KYOCERA Corporation (NYSE:KYO) (TOKYO:6971) has announced the TN620 and PV720, a new series of hybrid cermet materials that have 50% more abrasion and fracture resistance than traditional materials for industrial cutting-tool inserts.

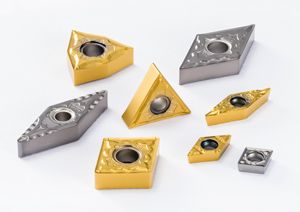

Hybrid cermet materials are used for TN620 (silver) and PV720 (gold) metal-cutting inserts

Hybrid cermet materials are used for TN620 (silver) and PV720 (gold) metal-cutting inserts

Ideal for a wide range of metal-cutting applications from high-speed to low-speed machining, the TN620 and PV720 adopt a special surface-hardening hybrid structure for a more optimal distribution of ultrafine particles within the cermet.

The internal structure uses tough cermet with superior chipping and thermal shock resistance, while the surface structure adopts a high-hardness cermet. These materials improve abrasion and fracture resistance, hardness, and toughness.

The products have a composite conventional cermet and high-melting-point metal-bonded phase for a heat-resistant hybrid bonded phase. They incorporate a uniform ultrafine-particle “hybrid-hard-phase” for enhanced flexural strength, and high-melting-point metal binding phases for greater compressive-stress effects and fracture resistance.

The PV720 also uses the proprietary Megacoat Nano. This multilayer coating technology, which is utilized for the first time on a cermet, increases abrasion and oxidation resistance for higher-efficiency machining with a superior surface finish.

Air Max 1 Master

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login