the theme, “WDS – Home of Confectionery Diversity: Production Lines for All Capacity Requirements”, Winkler und Dünnebier Süßwarenmaschinen GmbH (WDS) will show interpack visitors customised production lines for chocolate, gum and jelly, toffee, fondant and hard candy.

Flexible machine concepts will be presented at the stand: A ConfecECO in jelly configuration, the new, versatile ConfecVARIO configured for chocolate production and a laboratory depositor for special hygienic demands.

At the 650 m², multimedia-equipped trade fair stand, visitors can also learn about the WDS “sweetOTC” division, which specialises in the product development and production of innovative OTC confectionery or supplement dosage forms. With new, specially designed WDS production plants, companies can expand their product portfolio and thus open up new growth markets.

Another topic at interpack will be Starch-free WDS production technology under GMP conditions. For this, WDS has developed new and innovative plant technology for depositing and demoulding with polycarbonate moulds.

(Updates will continue)

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login