Exhibitors' Showcase Part 1 presents the machinery, technologies and equipment on exhibit at K 2022, with product description and contact details of exhibitors.

Addex: Cooling technology

Addex Inc. launches its latest iteration of its patented Intensive CoolingTM technology, the “Short Stack.” It typically delivers a 25% increase in output over the company’s original Intensive Cooling “Down-on-the-Die” version, which already improves output by 10-15% over conventional dual-flow air rings. Intensive Cooling is Addex’s unique approach to cooling the bubble which changes the common aerodynamics of present-day blown film air rings to dramatically increase stability and output. Addex has successfully added additional high-velocity air streams to the traditional single, high-velocity “main lip” air stream common to all air rings. In the new Short Stack configuration, the bubble is pulled through a circular enclosure located between the die and air ring that naturally pulls the bubble into an oversized air ring which further increases output.

Addex Inc.

Tel: +1-315 331 7700

E-mail: addex@addexinc.com

Website: www.addexinc.com

Booth: 17C41

Agr: Automated blowmoulder

Agr presents Process Pilot+™, which reflects the latest advancements in automated blowmoulder control for PET bottles. Built upon Agr’s iconic Process Pilot automated blowmoulder management system, the Process Pilot+ incorporates a patented technology that significantly improves blowmoulder efficiency and profitability by enabling operators to optimise the blowmoulder based on performance, energy efficiency or operating costs. Robotic automation combined with precision measurement for plastic containers is another highlight. Featured will be an automated measurement cell that mates Agr’s Gawis 4D measurement system with a robotic handling system for hands-free bottle or preform measurement.

Agr International, Inc.

Tel: +1-724 482 2163

E-mail ddineff@agrintl.com.

Website: www.agrintl.com

Booth: 11C40

Arburg: Injection moulding

Arburg is committed to making its contribution and presenting solutions for global issues of sustainability, the circular economy and carbon reduction through its "Plan A" message that communicates clearly that there can be no 'Plan B' when it comes to resource conservation, the circular economy and carbon reduction – following the motto of the sustainability movement. At K 2022, Arburg illustrates how highly networked, digitalised manufacturing helps to conserve resources and increase production efficiency. It is all about the synergy between the circular economy and high-tech with the help of targeted digitalisation. A total of eight hydraulic, hybrid and electric Allrounders with a clamping force of between 350 and 6,500 kN and two Freeformers for industrial additive manufacturing are on show.

ARBURG GmbH + Co KG

Tel.: +49 (0)7446 33-3463

E-mail: presse_service@arburg.com

Website: www.arburg.com

Booth: 13A13-1 – B13

BB Engineering: Extrusion, PET recycling

As a sub-exhibitor of Oerlikon, BB Engineering presents itself as an expert in extrusion, mixing and filtration as well as an innovator for PET recycling with the VacuFil and VarioFil R+ systems. BB Engineering has been focusing its development work increasingly on recycling technologies for several years. In addition to extruders, filters and mixers that are suitable for both recycling pro-cesses and the processing of recyclate, BB Engineering offers a complete PET recycling plant called VacuFil. With VacuFil, BB Engineering has developed an innovative and unique PET LSP recycling process. The process combines gentle large-scale filtration and targeted IV regulation for consistently outstanding rPET melt quality.

BB Engineering GmbH

Tel: +49 2191 9510 100

E-mail: sales@bbeng.de

Website: www.bbeng.de

Booth: 1D10

Brabender: Testing/laboratory equipment

Brabender GmbH & Co. KG presents solutions for quality testing and the development of sustainable plastic and rubber products on a laboratory and pilot plant scale. In addition to modular torque rheometers with measuring kneader and extruder attachments, this also includes compact extruders of various dimensions as well as devices for special measuring applications in the plastics industry. Another highlight shows current projects with partners from research and industry in which the Brabender devices are used including the extrusion of sustainable films from algae or the determination of carbon black from recycled car tyres using the C absorptometer. For K 2022, Brabender also offers the MetaStation 8 stationary drive together with MetaStation 16, known as the successor generation of the well-known Brabender Plasti-Corder Lab station.

Brabender GmbH & Co. KG

Tel: +49 203 7788-129

E-mail: nicole.kuska@brabender.com

Website: www.brabender.com

Booth: 10A14

Brückner Maschinenbau: Sustainable film production

Brückner Maschinenbau is sticking to its ambitious goals for further increasing efficiency in film production in addition to the developments for the rapidly developing circular economy. This means decreasing raw material use, ever lower energy consumption and "zero waste" in film production. At K 2022, Brückner Maschinenbau presents efficient production of BOPP and BOPET, the benchmark in production speed has so far been around 600m/min. It also presents BOPA film line types with up to 80% more output – based on an increase in production speed from 220m/min to 350m/min and a line widening from 6.6m to 7.4m. Another exhibit is the battery separator foils and capacitor foils where in these segments, the previous (already exclusive) line width of 5.5m is being increased step by step to over 6m and the associated increase in output of over 20.

Brückner Maschinenbau GmbH & Co.KG

Tel: +49-8662 63 9278

E-mail: karlheinz.weinmann@brueckner.com

Website: www.brueckner.com

Booth: H3C90

Chen Hsong: Injection moulding machines

Chen Hsong highlights its JM168-MK6.6, a new offering from the same team who developed the industry-leading MK6 series. Another model is SPEED-PACK II 400, which redefines efficiency. Chen Hsong develops the revolutionary SPEED-PACK series of packaging machines based on its highly-popular SPEED series of high-speed injection moulding machines. Its secret lies with Chen Hsong’s remarkable Precision Hydraulics™ technology (developed in Japan) that enables extremely high speed, but silky-smooth, mechanical motion while maintaining superb sub-millimetre precision.

Chen Hsong

Tel: +852 2665 3222, +49 15204695827

E-mail: marketing@chenhsong.com , europe@chenhsong.com

Website: www.chenhsong.com

Booth: 13B43

Chen Way: Co-extrusion blow moulding machine

Chen Way Machinery is well-known for its 20L three-layer blow moulding machines. Three-layer co extrusion blow moulding machines are the most popular choice for the edible oil export countries, and their productions range from 5L to 30L jerry cans. The composition for three-layer products is usually as follows: 1) The outer layer is composed of 15%-20% virgin material and masterbatches; 2) The inner layer is composed of 15%-20% virgin material; 3) The middle layer is a combination of 60%-70% cost-effective regrind material and CaCO3 (no more than 30%) which reduces material cost by 10-12%.

Chen Way Machinery Co., Ltd

Tel: +886-6 243 4077

Fax: +886-6 243 4071

E-mail: service@chenwaym.com

Website: www.chenway.com.tw

Booth: 13C04

Cheng Mei: Thermoforming machine

Cheng Mei Machine Co., Ltd., established in 1984 in Taiwan, specialises in thermoforming machine and punching machine design and manufacture. Its CM-100 series thermoforming line has low energy consumption, high productivity and easy operation/maintenance features. Cheng Mei has its own R&D and customer service team for supplying technical support in order to offer high quality and efficient after-service. Currently, the company is able to manufacture more than 50 machines annually to export to all over the world.

Cheng Mei Machine Co., Ltd.

Tel: +886-3 307 6309

Fax: +886-3 390 9519

E-mail: cheng-mei@cheng-mei.com.tw

Website: www.cheng-mei.com.tw

Booth: 3G65

COLINES: Extrusion line for stretch film production

COLINES will be showcasing one of their latest generation ALLrollEX 3000mm 6-up, the world renowned extrusion line for stretch film production. The line will be running daily and performing a very specific recipe developed in cooperation with COLINES’ traditional partner for stretch film, ExxonMobil. COLINES is also showcasing their ALLwrapper, the innovative solution for any bundle wrapping with stretch film in place of shrink film. COLINES booth also hosts one of the bestseller lines by NO.EL. who has recently joined Gruppo COLINES Holding.

COLINES SPA

Tel: +39 032148 6311

E-mail: marketing@colines.it

Website: www.colines.it

Booth: 16A39

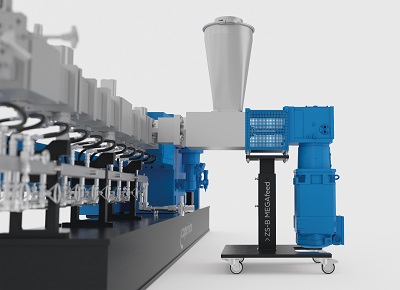

Coperion & Coperion K-Tron: Plastic recycling technology

Coperion and Coperion K-Tron are presenting a variety of new and ongoing developments at their booth that will markedly increase the efficiency of plastics compounding processes, help boost conscientious resource handling while at the same time achieving very high product quality. Exhibits encompass bulk solids handling, feeding, extrusion, and pelletizing, all representing Coperion’s advanced expertise in numerous plastics recycling processes such as chemical recycling, multilayer film recycling, and upcycling. Trailblazing new developments from Coperion, such as the ZS-B MEGAfeed side feeder, are also presented.

Coperion GmbH

E-mail: info@coperion.com

Website: www.coperion.com

Booth: 14B19

Davis-Standard: Extrusion and converting technology

Technologies from the Davis-Standard family of companies, including Davis-Standard, Maillefer, Brampton Engineering, Deacro and Thermoforming Systems LLC (TSL), are shown with an emphasis on customer profitability and performance. Visitors can experience continued developments in extrusion and converting technology focusing on a circular economy, energy efficiency, reduced power consumption and waste, as well as live demonstration of smart factory connectivity. Among the technology on exhibit are: Aftermarket Advantages that offer end-to-end service, parts, and line upgrades; DS Activ-Check™ platform; SHO Extruder (3.5-inch, 90mm); MXD Extruders; Model 4000A Crosshead; Extrusion Die 510A; Extrusion Laminator; and XP Express® AGT.

Davis-Standard

Tel: +1-860 650 3405

E-mail: ndenerley@davis-standard.com

Website: https://davis-standard.com/

Booth: 16A43

Diing Kuen: Multi-layer extrusion machine

The TK-HTRL 2500-5C-2 from Diing Kuen Plastic Machinery Co., Ltd. is a product of the company’s more than 25 years of experience in extrusion technology. The machine features: Layflat Film width of 1800 ~ 2400 mm, with film thickness : 0.030-0.2 mm; high-speed extruder output of 800 kgs/hr; manual screen changer; power-saving heating system; multi- layer extrusion die of flat superimposed type; auto winding unit that includes Tension Control System; Industry 4.0 Technical Services IIoT-capability. The machine is ideal for the production of agricultural film, stretch film and shrink film.

Diing Kuen Plastic Machinery Co., Ltd.

Tel: +886-5 221 7410

Fax: +886-5 221 7413

E-mail: diingkuen@hibox.hinet.net

Website: www.diing-kuen.com//

Booth: 16E71

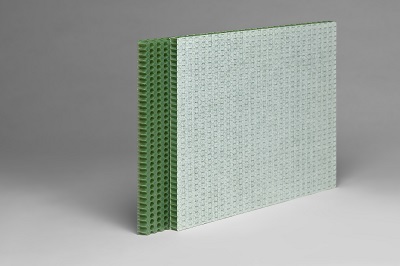

EconCore: PP honeycomb core

EconCore launches its innovations that are set to massively contribute to circular economy. The group, consisting of EconCore NV in Belgium and the German ThermHex Waben GmbH focusing on production of PP honeycomb core, just installed a new production line for lightweight honeycombs based on recycled PET (rPET). The new line is capable of production of RPET honeycomb core in widths up to 1.2m. At the same time, the unique design of the line allows for processing of other thermoplastic materials such as polycarbonate, polyamide or polyetherimide (high-performance-thermoplastics, HPT).

EconCore N.V.

Tel: +32-16 3810-60

Fax: +32-16 3810-69

E-mail: info@econcore.com

Website: www.econcore.com

Booth: 8AC37

ENGEL: Digitalisation, energy-efficient injection moulding systems

Conserving resources and energy has always been firmly anchored in ENGEL’s corporate philosophy. As an injection moulding machine manufacturer and system solutions provider, ENGEL is responsible for three areas: the overall efficiency of the injection moulding production cell, digitalisation of the injection moulding production processes, and processing technologies which support the circular economy. From servo-hydraulic, through hybrid, to all-electric, injection moulding machines by ENGEL are some of the most efficient on the market in their size and performance classes. The self-optimising injection moulding machine is an essential feature in digitalising the injection moulding processes. ENGEL iQ product family includes nearly ten smart assistance systems and ENGEL presents another system at K 2022 in addition to multiple machine exhibits.

ENGEL Machinery

E-mail: sales@engel.at

Website: www.engelglobal.com

Booth: 15C58

Frigel: Process cooling solutions

Frigel Group brings to K 2022 the main highlights of its portfolio of products tailored to the main plastic market segments, such as automotive, packaging, medical and all other sectors dedicated to the injection moulding of technical parts. New machine-side solutions have been designed to ensure the maximum profitability and quickest ROI for the processor, leveraging productivity, product quality and process repeatability improvements. These solutions are the result of 30 years of experience and successful stories of process optimisation, with a global organisation bringing not just process cooling expertise, but a vast know-how in plastic processing and technology dynamics. Driven by the fundamental purpose of “Engineering a more efficient and sustainable industry”, Frigel is also bringing some of its recent highlights in centralised system solutions.

Frigel Group

Tel: +39 049 970 3319

E-mail: marketing@frigel.com

Website: www.frigel.com

Booth: 11A66

Full Shine: Blow moulding machines

Full Shine Plastic Machinery, the leading manufacturer of blow moulding machines in Taiwan, has more than 30 year of experience in the plastic industry. Full Shine has established a complete company operation and has obtained certificates such as ISO 9001:2000 and CE, making it a certified provider of total solution for plastic moulding production. Full Shine is professional manufacturer of Blow Moulding Machine, Multi-layer Co-extrusion Blow Moulding Machine (2-6 layers bottle), and Accumulator-head Blow Moulding Machine.

Full Shine Plastic Machinery Co., Ltd.

Tel: +886-4 2276 5071

Fax: +886-4 2276 5070

E-mail: sales@full-shine.com

Website: www.full-shine.com

Booth: 14C28

KIEFEL: Modular automation concept

The new Kiefel Speed Automation (KSA) is based on a modular system. In addition to customer-specific automation solutions, with the KSA the company offers completely modular and therefore flexible standard automation for the KMD series, especially for the SPEEDFORMER KMD 78.2. The KSA is optimally matched to the KMD series and can be integrated into existing systems as well as into new machines. This allows the production of packaging with various modules to be automated and modernised. A KSA module forms stacks from partial stacks, e.g. of food trays. Another module is the carton erecting and closing unit. It removes cartons from box magazine, erects them, and if necessary, inserts a protective bag for hygiene packaging of the products.

KIEFEL GmbH

Tel: +49 8654 78 911

E-mail: communications@kiefel.com

Website: www.kiefel.com

Booth: 3E90

Kung Hsing: Multi-layer blown film production lines

KUNG HSING helps customers achieve 30% increase in blown film production. How is it made possible? Kung Hsing ‘s unique machine design provides multilayer machines with the capability to be left unattended; with production monitoring system that enables evaluation of problems and utilisation of production data to achieve greater precision, enhance efficiency, and increase production.

Kung Hsing Plastic Machinery Co., Ltd.

Tel: +886-5 237 4466

Fax: +886-5 237 6971

E-mail: ks.sales@kunghsing.com.tw

Website: www.kunghsing.com.tw

Booth: 16C18

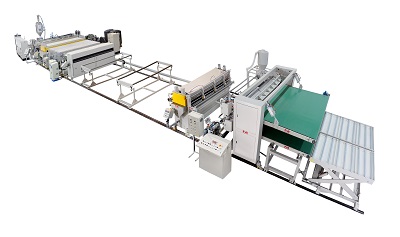

Leader Extrusion: PP hollow profile sheet extrusion line

A hollow sheet extrusion production line is suitable for the production of hollow plates of various specifications, special screw structure, control of technical parameters, stable setting equipment, and a precise temperature control system. The electronic control equipment effectively optimises the whole line operation and achieves high quality and high output. Widely used in architecture for light partitions, building material protection boards, and packaging for aquatic vegetable and fruit packaging boxes, turnover boxes, etc. In addition, PP hollow sheets are colourful, printable, and processable that are also widely used in stationery, card supplies, etc.

Leader Extrusion Machinery Company Ltd.

Tel: +886-4 2638 0888

Fax: +886-4 2638 0333

E-mail: leadertw.ex@leadertw.com

Website: www.leadertw.com

Booth: 14A58

MAAG: Die plate

MAAG Group’s acquisition of French tool manufacturer AMN DPI (AMN) is highlighted at K 2022, thus continuing MAAG’s growth as an integrated supplier of systems for the plastics industry. For the first time, a complete AMN Central Injection System (CIS) consisting of a 1500 mm diameter die plate with a central water injection and sword shaped knives are on display. CIS was designed to improve pellet cooling and ejection and is an effective solution for high melt index or peroxided polymers.

MAAG Group

Tel: +41-44 278 8349

E-mail: MaagChina@maag.com

Website: www.maag.com

Booth: 9A02

NXT: GRAN - new standards for efficient recycling

The NXT:GRAN enables the plastics processing industry to achieve true zero-waste production. It guarantees full value retention of the material and, thanks to newly developed technology, reduces labour and energy requirements to a minimum. The easy-to-use and easy-to-maintain NXT:GRAN relies on the patented NGR "One-Step Technology", which enables the reprocessing of plastic waste in a single step. In addition to the increased cutting performance in the shredder, the material feeding into the extruder has been optimised. Therefore a significant increase in output across the entire material spectrum has been achieved.

Next Generation Recyclingmaschinen GmbH (NGR)

Mobile: +43 (0) 664 8257590

E-mail: tobias.huber@ngr-world.com

Website: www.ngr-world.com

Booth: 9C21

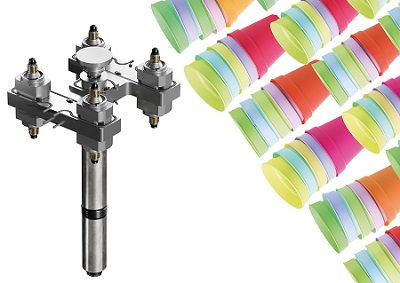

Oerlikon HRSflow: Hot runners

Oerlikon HRSflow focuses on an extensive range of hot runners tailored to small shot weights and the new Xp nozzle series for use in thin-wall injection moulding. Both support the trend towards greater sustainability by helping to reduce energy consumption in plastics processing. The new Xp series of valve gate nozzles from Oerlikon HRSflow is designed to withstand high filling pressures up to 2200 bar and enables fast injection and cycle times in a stable process with high part weight consistency. Applications of Oerlikon FLEXflow's hot runner technology and other advanced hot runner solutions specifically designed for PCR materials and biopolymers are on display on the stands of several partner companies.

Oerlikon HRSflow

Tel: +39 0422 750 127

Fax: +39 0422 750 303

E-mail: chiara.montagner@oerlikon.com

Website: www.oerlikon.com/hrsflow

Booth: 1D10

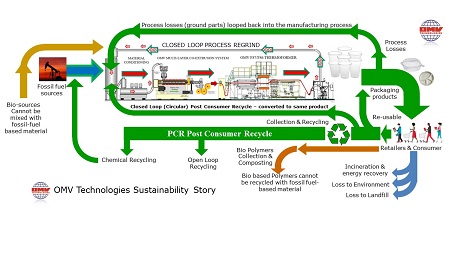

OMV Technologies: Thermoforming machines and turn-key systems

OMV Technologies LLC, leading supplier of thermoforming and extrusion machinery to the global plastics packaging industry, presents its latest technologies and sustainability efforts which are supporting processors and brand owners in their transition to a circular economy. As a leading provider of turnkey manufacturing solutions, the company will highlight its successful sustainability practices for the packaging industry. The OMV line of closed-loop machinery solutions is a reflection of the company’s commitment to sustainability. The company has forged partnerships with processors and brand owners to incorporate up to 100% post-consumer recycled (PCR) resin into products.

OMV Technologies Inc.

Tel: +1-833 626 7872

Fax: +1-888 507 0791

E-mail: info@omvtechnologies.com

Website: https://omvtechnologies.com

Booth: 3B05

PLAS MEC: Mixing equipment and services

PLAS MEC is an Italian company providing a large range of mixing equipment and services for PVC, dry-blend, thermoplastic rubbers, powder coatings, masterbatch, metallic bonding and WPC. PLAS MEC sets itself apart by its proven flexiblity to provide highly customised and top performance mixing machines and soluttions to cope with whatever mixing needs any customer may have. Each key component is developed and manufactured internally; PLAS MEC can provide a complete plant or with single components that can be integrated into existing mixing systems.

PLAS MEC S.R.L.

Tel: +39 0331 301648

Fax: +39 0331 301749

E-mail: comm@plasmec.it

Website: www.plasmec.it

Booth: 9A40

Promix: Mixing, cooling equipment

Promix Solutions presents solutions for mixing, foaming and cooling of polymer melts, saving raw material costs, reducing the carbon footprint and increasing production capacity. For manufacturers of light foams, such as XPS, XPP, XPE, XPET, Promix shows how P1 cooling mix technology can be used to achieve better mechanical properties and lower foam densities. Promix Microcell Technology creates a microcellular foam structure in the polymer by adding environmentally friendly atmospheric gases (N2 and CO2). This reduces the product weight by 20 - 50 %, which leads to massive savings in raw materials. With the new Promix Microcell Technology, an important milestone was reached with regard to cell size.

Promix Solutions

Tel: +41-52 267 80 82

E-mail: r.heusser@promix-solutions.com

Website: www.promix-solutions.com

Booth: 9E18

Reifenhäuser: Digitalisation, extrusion solutions

The Reifenhäuser Group occupies 4 booths at K 2022. Under the motto "The Time is Now", the extrusion specialists show producers of films and nonwovens valuable solutions for the three major topics of the industry: sustainability, digitalisation and productivity. The main booth showcases the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units. With the help of machine exhibits, visual presentations and concrete solutions for end products, visitors will learn, among other things, how they can manufacture fully recyclable products economically, process recyclates safely, increase their output and network the entire production without becoming dependent on systems, specialists or manufacturers.

Reifenhäuser Group

Tel: +49 2241 23510-0

E-mail: purchasing@reifenhauser.com

Website: www.reifenhauser.com

Booth: 17C22

Sepro: Automation & robotic

Sepro Group presents several examples of injection moulding automation by giving visitors hands-on experience with future technological concepts including novel man-machine interface devices, total-system integration and artificial intelligence. Each demonstration cell has been designed to be both informative and easy to use for all types of visitors. K 2022 marks the debut of a new modular software architecture that enables the control of multiple pieces of robotic and auxiliary equipment via a single central control system. In one moulding cell, for instance, the system will not only control a Sepro 5X-25 Cartesian robot and a 6X-140 six-axis articulated-arm unit, but also manage all additional peripheral devices.

Sepro Group

Tel: +33-2 5145 4600

Website: www.sepro-group.com

Booth: 12A49

Wilmington Machinery: Low pressure injection moulding machines

Wilmington’s line of General-Purpose Structural Foam Machines has had a major overhaul with new elevated designs. The elevated design allows for large overhanging moulds to clear the floor and part removal under the platen. The updated controls package offers large touch screens with configurable split screens, multi-function trend analysis screens that can be customised, and OEM trends that can be selected to monitor the process. With the addition of remote connectivity, trouble shooting and 24/7 support is a breeze. Wilmington’s Rotary Blow Moulders can run single, dual, or even triple parison. With a Wilmington wheel, it becomes possible to run 2-3 bottles from the same machine without changing moulds.

Wilmington Machinery

Tel: +1-910 452 5090

E-mail: jboos@wilmingtonmachinery.com

Website: wilmingtonmachinery.com

Booth: 13A89-18

WM Thermoforming: Thermoforming solutions

WM participates with machine demonstrations – live and remote. Special highlights are the new thermoforming solutions, test results on new materials, interesting insights into the plastic industry and much more. Another topic is the performance improvements on WM machines with the new version of the flagship thermoforming machine, the FC 780 E on centre stage. The new version also features noteworthy improvements in software (i.e. easier human-machine interaction), rationalisation, and aesthetics. WM also presents a new improved stacking system (currently patent pending), that will shake up the performances on tilting machines.

WM Thermoforming Machines

Tel: +41-91 640 7050

E-mail: sales@wm-thermoforming.com

Website: www.wm-thermoforming.com

Booth: 3A16

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login