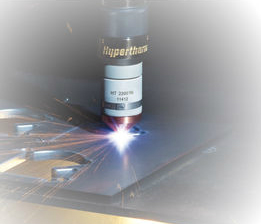

U.S.-based industrial cutting solutions specialist, Hypertherm, produces an array of products which includes waterjet, plasma, and laser technologies. The 100% associate-owned company was founded in New Hampshire in 1968. Israel Gonzalez recently joined the Hypertherm Asia-Pacific team as Regional Director, and will look after the company's operations in Australia, Indonesia, India, Japan, Malaysia, New Zealand, the Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. Israel recently relocated to Singapore and his previous role was the Country Manager of Hypertherm Mexico. We recently sat down with him to discuss Hypertherm's edge and his plans for expansion in the region.

IMNA: What kinds of technologies and services do you offer your clients?

Gonzalez: We are the trusted advisors who give our customers access to the best available technologies for their industrial cutting needs. So this covers recommending the best technology for their particular applications, and future requirements, in order to help them grow their business in the most profitable way.

IMNA: What new perspectives do you give to your new role at Hypertherm?

Gonzalez: That's a great question! Hypertherm Asia-Pacific has been greatly managed by my predecessor, Mr Soo Kam Tatt. He started the operations here almost from scratch and grew it to more than ten times its original size in less than one and a half decade. Moving forward, what we are looking for is to expand our business to uncovered lands like Indochina, and islands like Indonesia and the Philippines. We will also continue to strengthen and grow our current strongholds in Australia, India, Japan, Malaysia, New Zealand, South Korea, Taiwan, and Thailand.

In addition to that, we want to implement very aggressive after-sales strategies. So far, our company has been doing business for new machines but we know that the after-sales market is a growing source of revenue. Renewing of the machines and spare parts is becoming a very important part of our business here, so that will be a new addition to our strategy.

IMNA: In your opinion, what are some big challenges that manufacturers in Asia are currently facing and what will Hypertherm offer to help solve these solutions?

Gonzalez: Well, the focus of our customers is not on cutting. They produce finished goods. Our main mission is to provide customers with the best technologies so that they can forget the problems associated with the cutting process. Our solutions will help them to concentrate their efforts on what they do best – manufacturing and delivering finished goods like heavy construction equipment, ships, or buildings.

IMNA: Can you tell us about the profile of some of your clients? How have your clients benefited from using Hypertherm technology?

Gonzalez: I'm going to talk about some of our customers in the shipbuilding industry, because they are some of our biggest customers in Asia-Pacific. If you look closely at a ship, every single part of the structure is made of metal. To make a ship, they start with just flat square metal pieces. The engineering efforts to do all of the design require tons of hours and money. Our power supplies, software, and automated equipment are designed to help these engineers reproduce their drawings on the sheet metal easily, optimise material utilisation, and produce cut parts with high quality. After that, they can just assemble the pieces to build the ship. As you can see, cutting the metal is the very first process of the whole operation. Without this step, the rest of the shipbuilding process cannot continue. This is a very strategic and delicate part of the manufacturing process. We help our customers to put more of their attention to the rest of the operations.

IMNA: How involved is the company, from a manufacturing and marketing perspective, in Asia?

Gonzalez: We don't actually manufacture our products here in Asia. From a marketing perspective, we have evolved from basic marketing tactics like trade shows and brochures, to a more integrated marketing strategy. These include corporate branding, marketing insights, customized partner programs, customer relationship management, B2B strategies, digital strategies, social media, and communications.

IMNA: So where does the manufacturing take place?

Gonzalez: We have operations in the United States of America. Our main factory is located in Hanover, New Hampshire, our software facility is in Lockport, New York, and our waterjet manufacturing facility in New Brighton, Minnesota. We also have another factory located in Italy for laser consumables.

IMNA: Hypertherm is 100% associate-owned. What does that mean and how does this give your company an edge?

Gonzalez: This is one of the characteristics of Hypertherm that we are most proud about. Hypertherm’s founder started the company 46 years ago with a very humble beginning and little resources, and the company grew to a point where many people wanted to invest in us. The first thing that we did to secure our private investment was to make 40% of the shares of the company employee-owned. So every single employee became a partial owner. The majority of the shares still belonged to our founder Mr Dick Couch.

Our company sales are growing at above industry rates, and our balance sheet is financially sound. We have also developed very strong brand awareness in the industry. Many corporations and companies have been knocking on our doors wanting to buy over Hypertherm. The only way our founder believed we could secure our future and keep our original values intact was to sell the company to the employees. So what we did was, we bought the remaining 60% of the shares from Mr and Mrs Couch. As a result, in December 2013, the company became 100% owned by the employees.

IMNA: What are your plans for the company for 2015 and beyond?

Gonzalez: We have a very aggressive territory expansion strategy, especially in regions like Indochina, Indonesia, Oceania, and the Philippines. At the same time, we also want to maintain our dominance in the current markets.

In terms of product expansion, we are investing heavily in R&D to develop new technologies and improve existing products. We are adding new waterjet technologies and new manual handheld plasma-cutting equipment, and we will focus on marketing our specialised consumables for specific applications.

In terms of infrastructure expansion, we have plans to invest in newer offices and cutting technology centres, hopefully within the next two years. We will also be increasing the associates head count to cover those areas which I just mentioned.

Zoom Lebron XI 11

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login