Automation has emerged as a game-changer for manufacturing, enabling companies to enhance productivity, reduce costs, and improve safety. Machine tools, automated assembly lines, and smart material handling systems are just a few examples of automation solutions that can significantly increase production rates while minimizing errors. Monitoring and measuring systems work seamlessly alongside human workers, augmenting their capabilities and enabling them to focus on more complex tasks.

Marposs, as a specialist in the monitoring and measuring field plays an important role in the automatization and profitability of the production.

We may consider any type of production with machine tool mass production, smaller batches or unique parts, lines, or single machine production there are issues to face that the machine alone cannot cope with, but where Marposs can supply efficacies solutions.

Marposs provides solutions that guarantee global holistic support to the whole production cycle. Starting from the machined part to the machine protection and the factory overview.

Workpiece

Before starting production, the automatic tool and machine set up will allow for precise and accurate manufacturing. Then the measurement / verification of the raw part as the final verification and the in process measurement and autonomous correction of the part will increase productivity and reduce to a very minimum bad parts an quality controls.

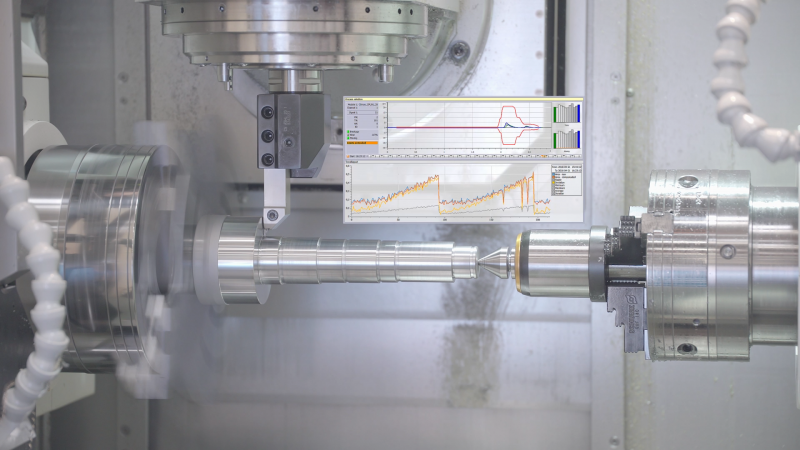

The intelligent non-manned supervision of the process plays a vital role in optimizing manufacturing operations. Through advanced monitoring and detection systems, the process can be continuously adjusted and deviations promptly identified. This intelligent supervision not only prevents unnecessary stops and crashes but also enables the system to react and optimize machining, leading to increased efficiency.

The main benefit of this section is in the yield and the cost per part since the production per time unit is increased and the need of supervision decreased.

Bad Parts, scrap, production is the other worry, by implementing the above measures consistent machining across the time and lines is ensured, minimizing the production of defective or unusable parts.

Machine

Verifying the condition of the machine itself is also a crucial aspect. This involves assessing the main mechanical elements and ensuring the precision of movements. By regularly evaluating and maintaining the machine, manufacturers can prevent overexertion and potential damages, thus extending its lifespan and optimizing performance.

It is not only that the monitoring/measuring systems supervise the production but could show a tendency to run out of specification, in this case it will be possible to verify the precision of the machine to compensate the errors and correct the problem asuring again the correct quality.

Artis monitoring device detect the condition of the machine, in the best setups they can detect when is to be planned the preparation of the repair (purchase of spares) and when is needed to repair it. Even if most commonly the elements that are monitored are spindle and axis also others can be monitored.

The results are remarkable with a noticeable impact on the production cost by avoiding producing defective parts due to machine bad condition, reducing the maintenance to when it is really needed and avoiding the collateral damages when a given element brakes up

A remarkable and widespread feature is the avoidance of most damage in case of crashes. The system detects almost instantaneously that the machine is suffering and stops it in less than one millisecond, this reduces drastically the need of spindle maintenance, downtime and worries about machine precision degradation. It is so effective that most clients once they know the system is known they cann’t conceive to work without it.

Factory

The Smart factory concept has unlocked unprecedented opportunities for the manufacturing sector. By integrating monitoring, measuring and testing systems in an analytic platform, manufacturers can collect real-time data on various operational parameters.

Going more in detail the Factory 4.0 tools permit to continuously optimise the performance of the production, it establishes benchmarks, and every software module identifies potential improvements in the different areas, from the machining improving the Nc Program and setups, to the tooling or the consumption of electricity. The operative aspects of the production are not neglected and the knowledge of which are the main factors the lower productivity is one of the most valuables pieces of information production could wish.

At EMO, Marposs presents new release of the C-THRU4.0 software. After 10 years of successful use in the most demanding industries we are updating it in features and technology used.

The new suite is completely new, intuitive, web-based and with new features. It consists of five modules specializing each one on an aspect of a factory and keeping a practical orientation to help the production responsible and/or engineers.

It highlights the process anomalies and through a friendly graphic interface lets choose the way of optimization. This reiterative process leads to an increase in the efficiency in every of the module relevant areas:

C- Analyse is designed to optimize the work of the machines (process, setup, lines, quality problems) to provide traceability of the process and for predictive maintenance.

C-Tooling is to optimize the tooling, including the tool life, usage and choice.

C-OEE is meant to prioritize and analyse the causes of the production losses mostly productivity and machine up time.

C- Energy is the tool to monitor and optimize the energy consumption of any piece of equipment, also designed for the fulfilment of the norm ISO 50001.

C-Probe enables centrally read the measurements of the touch probes and with limits to verify the results of the machining of the whole shop floor.

Marposs, as market leader, with over 70 years of experience is the only partner that masters all the involved technologies resulting in the capacity of proposing individual turn-key solutions to improve the whole production cycle in any industrial location worldwide.

Regarding the creation of systems for part measuring, tool setting, process control for virtually any CNC cutting machine tool and verification of the precision of the machine, at EMO, Marposs introduces its new visual tool setter: the VTS SF-45 Compact. The new mechanical design maintains the same repeatability and accuracy performances that remain the best on the market since its introduction. The new size, on the other hand, makes it ideal when space in the machine is an issue.

With the introduction of the SF-45 Compact, the VTS product line includes also the medium-size WF-85 and is looking forward to receiving the WF-170 at the end of 2023. With the latest developments, the VTS line becomes extremely flexible and capable to be integrated into any type of machine and cover any size of tool range.

The main objective of the touch probing systems is to optimize the production process of the machine tools, increasing both quality and quantity. Marposs Ultra Probing System is the new touch probing system with Ultra Wideband technology, a real revolution for the machine tool industry. The most important feature, which is the main advantage introduced by the Marposs Ultra Probing system, is the use of a different transmission range: in Ultra Wideband, no other physical signal can interfere with the Marposs device, which means no interference and no machine downtime.

For more information, visit us at our stand at EMO (Hall 6, Stand B52) or visit our website: https://www.marposs.com.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login