Until now, machine tool selection for the die cast market has been limited to general-purpose horizontals that possess unnecessary capabilities and result in extended cycle times in the machining of near net shape die cast parts.

To address the cycle time issue, Makino has re-evaluated each of the major castings using a Intelligent R.O.I [Reduction of Inertia] design philosophy. The new design provides superior linear and radial agility and acceleration.

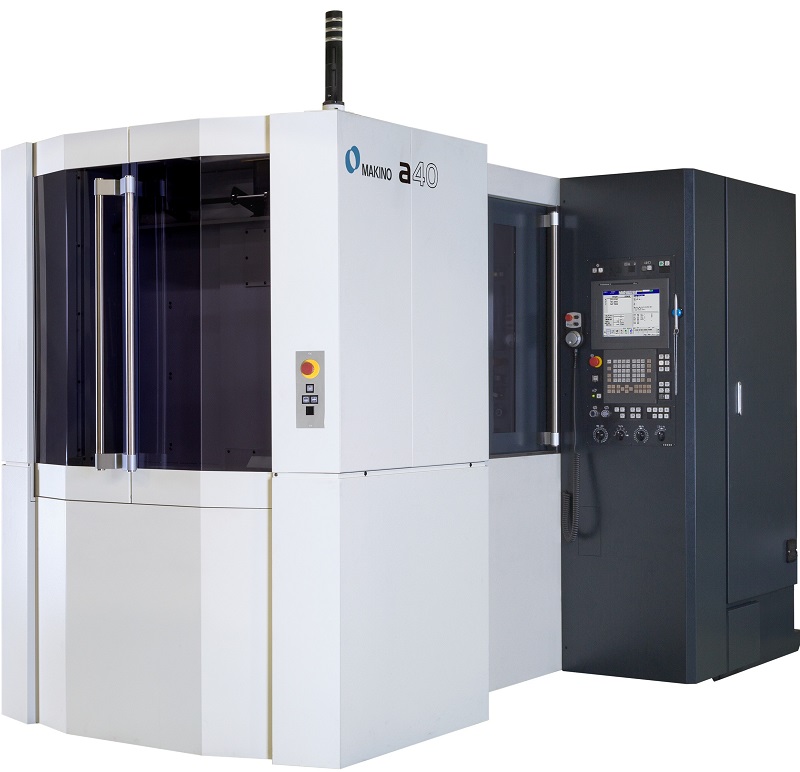

Machining center for die-cast parts

The a40 is a horizontal machining center purpose-built for non-ferrous die-cast parts machining. It addresses the unique needs of the die cast market by enhancing machine attributes most critical to improving productivity and per-piece costs in the machining of near net shape die-cast aluminium parts.

Die cast manufacturers now have a machine that is designed specifically with their production goals in mind. The machine’s ability to reduce part machining cycle time not only cuts down on per-piece cost, but also has far-reaching savings affecting capital investment, labour, floor space, utility consumption and durable tooling.

The a40 offers a 400-mm pallet with a workpiece capacity of 630 mm (24.8 inches) in diameter by 900 mm (35.4 inches) tall, making it an ideal platform for die cast parts commonly machined in the automotive and consumer product industries. Axis travels of the machine are 560 mm (22.0 inches), 640 mm (25.2 inches) and 640 mm (25.2 inches) in the X, Y and Z planes, respectively. Maximum payload is 400 kg (880 lbs). The a40 also offers numerous features and capabilities for improved utilisation and reductions in non-cut time, including a 40-position automatic tool changer and an automatic pallet change system ensure uninterrupted operation.

Intelligent R.O.I. Design

The Intelligent R.O.I. (Reduction of Inertia) design is a collection of innovative technologies designed to slash un-productive non-cut times from part processes. Through this unique design strategy the a40 is able to provide: 1) Responsive CAT40 spindle acceleration to 12,000 rpm in 0.5 seconds. 2) Quick completion of common tapping operations with 6,000-rpm rigid tapping synchronisation speed. 3) An average of 29% faster time to full rapid traverse rate, minimising common feature to feature positioning time. 4) Optimal acceleration performance of multiple machine systems with evaluation of fixture and tool weights through Inertia Active Control (IAC) technology.

Reliability

Unexpected down time is devastating to high-volume die cast production machining. As such, the reliability of the machining system is paramount. The a40 utilises several of Makino’s 1-Series horizontal machining centres. Systems like single-piece X- and Z-axis covers, centre trough chip and coolant management and dual supported ATC mechanisms provide exceptional reliability throughout the life of the machine. The a40 leverages these proven technologies, but then advances reliability with a host of new systems.

Engineering services and automation solutions

For many die cast part manufacturing facilities, machining is a secondary capability that demands specialised labour skillsets and expertise. Machine shops seeking to maximise the productive benefits of the a40 can turn to Makino for engineering support that maximises the productive capabilities of their machine investment.

Makino Engineering Services has experienced engineers and project managers that can manage every step of a project with single-point contact, project engineering, on-site supervision and post-installation training and support. Hundreds of manufacturers in need of integrated flexible manufacturing solutions have taken advantage of these services, each benefiting from guaranteed cycle times, Cpk and cost per part that meet or exceed their production goals.

With Makino automation integration services, manufacturers are able to combat fierce pricing pressures from low-labour-cost countries by providing complete automated cells and systems. Whether demands call for simple machine tending or complex high-volume robotic cells, Makino's automation integration services offer the equipment, skills and manpower necessary to reduce labour costs, increase throughput, ensure and enhance part quality, all while retaining the flexibility to adapt quickly to changing volumes or new parts.

Click to view E-zine:International Metalworking News for Asia – Dec issue

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login