At SMT in Nuremberg, LPKF Laser & Electronics will be demonstrating why many companies now rely exclusively on laser systems such as LPKF MicroLine - and thus save resources and improve yields.

Compared to the beginnings of laser technology in depaneling, modern laser systems nowadays operate at a very high speed. Especially the new LPKF MicroLine 2127 system with the most powerful laser source in the series reduces the pure cutting time by up to 50% and thus also supports very high cycle times of SMT lines.

There are many other aspects in favour of laser technology for PCB man-ufacturers. Especially for high-quality printed circuit boards with high quali-ty requirements, many OEMs now prescribe laser technology for depanel-ing. Because where mechanical systems reach their limits - i.e. with high packing densities, the finest conductor paths even in the edge areas and flexible materials - the laser demonstrates its technological inherent ad-vantages and thus ensures the highest quality, efficient use of materials and minimal handling time.

The laser operates contact-free, without wear. It does not generate any heat or mechanical stress except at the desired location. Since the forces affecting the material are thus reduced to a minimum with laser technolo-gy, the good part rate rises to almost 100%.

PCB manufacturers achieve a large net benefit area, for example, when using machines from the LPKF MicroLine series. The powerful laser sepa-rates and cuts unassembled as well as single or double-sided SMD-assembled printed circuit boards precisely and gently. The laser creates any - and sometimes very complex - structures with a cut of only a mini-mum width. LPKF MicroLine systems work with virtually no dust genera-tion - and much more precisely than conventional tools such as saws, milling or punching. The dielectric properties of the material are not affect-ed.

The systems of the MicroLine series ensure clean, burr-free cuts in FR4, FR5, CEM materials, ceramics, polyimides, RF materials and other print-ed circuit board substrates. MicroLine systems integrate seamlessly into existing Manufacturing Execution Systems (MES) through suitable inter-faces and enable tracking & tracing for production runs. Reliable traceabil-ity is a particularly important point for safety-relevant applications.

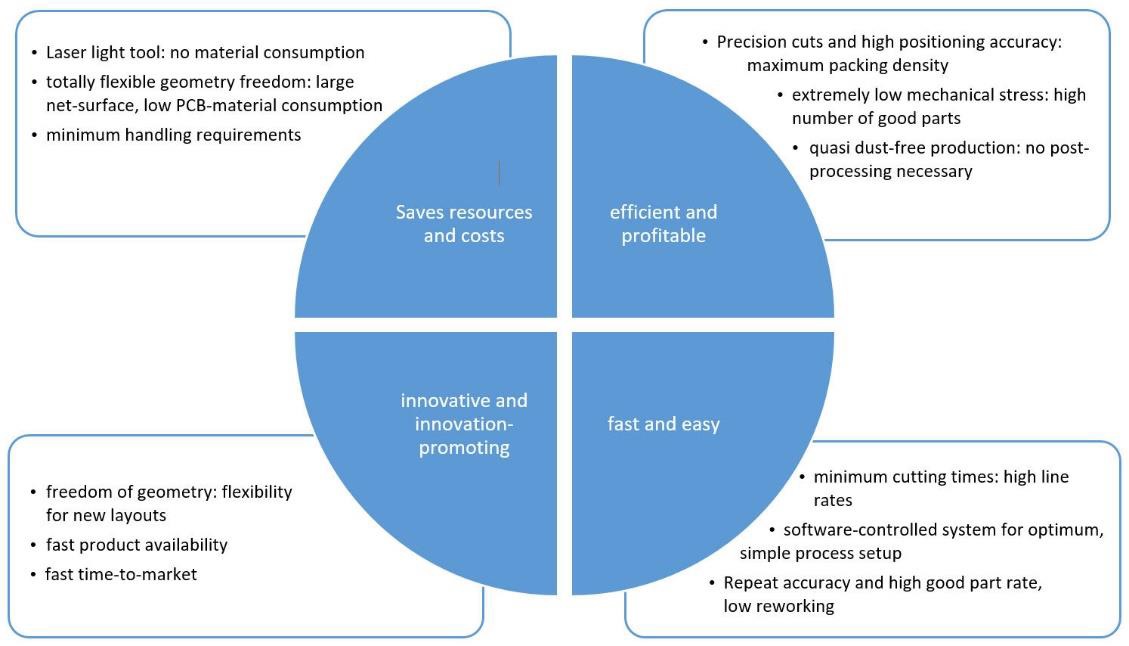

Fig. 1: In a nutshell: The advantages of the laser depaneling process

Fig. 2: A new powerful laser in the LPKF MicroLine 2000 Ci laser system ensures short cutting times and particularly effective separation of printed circuit boards.

Nike LeBron 16

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login