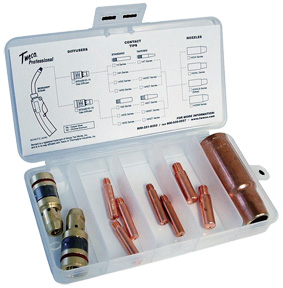

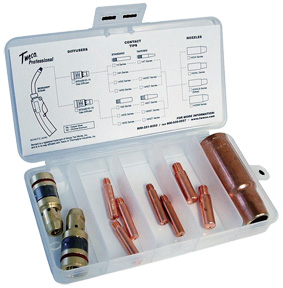

Many consider MIG gun consumables to be a commodity-- a simple throw-away item. Little do they know that these components play a critical role in achieving good welding performance and quality. They can also affect the overall productivity and cost of your welding operation, often in some rather subtle ways. For both reasons, it is crucial to find the best possible, longest-lasting consumables for your application and maintain them with as much care as you would to any other welding equipment. MIG gun consumables, which comprise the front-end part of the gun--the nozzle, retaining head and contact tip--pins the liner, are at the heart of the welding process. These components are responsible for properly feeding the welding wire and for establishing the electrical conductivity necessary to create the arc. While the welding power source you use undoubtedly influences your operation's performance, so too can your consumables. In fact, MIG gun consumables are one of the most overlooked portions of the welding operation. Without proper installation, storage, and maintenance, these components can cause significant downtime for changeover and added cost for inventory, waste and rework. Fortunately, through a few simple measures, you can easily extend the life of these components and positively affect the efficiency and profit of your welding operation. Here's how. In the MIG welding process, the nozzle directs the shielding gas around the welding wire and arc to the weld puddle. Its purpose is to protect the weld from the atmosphere and/or other contaminants that can cause weld defects, such as porosity that can lead to costly rework. Unfortunately, due to its proximity to the weld puddle, the nozzle is a common source of spatter accumulation that can obstruct that shielding gas flow. To prevent such issues, first consider the nozzle itself. Look for a smooth, non-porous surface that is free of sharp edges or flat surfaces, as it better resists spatter accumulation and therefore, lasts longer. Also, choose nozzles that have some 'mass' to them--they should look and feel sturdy. These heavier nozzles may cost more up front, but their longevity can help prevent downtime that will likely cost you more money over time. Proper nozzle storage and handling is critical to extending the life of this component. First, keep the nozzle in the plastic packaging in which it shipped until you are ready to use it. Unwrapping the nozzle and storing it in a bin, while a common practice, causes dents and scratches on the surface of the nozzle, making i t more prone to spat ter accumulation. Nozzles that are unprotected from the environment can also accumulate air-borne contaminants or debris, which if introduced into the weld puddle may cause defects that need to be reworked. Generally, semi-automatic MIG gun applications use slip-on nozzles. When installing one, make certain to securely connect the nozzle to the retaining head to prevent shielding gas leaks that can lead to weld quality issues. Also, be mindful whether you have any debris, grease or oil on your hands or gloves. Keep the nozzle as clean as possible to prevent such contaminants from entering the weld puddle later on or causing premature failure of the component. Consider using an anti-spatter compound (gels are commonly used in semi-automatic applications) to reduce the amount of spatter that adheres to the nozzle. Apply the compound by dipping only the front inch and a half of the nozzle into the compound. Do not submerge the nozzle in the compound, as this can saturate the porous insulator inside the nozzle, causing it to fail prematurely, accumulate spatter more readily and/or create an erratic arc--all factors that lead to downtime, extra costs and waste associated with changing over to a new nozzle. Next, visually inspect the inside and outside of the nozzle periodically for spatter, ideaPuma Rihanna

Many consider MIG gun consumables to be a commodity-- a simple throw-away item. Little do they know that these components play a critical role in achieving good welding performance and quality. They can also affect the overall productivity and cost of your welding operation, often in some rather subtle ways. For both reasons, it is crucial to find the best possible, longest-lasting consumables for your application and maintain them with as much care as you would to any other welding equipment. MIG gun consumables, which comprise the front-end part of the gun--the nozzle, retaining head and contact tip--pins the liner, are at the heart of the welding process. These components are responsible for properly feeding the welding wire and for establishing the electrical conductivity necessary to create the arc. While the welding power source you use undoubtedly influences your operation's performance, so too can your consumables. In fact, MIG gun consumables are one of the most overlooked portions of the welding operation. Without proper installation, storage, and maintenance, these components can cause significant downtime for changeover and added cost for inventory, waste and rework. Fortunately, through a few simple measures, you can easily extend the life of these components and positively affect the efficiency and profit of your welding operation. Here's how. In the MIG welding process, the nozzle directs the shielding gas around the welding wire and arc to the weld puddle. Its purpose is to protect the weld from the atmosphere and/or other contaminants that can cause weld defects, such as porosity that can lead to costly rework. Unfortunately, due to its proximity to the weld puddle, the nozzle is a common source of spatter accumulation that can obstruct that shielding gas flow. To prevent such issues, first consider the nozzle itself. Look for a smooth, non-porous surface that is free of sharp edges or flat surfaces, as it better resists spatter accumulation and therefore, lasts longer. Also, choose nozzles that have some 'mass' to them--they should look and feel sturdy. These heavier nozzles may cost more up front, but their longevity can help prevent downtime that will likely cost you more money over time. Proper nozzle storage and handling is critical to extending the life of this component. First, keep the nozzle in the plastic packaging in which it shipped until you are ready to use it. Unwrapping the nozzle and storing it in a bin, while a common practice, causes dents and scratches on the surface of the nozzle, making i t more prone to spat ter accumulation. Nozzles that are unprotected from the environment can also accumulate air-borne contaminants or debris, which if introduced into the weld puddle may cause defects that need to be reworked. Generally, semi-automatic MIG gun applications use slip-on nozzles. When installing one, make certain to securely connect the nozzle to the retaining head to prevent shielding gas leaks that can lead to weld quality issues. Also, be mindful whether you have any debris, grease or oil on your hands or gloves. Keep the nozzle as clean as possible to prevent such contaminants from entering the weld puddle later on or causing premature failure of the component. Consider using an anti-spatter compound (gels are commonly used in semi-automatic applications) to reduce the amount of spatter that adheres to the nozzle. Apply the compound by dipping only the front inch and a half of the nozzle into the compound. Do not submerge the nozzle in the compound, as this can saturate the porous insulator inside the nozzle, causing it to fail prematurely, accumulate spatter more readily and/or create an erratic arc--all factors that lead to downtime, extra costs and waste associated with changing over to a new nozzle. Next, visually inspect the inside and outside of the nozzle periodically for spatter, ideaPuma RihannaMake your MIG gun consumables last

Source: Release Date:2010-11-08 274

Many consider MIG gun consumables to be a commodity-- a simple throw-away item. Little do they know that these components play a critical role in achieving good welding performance and quality. They can also affect the overall productivity and cost of your welding operation, often in some rather subtle ways. For both reasons, it is crucial to find the best possible, longest-lasting consumables for your application and maintain them with as much care as you would to any other welding equipment. MIG gun consumables, which comprise the front-end part of the gun--the nozzle, retaining head and contact tip--pins the liner, are at the heart of the welding process. These components are responsible for properly feeding the welding wire and for establishing the electrical conductivity necessary to create the arc. While the welding power source you use undoubtedly influences your operation's performance, so too can your consumables. In fact, MIG gun consumables are one of the most overlooked portions of the welding operation. Without proper installation, storage, and maintenance, these components can cause significant downtime for changeover and added cost for inventory, waste and rework. Fortunately, through a few simple measures, you can easily extend the life of these components and positively affect the efficiency and profit of your welding operation. Here's how. In the MIG welding process, the nozzle directs the shielding gas around the welding wire and arc to the weld puddle. Its purpose is to protect the weld from the atmosphere and/or other contaminants that can cause weld defects, such as porosity that can lead to costly rework. Unfortunately, due to its proximity to the weld puddle, the nozzle is a common source of spatter accumulation that can obstruct that shielding gas flow. To prevent such issues, first consider the nozzle itself. Look for a smooth, non-porous surface that is free of sharp edges or flat surfaces, as it better resists spatter accumulation and therefore, lasts longer. Also, choose nozzles that have some 'mass' to them--they should look and feel sturdy. These heavier nozzles may cost more up front, but their longevity can help prevent downtime that will likely cost you more money over time. Proper nozzle storage and handling is critical to extending the life of this component. First, keep the nozzle in the plastic packaging in which it shipped until you are ready to use it. Unwrapping the nozzle and storing it in a bin, while a common practice, causes dents and scratches on the surface of the nozzle, making i t more prone to spat ter accumulation. Nozzles that are unprotected from the environment can also accumulate air-borne contaminants or debris, which if introduced into the weld puddle may cause defects that need to be reworked. Generally, semi-automatic MIG gun applications use slip-on nozzles. When installing one, make certain to securely connect the nozzle to the retaining head to prevent shielding gas leaks that can lead to weld quality issues. Also, be mindful whether you have any debris, grease or oil on your hands or gloves. Keep the nozzle as clean as possible to prevent such contaminants from entering the weld puddle later on or causing premature failure of the component. Consider using an anti-spatter compound (gels are commonly used in semi-automatic applications) to reduce the amount of spatter that adheres to the nozzle. Apply the compound by dipping only the front inch and a half of the nozzle into the compound. Do not submerge the nozzle in the compound, as this can saturate the porous insulator inside the nozzle, causing it to fail prematurely, accumulate spatter more readily and/or create an erratic arc--all factors that lead to downtime, extra costs and waste associated with changing over to a new nozzle. Next, visually inspect the inside and outside of the nozzle periodically for spatter, ideaPuma Rihanna

Many consider MIG gun consumables to be a commodity-- a simple throw-away item. Little do they know that these components play a critical role in achieving good welding performance and quality. They can also affect the overall productivity and cost of your welding operation, often in some rather subtle ways. For both reasons, it is crucial to find the best possible, longest-lasting consumables for your application and maintain them with as much care as you would to any other welding equipment. MIG gun consumables, which comprise the front-end part of the gun--the nozzle, retaining head and contact tip--pins the liner, are at the heart of the welding process. These components are responsible for properly feeding the welding wire and for establishing the electrical conductivity necessary to create the arc. While the welding power source you use undoubtedly influences your operation's performance, so too can your consumables. In fact, MIG gun consumables are one of the most overlooked portions of the welding operation. Without proper installation, storage, and maintenance, these components can cause significant downtime for changeover and added cost for inventory, waste and rework. Fortunately, through a few simple measures, you can easily extend the life of these components and positively affect the efficiency and profit of your welding operation. Here's how. In the MIG welding process, the nozzle directs the shielding gas around the welding wire and arc to the weld puddle. Its purpose is to protect the weld from the atmosphere and/or other contaminants that can cause weld defects, such as porosity that can lead to costly rework. Unfortunately, due to its proximity to the weld puddle, the nozzle is a common source of spatter accumulation that can obstruct that shielding gas flow. To prevent such issues, first consider the nozzle itself. Look for a smooth, non-porous surface that is free of sharp edges or flat surfaces, as it better resists spatter accumulation and therefore, lasts longer. Also, choose nozzles that have some 'mass' to them--they should look and feel sturdy. These heavier nozzles may cost more up front, but their longevity can help prevent downtime that will likely cost you more money over time. Proper nozzle storage and handling is critical to extending the life of this component. First, keep the nozzle in the plastic packaging in which it shipped until you are ready to use it. Unwrapping the nozzle and storing it in a bin, while a common practice, causes dents and scratches on the surface of the nozzle, making i t more prone to spat ter accumulation. Nozzles that are unprotected from the environment can also accumulate air-borne contaminants or debris, which if introduced into the weld puddle may cause defects that need to be reworked. Generally, semi-automatic MIG gun applications use slip-on nozzles. When installing one, make certain to securely connect the nozzle to the retaining head to prevent shielding gas leaks that can lead to weld quality issues. Also, be mindful whether you have any debris, grease or oil on your hands or gloves. Keep the nozzle as clean as possible to prevent such contaminants from entering the weld puddle later on or causing premature failure of the component. Consider using an anti-spatter compound (gels are commonly used in semi-automatic applications) to reduce the amount of spatter that adheres to the nozzle. Apply the compound by dipping only the front inch and a half of the nozzle into the compound. Do not submerge the nozzle in the compound, as this can saturate the porous insulator inside the nozzle, causing it to fail prematurely, accumulate spatter more readily and/or create an erratic arc--all factors that lead to downtime, extra costs and waste associated with changing over to a new nozzle. Next, visually inspect the inside and outside of the nozzle periodically for spatter, ideaPuma Rihanna

You May Like

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login