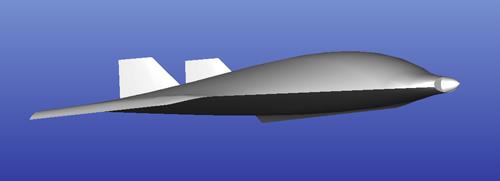

The designer of the first carbon blended-wing airplane, VX-1 KittyHawk, has won an award for its innovative use of high performance composite. VX Aerospace's revolutionary KittyHawk stands out from other aircraft due to its original blended-wing carbon structure. KittyHawk has the advantages of traditional blended-wing aircraft but enhanced by today’s state-of-the-art concepts, materials and manufacturing techniques. This one-of-a-kind configuration combines dynamic stability and aerodynamic efficiency.

Also, the use of high-performance composites has made the structure achieve low density, high damage tolerance and require fewer parts. VX Aerospace has partnered with CHOMARAT, whose C-Ply reinforcement made it structurally possible to develop the KittyHawk. Other collaborators in the project are Stanford University, North Carolina State University and University of South Carolina, according to VX-Aerospace CEO Bob Skillen.

The C-Ply composite reinforcements developed by CHOMARAT are designed to optimize the fiber performance. They give the structure properties like low weight, structural efficiency, durability and make it easier to manufacture. These properties and the innovative aircraft design allow for a large payload space. Furthermore, for the same payload space, its carbon footprint can be reduced compared to other aircraft through the optional use of alternative fuels such as compressed natural gas (CNG). When CNG is used, the VX-1 KittyHawk emits 40% less pollution than other aircraft.

C-Ply is the fruit of collaborative work between CHOMARAT and Stanford University’s Dr. Steven Tsai, who developed the concept of bi-angle thin-ply NCF.

Adidas

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login