SHORTER delivery time and endurable quality are favored and trusted by vertical machine center builders, accordingly, around 80% of Kenturn spindle products are for OEMs with specific order requests. Only about 20% of Kenturn spindles are for Kenturn's own specifications. The company’s products are used in turning centers, machine centers, and precision grinders, and end users include manufacturers from IC, semiconductor, and automotive industries.

SHORTER delivery time and endurable quality are favored and trusted by vertical machine center builders, accordingly, around 80% of Kenturn spindle products are for OEMs with specific order requests. Only about 20% of Kenturn spindles are for Kenturn's own specifications. The company’s products are used in turning centers, machine centers, and precision grinders, and end users include manufacturers from IC, semiconductor, and automotive industries.

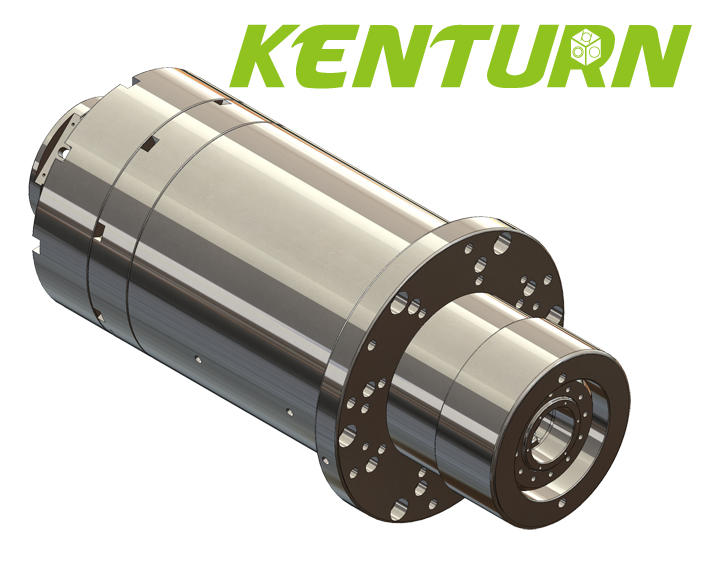

This time in TIMTOS 2015, Kenturn promotes its built-in motor spindle MVB1318A. This spindle product is able to cool the axis and is able to reduce thermal deformation issues, by using the Germany made OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand for long-term cutting operation missions. The motor power of the spindle is up to 25KW, and the speed reaches to 18,000 RPM. With dualdrive chunk, this product can be used in vertical machining centers and medium gantry machine.

Reinforced quality and extended production line

A manager of Kenturn said that, in order to manage all the production, Kenturn must cooperates intently with all outsourcing lines and extend in-house production lines for having a full control of the productivity. Now the company has built a new plant near the old one which covers an area of 50,000 square meters. “We expect that the new plant to bring us more than 100% upgraded capacity with a proposed 3,000 spindles per month," he addressed during the interview.

Employee development

In 2014, the company had to operate 24 hours to keep up with the high demands from the U.S. As a result, Kenturn recruits people from different backgrounds regardless of their past work experience in order to increase its productivity. By doing so, the company adopts strict training for ensuring employee quality. It takes about 3 years to train a qualified "Kenturnee", and it begins with frame reading and milling training, the very fundamentals for on site operators. There were about 120 employees in 2014 with an average age of 35 years old.

Aside from its internal training program, Kenturn also works with government founded research institutes in Taiwan, the Precision Machinery Research Development Center (PMC), to improve employee quality. The education is highly admired by Mr. Yeh as this is a highly focused and plant-specific subject, so Kenturn appreciates PMC's contribution. Now, stated by Kenturn supervisor, even operators from the department of Liberal Arts are professionals like the others.

Kenturn future projects

Though being located far from the source of raw materials for their products and with transportation as an issue, Mr. Yeh has taken huge steps to develop his own up and downstream chain inside the factory. The production line extension makes Kenturn thus even more reinforced with manufacturing competence. By the soaring order requests and upgrading export percentages, Kenturn reorganizes its production lines and established new plants.

Aside from the domestic market, the company also sells its spindles to international buyers in Russia, India, Swiss and America. In the future, Kenturn will participate in various international exhibitions and work with local dealers to promote Taiwan products in the global platforms.

Kenturn Nano. Tec. Co., Ltd.

TIMTOS 2015 Booth No. A0327

Tel: +886-4 7910271

Fax: +886-4 7910272

E-mail: cnc-spindle@kenturn.com.tw

Website: www.kenturn.com.tw

Кроссовки Lifestyle

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login