AS SOUTH Africans work longer hours to meet the challenges of a straining economy, never has convenience been more of a requirement. This is especially apparent in the choices they make in food and beverage. Pasta is one of the best solutions to the increasingly busy lifestyles of consumers due to its ease of preparation, versatility and wide availability.

Tucked away in a modest suburb, alongside one of Johannesburg’s busiest roads is the La Pasta Delizia pasta factory. Its owner and factory manager Chris Christopher who is a South African born, Cypriot Greek talks to Food Manufacturing Journal – Middle East & Africa about the company.

How did you get involved in the pasta business?

I met Italian-born Sergio Lorenzato when we worked in a bank together and he introduced me to Franco (also Italian-born) who was making pizza at his restaurant. I joined Franco to work in the Norwood restaurant called La Lampara when I was about 30 years old and remained there for about 10 years. Norwood is a suburb of Johannesburg neighboring Orange Grove.

In 1994, Sergio and Pino (Franco’s brother-in-law) bought the business, machines and other operational supplies from BettaFresh situated in Wynberg, an industrial area of Johannesburg. In 2005 La Pasta Delizia relocated to bigger premises in Orange Grove, a hybrid area, part residential, part commercial. This was to facilitate expansion and ensure no further disruption to manufacturing processes.

How big is the factory?

The factory is about 400 square meters across two floors. We have a tight operation and employ just 14 people but there are no shortcuts. Everything is done according to rigorous industry standards and although our team is small, everybody is meticulous about processes.

Does the company offer most types of pasta? Which ones sell well in the local market?

We sell fresh lasagne sheets in quantities of 400kg to 600kg per week to customers who make up their own ready-to-eat lasagne dishes. Our heat-and eat dishes that are most popular are beef lasagne, panzerotti with rosa sauce and melinzane parmigiana. They are packed in 400g, 800g and 2,5kg portions.

In the dry lines we make fettuccine, fusilli, gnocchi, macaroni, rigatoni, and Ninni shells.

What would you say is special about the pasta?

Our meals are tasted and tested by our customers. We guarantee freshness and rely on traditional homemade Italian recipes. We make Napolitan, bolognaise, Alfredo, Puttanesca and pesto sauces and we will make up any recipe to a client’s specifications.

Tricolor pasta

How are new trends influencing your product range?

We produce a gluten-free variant in fettuccini, fusilli, gnocchi and macaroni. The main ingredient in the gluten-free product is rice flour and we make it in bulk and outsource the packaging. In the gluten- free line we make about one ton per month.

We also make a whole wheat fettuccine and rye macaroni. We have tomato and spinach flavored pasta in some of the dry lines such as gnocchi shells, fettucine, taglione, macaroni and fusilli. Most of our pastas are available with egg as part of the ingredients or egg free. And all our pasta is free of preservatives.

Although many consumers may have changed their food preferences, traditional meals are still in demand. Sometime a restaurant will ask for a special filling and we do our best to make it up to their specifications.

Who were among the first clients of the La Pasta Delizia?

We started out with Pick n Pay one of the country’s largest and oldest supermarket chains. We supplied a variety of filled pasta for the chain until about 2005. The group was undergoing an image revamp which included changing their logo and all their packaging. They decided they were not happy with our product and raised questions about using powdered eggs in the production process and so insisted on fresh eggs. We changed their production line to run with fresh eggs but we still could not satisfy them and we lost their business.

How did the company move on after Pick n Pay?

We are largely out of retail supply with the exception of a few small independent supermarkets. We now supply mainly to the catering industry, restaurants chains, central kitchens and wholesalers. An order can be between 80kg to 160kg in a week. A wholesaler can take up to 200kg of fresh pasta in a week or sometimes one ton of macaroni.

One of our customers has a canning operation. We supply ravioli, and tortellini with beef and chicken fillings in batches of about 250kg.

Who are the company’s competitors?

The major pasta makers in South Africa are FG La Pasta, MG Pasta, Pasta Gallo and Fattis & Monis.

What is the production capacity at the factory?

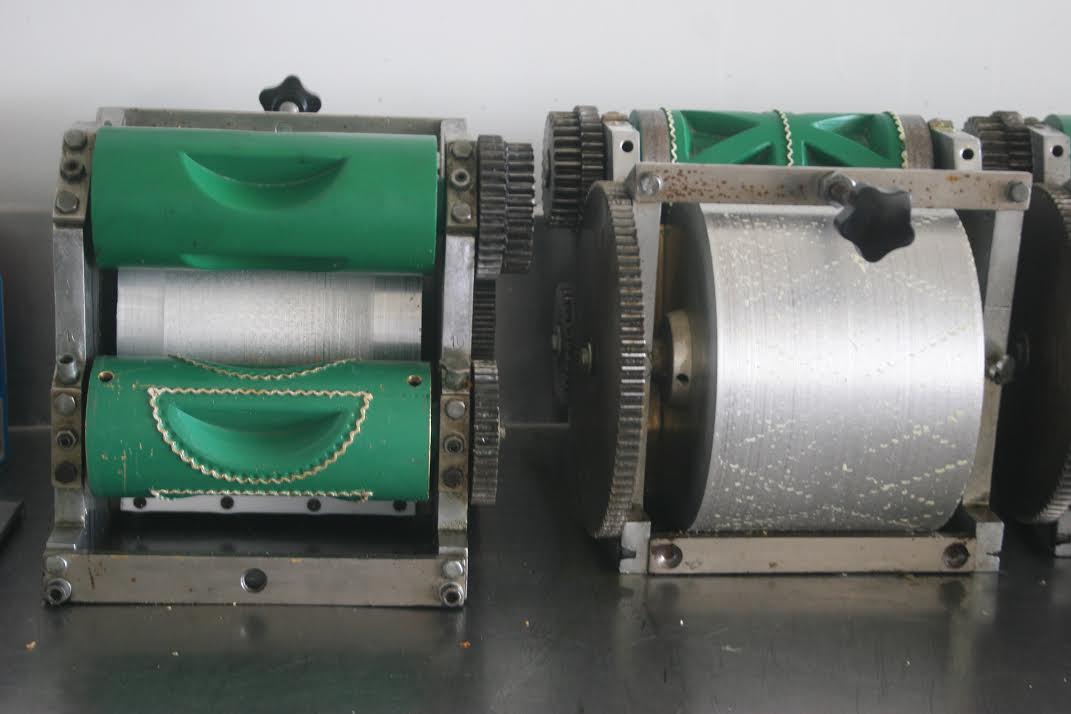

We have two pasta making machines in the factory. One is an extruder that has different dies for making the dry noodles and the fresh lasagne sheets with an output capacity of about 100kg per hour. The sheets are pasteurized for three minutes at 70 degrees or higher to dry.

The other machine makes the pasta for the fresh filled pasta. In addition there are pasta forming machines for the different types of filled pasta such as ravioli tortellini, panzerotti, girasole and triangoli. The output capacity of these machines is about 40 to 60 kg per hour.

The fillings are prepared and funneled through a stainless steel cup into the pasta on the pasta forming machine or, on another type of machine, the filling is pushed into the pasta via a wormgear on the pasta forming machine. The filled pasta goes through a steam pasteurization process at 75 degrees for three minutes.

Pasta forming machines at Delizia

Are your sales affected by seasonal changes?

Well people eat more in winter. When the cold weather sets in nobody wants to go out but when they get used to the weather they start eating out again, and then our fresh pasta sales increase.

What lies ahead for the pasta-making industry in South Africa?

Traditionally pasta has appealed to the country’s white middle class. In the past few years we have seen interest from an emerging black market which has been buying macaroni. Macaroni has already proved to be popular and we expect the market to experiment with other lines.

Also with a more demanding lifestyle customers will prefer meals that are easy to prepare. Not only that, pasta remains an affordable meal and as food prices tend to escalate, we expect the demand for pasta to increase.

adidas superstar damen glitzer silber

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login